Manufacturers achieve higher mechanical strength and dimensional precision in MIM parts by controlling sintering parameters. Direct adjustment of these variables reduces defects and increases consistency.

- Temperature, time, atmosphere, and heating or cooling rates each influence the final quality of components.

Careful attention to these factors leads to reliable performance and fewer rejected parts.

Key Takeaways

- Controlling sintering parameters like temperature, time, and atmosphere is crucial for achieving high-quality MIM parts. Proper adjustments lead to fewer defects and improved mechanical properties.

- Engineers must select the right sintering temperature for each material to maximize density and strength. Regular calibration of furnaces ensures accurate temperature profiles.

- Managing sintering time is essential. Insufficient time can lead to poor bonding, while excessive time may cause grain growth, affecting part performance.

- Atmosphere control during sintering prevents oxidation and contamination. Using inert gases like nitrogen or vacuum environments enhances part integrity and purity.

- Optimizing heating and cooling rates helps maintain dimensional accuracy and reduces the risk of defects. Gradual temperature changes prevent thermal shock and uneven shrinkage.

Sintering Parameters in MIM

Definition and Role in MIM

Sintering parameters play a central role in Metal Injection Molding (MIM) by determining the quality and performance of finished parts. These parameters refer to the specific conditions set during the sintering stage, where metal powders fuse to form a solid component. Manufacturers adjust these variables to achieve optimal results for different materials and applications.

Key sintering parameters include:

- Sintering Temperature: This is the temperature at which metal powder particles bond together. The chosen temperature directly affects the final density, strength, and dimensional accuracy of the part. Each material requires a unique temperature, which engineers determine through experimentation.

- Sintering Time: This refers to how long the metal powder remains at the sintering temperature. Longer times can increase density but may also cause excessive grain growth, which can reduce mechanical performance.

Proper control of these parameters ensures that MIM parts meet strict industry standards for strength and precision.

Impact on Microstructure and Properties

Sintering parameters influence the microstructure of MIM parts, which in turn affects their mechanical and physical properties. By optimizing these settings, manufacturers can enhance the performance and reliability of components.

- Sintering improves the microstructure by tightly bonding metal particles, reducing voids and porosity. This process increases both strength and hardness.

- Adjusting temperature, time, and atmosphere helps minimize dimensional changes while preserving mechanical properties.

- The process also enhances surface finish by eliminating roughness and porosity, which is essential for applications that demand high surface quality.

Research shows that sintering parameters such as temperature and atmosphere have a significant impact on the mechanical properties of MIM components. For example, parts sintered at different temperatures and in various atmospheres display distinct mechanical characteristics. The type of feedstock, such as carbonyl iron or grinding sludge, also affects dimensional stability and overall performance.

Careful selection and control of sintering parameters allow manufacturers to produce MIM parts with superior strength, durability, and consistency.

Key Sintering Parameters for Part Quality

Temperature Optimization

Temperature stands as one of the most influential sintering parameters in Metal Injection Molding. Engineers select optimal temperatures based on the material type to achieve maximum densification and mechanical strength. For example, 316L stainless steel requires a sintering temperature of 1250°C, while 17-4PH stainless steel benefits from a range between 650°C and 1050°C. The table below highlights optimal temperature ranges for common MIM materials:

| Material | Optimal Sintering Temperature | Temperature Range |

|---|---|---|

| 316L Stainless Steel | 1250°C | N/A |

| 17-4PH Stainless Steel | N/A | 650°C – 1050°C |

Precise temperature control ensures uniform densification and prevents defects such as incomplete bonding or excessive grain growth. Regular furnace calibration also plays a vital role in maintaining accurate temperature profiles, which directly impacts part quality.

Time Management

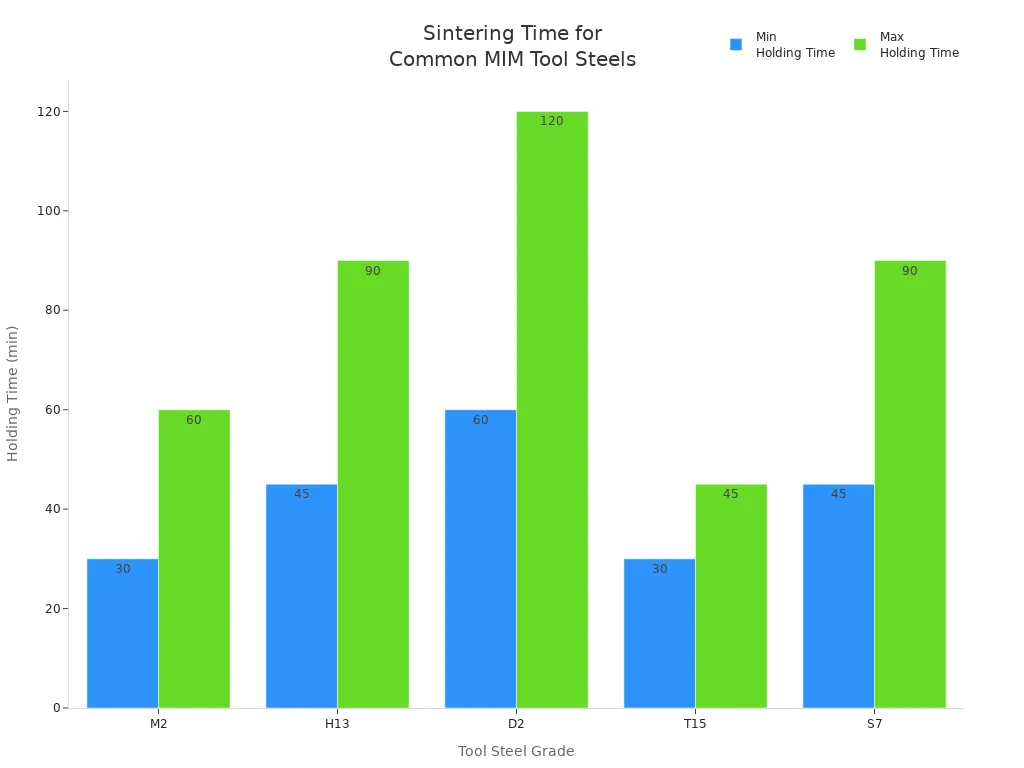

Sintering time determines how long the metal powder remains at the target temperature. Balancing this duration is essential. Insufficient time leads to poor densification, while excessive time causes grain growth and reduces mechanical properties. The following table presents recommended sintering times for popular tool steel grades:

| Tool Steel Grade | Sintering Temperature Range (°C) | Achieved Density (% of Theoretical) | Typical Holding Time (min) |

|---|---|---|---|

| M2 | 1230-1280 | 96-99% | 30-60 |

| H13 | 1200-1250 | 95-98% | 45-90 |

| D2 | 1180-1230 | 94-97% | 60-120 |

| T15 | 1250-1300 | 97-99% | 30-45 |

| S7 | 1200-1240 | 95-98% | 45-90 |

During sintering, metal powders shrink as they bond, which can alter final dimensions. Managing sintering duration helps maintain dimensional accuracy and prevents warping or surface defects. Engineers must monitor both temperature and time to ensure parts meet strict tolerances.

Atmosphere Control

Atmosphere control during sintering protects parts from oxidation and contamination. Nitrogen creates an inert environment, preventing oxidation and supporting defect-free production. Hydrogen influences carburisation and decarburisation, which affects mechanical properties. Vacuum sintering eliminates contamination and controls grain growth, ensuring high material purity. The table below summarizes the effects of different furnace atmospheres:

| Furnace Atmosphere Type | Effect on Part Quality |

|---|---|

| Nitrogen (N2) | Controls oxidation and reduction reactions, influencing overall part integrity. |

| Hydrogen (H2) | Aids in carburisation and decarburisation, affecting the mechanical properties of the sintered parts. |

| Oxidising/Reducing | Varies across furnace zones, complicating control and optimization of sintering conditions. |

- Nitrogen is used to prevent oxidation during debinding and sintering, resulting in high-quality parts.

- Vacuum sintering controls grain growth and eliminates contamination.

- The atmosphere must match the material requirements to achieve optimal results.

Careful adjustment of sintering parameters such as temperature, time, and atmosphere leads to consistent, high-quality MIM components.

Heating and Cooling Rate Adjustment

Heating and cooling rates play a critical role in the sintering process for Metal Injection Molding. Engineers adjust these rates to control the microstructure and mechanical properties of finished parts. They monitor temperature changes closely to avoid defects and ensure consistent quality.

A controlled heating rate allows for gradual temperature increase. This approach helps prevent thermal shock and uneven densification. When engineers decelerate the heating rate in specific temperature ranges, they stimulate beneficial phase transformations. These transformations enhance sintered density and improve the overall structure of the part. The table below summarizes how different heating rates affect MIM components:

| Effect of Heating Rate | Description |

|---|---|

| Sintered Density | Deceleration of heating rate in specific temperature ranges enhances sintered density through stimulated σ phase transformation. |

| Microstructural Evolution | Modulated heating rates directly correlate with microstructure and tensile properties of high-entropy alloys. |

| Densification Behavior | MSC analysis shows improved densification under modulated heating rates, optimizing microstructure and mechanical properties. |

Cooling rate adjustment is equally important. Rapid cooling can cause uneven shrinkage, which leads to residual stresses and increases the risk of cracking. Slower cooling promotes uniform stress distribution and reduces the likelihood of defects. Engineers must consider the following impacts when setting cooling rates:

- Faster cooling rates can lead to higher residual stresses due to uneven shrinkage.

- Slower cooling allows for more uniform stress distribution, reducing the risk of cracking.

- Differential shrinkage occurs when outer layers solidify faster than inner layers, creating tensile stress on the outer layers.

By optimizing heating and cooling rates, manufacturers achieve better control over Sintering Parameters. This control results in improved density, reduced defects, and enhanced mechanical performance. Careful adjustment of these rates supports the production of reliable and high-quality MIM parts.

Practical Strategies for Optimizing Sintering Parameters

Establishing Accurate Temperature Profiles

Engineers establish accurate temperature profiles in MIM sintering furnaces by designing systems with multiple heated zones. They arrange heating elements symmetrically and use sealed retorts to maintain a modified atmosphere. These methods ensure temperature uniformity throughout the furnace. Uniform temperature profiles minimize deviations, which is critical for achieving consistent shrinkage and density in all components.

Tip: Real-time monitoring of furnace temperatures helps maintain uniform heating rates and prevents distortion.

- Consistent heating rates and temperatures optimize final sintered dimensions.

- Real-time monitoring ensures uniformity across batches.

- Tight control of sintering conditions prevents shrinkage deviations.

Temperature variations can affect flow patterns and surface finish. Inconsistent mold temperatures may cause uneven cooling, which leads to defects. Engineers prioritize temperature uniformity to produce parts with reliable quality and appearance.

Setting Optimal Sintering Duration

Engineers set optimal sintering duration by analyzing the diffusion process that bonds metal particles. Sintering involves heat-based diffusion, where surface, grain boundary, and volume diffusion mechanisms work together to enhance density. Adjusting the duration allows improved diffusion and bonding, which minimizes defects.

- Improved diffusion increases part density.

- Proper duration reduces the risk of incomplete bonding.

- Controlled sintering time prevents excessive grain growth.

Engineers monitor the process to balance densification and microstructure development. They avoid short durations that cause poor bonding and long durations that lead to grain coarsening. This approach ensures parts meet mechanical and dimensional requirements.

Selecting the Right Furnace Atmosphere

Selecting the right furnace atmosphere requires careful consideration of material sensitivity and desired properties. The MIM furnace controls temperature and cover gas profile, which removes binder and ensures proper sintering. Precise atmosphere control is vital for achieving target material characteristics.

| Atmosphere Type | Key Features | Application |

|---|---|---|

| Vacuum | Low-oxygen, low-pressure (≤ 1×10⁻³ Pa ultimate, ≤ 1×10⁻² Pa working) | Prevents oxidation, improves purity |

| Argon/Nitrogen/Hydrogen | Dynamic switching, gas purification | Supports sensitive materials, controls reactions |

- Vacuum sintering provides environments that prevent oxidation.

- Furnaces support switching between argon, nitrogen, and hydrogen for different materials.

- Gas purification systems maintain atmosphere quality.

Engineers use low-oxygen environments to improve material purity. They select specific atmospheres to prevent oxidation and achieve consistent results. Atmosphere control remains a critical factor in optimizing Sintering Parameters for high-quality MIM parts.

Controlling Heating and Cooling Rates

Engineers in MIM production rely on precise thermal management to achieve consistent part quality. They monitor heating and cooling rates to control microstructure evolution and minimize defects. The process begins with gradual heating, which prevents thermal shock and supports uniform densification. Controlled cooling follows, reducing internal stresses and promoting dimensional accuracy.

- Uniform temperature distribution throughout the furnace minimizes warpage and sink marks.

- Consistent cooling prevents differential shrinkage, a common cause of warpage in MIM parts.

- Enhanced thermal management leads to improved material properties and reduced internal stresses.

Maintaining precise control over the mold temperature is crucial for achieving accurate dimensions. Controlling the cooling rate can minimize shrinkage and ensure consistent part dimensions.

Engineers also regulate the furnace atmosphere to stabilize carbon potential during sintering. Homogeneity and consistency in the furnace atmosphere are pivotal to the success of MIM manufacturing. The highest accuracy carbon control is achieved by regulating the carbon potential at the sintering temperature to the value that will lead to the desired final surface carbon concentration in the sinter body upon cooling.

The SINTERFLEX atmosphere supply system maintains the low CO+H2 concentration atmosphere necessary to stabilize carbon potential.

These best practices ensure that Sintering Parameters remain within optimal ranges, supporting the production of high-quality components.

Real-World Examples and Case Studies

Manufacturers have reported measurable improvements in MIM part quality by optimizing sintering conditions. The following case studies highlight successful strategies and outcomes:

| Case Study | Material | Density | Key Findings |

|---|---|---|---|

| Casing & Ground | MIM-Fe50%Ni soft-magnetic alloy | 7.6 g/cm³ | Optimized molding parameters resulted in defect-free parts and enhanced magnetic properties. |

| Study | Optimization Methods | Key Outcomes |

|---|---|---|

| Bone Plates | Taguchi experimental design, grey relational analysis, RMCO | Reduced black lines and meld lines, improved powder particle concentration. |

Researchers have also documented significant advances in mechanical performance and microstructural control:

| Study Title | Key Findings | Link |

|---|---|---|

| Impact of recycling on polymer binder integrity in metal injection molding | Examines the effect of powder loading and binder system on mechanical properties in MIM. | Link |

| Mechanical performance, corrosion and tribological evaluation of a Co–Cr–Mo alloy processed by MIM for biomedical applications | Highlights the importance of fine grain microstructure and zero-porosity for improved mechanical properties. | Link |

| Influence of Different Powder Conditioning Strategies on Metal Binder Jetting with Ti-6Al-4V | Discusses how powder size distribution and sintering temperature affect microstructure and mechanical properties. | Link |

| Sintering simulation and validation for the sinter-based fused filament fabrication process route | Demonstrates high accuracy in capturing microstructural evolution and macroscopic shrinkage behavior. | Link |

These examples demonstrate that careful adjustment of heating and cooling rates, combined with atmosphere control, leads to defect-free parts and enhanced mechanical properties. Manufacturers who implement these strategies consistently achieve superior results in MIM production.

Troubleshooting Sintering Parameter Challenges

Managing Density and Shrinkage Issues

Density and shrinkage problems often arise during the sintering stage of MIM. These issues can lead to dimensional inaccuracies and reduced mechanical strength. Engineers use predictive models and experimental tools to address these challenges. For example, studies on copper components have shown that vertical dilatometers help estimate shrinkage and predict relative density. Researchers also calibrate diffusion models to map densification in materials like Ti–6Al–4V. The table below summarizes key approaches:

| Aspect | Description |

|---|---|

| Study Focus | Predicting density and deformation in copper and Ti–6Al–4V components |

| Methodology | Phenomenological models, dilatometry, interrupted sintering cycles |

| Key Findings | Accurate prediction of density and shrinkage; identification of anisotropy from porosity |

Engineers monitor shrinkage throughout the process and adjust sintering parameters to maintain consistent density. They also analyze interlayer porosity and particle alignment, which can cause anisotropic shrinkage and deformation.

Preventing Warping and Cracking

Warping and cracking represent common defects in MIM sintering. These problems often result from uneven temperature distribution, rapid thermal changes, or insufficient support during processing. Engineers implement several strategies to minimize these risks:

| Strategy | Description |

|---|---|

| Temperature Uniformity | Maintains even temperatures to prevent differential shrinkage and warping. |

| Atmosphere Control | Uses inert gases to avoid unwanted chemical reactions on part surfaces. |

| Support Fixtures | Provides stability to prevent sagging or deformation. |

| Gradual Heating/Cooling | Reduces thermal stress and prevents cracking. |

| Process Monitoring | Ensures consistent heating rates and uniform temperature distribution. |

Tip: Consistent process monitoring and gradual temperature ramps help maintain part integrity and reduce the risk of defects.

Reducing Contamination Risks

Contamination during sintering can compromise part quality and mechanical properties. Engineers address this by selecting binder systems carefully. Organic binders may introduce impurities, so oxygen-free binder components are preferred to minimize oxygen contamination. High-vacuum or protective gas atmospheres, such as hydrogen, help maintain low oxygen levels during sintering. Proper ceramic furnace setters also play a role by ensuring uniform heat distribution and preventing part deformation.

- Choose binder systems that limit contamination.

- Use high-vacuum or protective gas atmospheres.

- Select ceramic setters to maintain dimensional accuracy and prevent deformation.

Maintaining a clean environment and controlling the atmosphere are essential for producing high-quality MIM parts.

Addressing Inconsistent Results

Inconsistent results in Metal Injection Molding (MIM) sintering often challenge manufacturers. Variability in part quality can stem from fluctuations in temperature, atmosphere, or feedstock composition. Engineers recognize that even minor deviations in sintering parameters may lead to unpredictable mechanical properties, dimensional inaccuracies, or surface defects.

They approach troubleshooting by first identifying the root causes. Common sources of inconsistency include:

- Temperature fluctuations within the furnace

- Non-uniform atmosphere distribution

- Variations in powder particle size or binder composition

- Inadequate process monitoring

Engineers rely on systematic process control to minimize these issues. They implement real-time monitoring systems that track temperature and atmosphere throughout the sintering cycle. Data logging allows for quick identification of anomalies. When inconsistencies arise, engineers review historical process data to pinpoint deviations.

Tip: Regular calibration of sensors and furnaces ensures accurate readings and stable process conditions.

Manufacturers also standardize raw material specifications. They use quality control checks for powder particle size, binder purity, and moisture content. Consistent feedstock properties help reduce variability in sintered parts.

The following table summarizes key strategies for addressing inconsistent results:

| Strategy | Benefit |

|---|---|

| Real-time process monitoring | Early detection of deviations |

| Sensor and furnace calibration | Improved accuracy and reliability |

| Standardized raw materials | Reduced variability in part quality |

| Statistical process control | Enhanced consistency across batches |

Engineers often apply statistical process control (SPC) methods. SPC tracks process trends and flags outliers before they affect production. By combining monitoring, calibration, and material standardization, manufacturers achieve greater consistency in MIM part quality.

Consistent results build trust with customers and support long-term production reliability.

Consistent optimization of sintering parameters delivers high-quality MIM parts with superior mechanical performance. Manufacturers who apply best practices reduce defects and increase production reliability. Ongoing monitoring and adjustment of sintering conditions remain essential for maintaining optimal results.

Regular process evaluation helps engineers identify issues early and implement improvements quickly.

📈 Continuous improvement in sintering leads to better part quality and long-term manufacturing success.

FAQ

What is the most critical sintering parameter for MIM part quality?

Temperature control stands as the most critical parameter. Engineers select optimal temperatures for each material to achieve maximum density and strength. Precise temperature management prevents defects and ensures consistent mechanical properties.

How does atmosphere selection affect sintering results?

Atmosphere selection influences oxidation, contamination, and microstructure. Nitrogen and hydrogen atmospheres protect parts from oxidation. Vacuum environments improve purity. Engineers match atmosphere type to material needs for optimal results.

Tip: Use inert gases for sensitive alloys to prevent unwanted reactions.

Why do engineers monitor heating and cooling rates during sintering?

Heating and cooling rates affect microstructure evolution and stress distribution. Gradual heating prevents thermal shock. Controlled cooling reduces residual stresses and cracking. Engineers monitor these rates to maintain dimensional accuracy and part reliability.

Can sintering parameters be adjusted for different MIM materials?

Yes, engineers tailor sintering parameters for each material. They adjust temperature, time, and atmosphere based on powder composition and desired properties. Customization ensures optimal density, strength, and surface finish for every application.

| Parameter | Customization Example |

|---|---|

| Temperature | 316L SS: 1250°C, H13: 1200°C |

| Atmosphere | Nitrogen for steel, vacuum for titanium |

| Time | Varies by alloy and part size |

Pingback: How Our Sintered Parts Manufacturer Met Bilstein's Standard