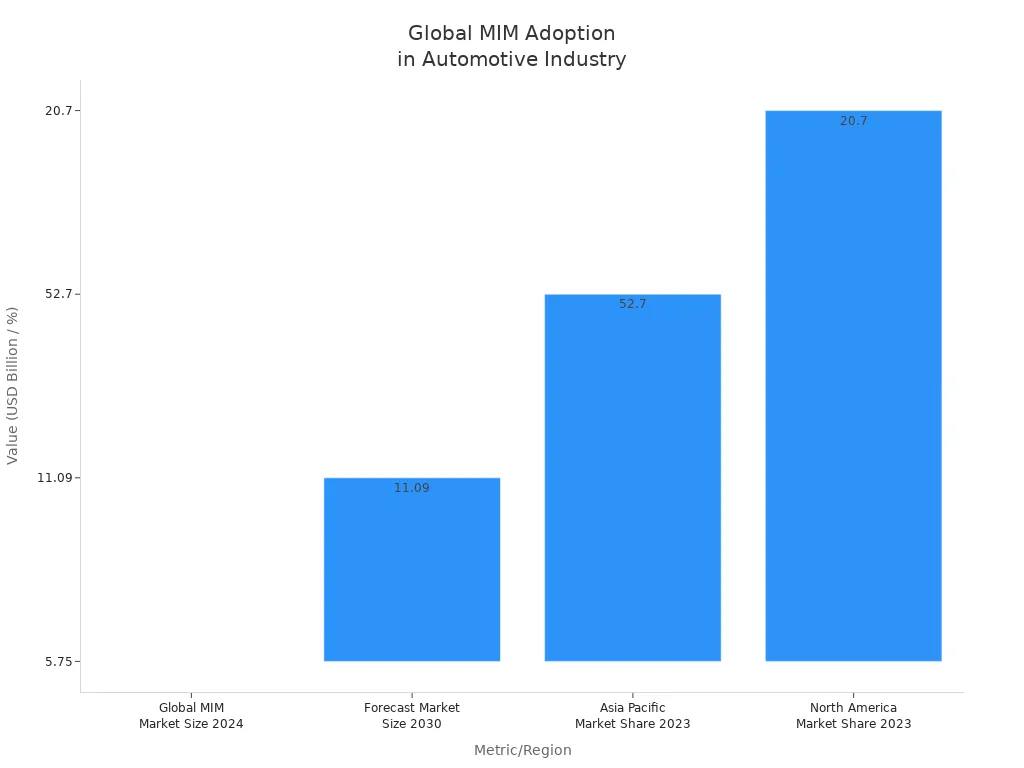

Metal Injection Molding has transformed automotive manufacturing by enabling the production of lightweight, high-strength, and complex components for engines, transmissions, and electronic systems. Manufacturers use this technology to create precise parts that improve vehicle performance and energy efficiency. The automotive industry leads global adoption, as shown in the table below:

| Metric/Region | Value/Statistic | Explanation/Context |

|---|---|---|

| Global MIM Market Size 2024 | USD 5.75 billion | Valuation of the metal injection molding market globally in 2024 |

| Forecast Market Size 2030 | USD 11.09 billion | Expected market size by 2030, indicating strong growth |

| CAGR (2024-2030) | 11.6% | Compound annual growth rate reflecting rapid adoption |

| Asia Pacific Market Share 2023 | 52.7% | Largest regional share, led by China, India, Vietnam |

MIM supports sustainability by reducing material waste and allows automakers to meet strict fuel efficiency and emission standards.

Key Takeaways

- Metal Injection Molding enables the production of strong, lightweight, and complex automotive parts that improve vehicle performance and fuel efficiency.

- The MIM process supports high-volume, cost-effective manufacturing with precise designs and reduced material waste, helping automakers meet strict quality and environmental standards.

- MIM parts replace multiple assemblies by consolidating features into single components, which lowers assembly time and enhances reliability in engines, transmissions, and safety systems.

- Automotive manufacturers use a variety of metals like stainless steel, titanium, and nickel alloys in MIM to achieve durability, corrosion resistance, and heat tolerance for different vehicle parts.

- Advanced quality control, design optimization, and surface finishing ensure MIM components meet tight tolerances and industry standards, supporting the safety and efficiency of modern vehicles.

Metal Injection Molding in Automotive Manufacturing

Key Roles in Vehicle Production

Automotive manufacturers rely on Metal Injection Molding to produce complex, lightweight, and durable metal parts at scale. The process injects a mixture of metal powder and binder into precision molds, followed by binder removal and sintering. This sequence creates dense, robust components that meet the demanding requirements of modern vehicles.

- Manufacturers use Metal Injection Molding to achieve superior design flexibility. They can create intricate, three-dimensional parts that traditional metalworking cannot easily produce.

- The process supports a wide range of materials, allowing engineers to select metals based on strength, corrosion resistance, or lightweighting needs.

- High-volume production becomes efficient, as the process reduces per-unit costs and minimizes post-processing.

- Components produced through Metal Injection Molding often replace assemblies of multiple parts, streamlining manufacturing and reducing assembly time.

- The resulting parts exhibit mechanical properties similar to wrought metals, ensuring durability in harsh automotive environments.

This integration leads to reduced production time and costs, while enabling innovative part designs that support the evolving needs of the automotive industry.

Typical Automotive Applications

Metal Injection Molding plays a vital role in manufacturing high-strength, precise automotive components. Manufacturers use this technology for a variety of applications:

- Door lock parts and steering system components benefit from the process’s ability to produce small, intricate shapes.

- Engine components, such as fuel injectors and turbocharger parts, require the strength and precision that Metal Injection Molding provides.

- Transmission system parts, including gears and levers, rely on the process for tight tolerances and durability.

- Safety-critical parts, like airbag system initiators and seatbelt mechanisms, depend on the reliability and consistency of Metal Injection Molding.

- Electric vehicle components, such as battery connectors and magnetic motor parts, take advantage of the process’s support for lightweighting and heat resistance.

By enabling the production of complex geometries and consolidating multiple features into single components, Metal Injection Molding supports the automotive industry’s goals for efficiency, safety, and innovation.

Metal Injection Molding Process for Automotive Parts

Process Steps Overview

Automotive manufacturers follow a precise sequence to produce high-quality metal components using Metal Injection Molding. The process includes several critical steps:

- Feedstock Preparation: Technicians blend fine metal powders with a thermoplastic binder to create a uniform feedstock. This mixture ensures consistent molding and material properties.

- Injection Molding: Operators heat and inject the feedstock into a mold cavity under high pressure. The mold shapes the material into a ‘green part’ that matches the final design but lacks strength.

- Debinding: Specialists remove the binder from the green part using thermal, solvent, or catalytic methods. This step produces a porous ‘brown part’ that is fragile but ready for densification.

- Sintering: The brown part is heated near the metal’s melting point in a controlled atmosphere. This process densifies the part, bonding metal particles and achieving the required mechanical properties.

- Post-Processing (Optional): Engineers may perform additional machining, heat treatment, or surface finishing to meet specific automotive standards.

Each step ensures the final part meets strict requirements for strength, accuracy, and surface quality demanded by the automotive industry.

Adaptations for Automotive Requirements

Automotive applications require unique adaptations throughout the Metal Injection Molding process. Manufacturers implement several strategies to meet industry standards:

- Material selection focuses on metals that offer safety, compatibility, and performance. Reactive or low melting point metals are avoided.

- Design engineers maintain consistent wall thickness and use rounded corners to minimize defects such as warping and sink marks.

- Process control and thoughtful mold design help reduce common defects during injection and sintering.

- Secondary operations, including coining, machining, and surface treatments, refine parts for dimensional accuracy and appearance.

- Automated dimensional inspection and non-destructive testing verify quality and ensure tight tolerances.

- High material efficiency reduces waste and supports sustainability goals important to automotive manufacturers.

- The process remains cost-effective for medium to high volume production, making it ideal for complex automotive components.

These adaptations allow manufacturers to deliver reliable, high-performance parts that meet the rigorous demands of modern vehicles.

Advantages of Metal Injection Molding for Automotive Components

Design Flexibility and Complexity

Automotive engineers value the design freedom that Metal Injection Molding provides. The process enables the creation of intricate, three-dimensional shapes that traditional metalworking cannot achieve cost-effectively. Manufacturers can produce micro-sized parts in large quantities while maintaining tight tolerances. Features such as internal and external threads, undercuts, gear teeth, slots, fins, and engravings become possible without secondary machining. This capability allows for the fabrication of multi-component parts as a single piece, reducing assembly steps and improving reliability. Automotive applications benefit from this flexibility, especially in the production of compact engine components, precision transmission parts, and lightweight elements for electric vehicles.

The ability to consolidate multiple features into one component streamlines manufacturing and supports innovative automotive designs.

Material Selection and Performance

The Metal Injection Molding process supports a wide range of advanced metals, including stainless steel, titanium, nickel, and cobalt alloys. These materials offer high strength, corrosion resistance, and wear resistance, which are essential for demanding automotive environments. The process starts with fine metal powders mixed with a polymer binder, forming a moldable feedstock. After molding, debinding, and sintering, the result is a dense, high-performance part with excellent mechanical properties and dimensional accuracy. This method allows automotive manufacturers to produce lightweight, durable parts that meet strict industry standards. The use of advanced materials also enhances the longevity and safety of critical automotive components.

Production Efficiency and Cost Savings

Metal Injection Molding delivers significant improvements in production efficiency and cost savings for automotive manufacturers. The technology enables cost-effective, high-volume production of complex, precision-engineered parts such as gears, brackets, and connectors. Automation and integration of smart technologies, including artificial intelligence and IoT devices, streamline manufacturing and reduce human error. These advancements support real-time decision-making and predictive maintenance, further boosting efficiency. Lightweight components produced through this process contribute to better fuel efficiency and lower emissions. The combination of high strength, durability, and reduced assembly needs results in a more efficient and economical manufacturing process.

Mechanical Properties and Reliability

Metal Injection Molding (MIM) delivers automotive components with impressive mechanical properties and consistent reliability. Engineers select MIM for its ability to produce dense, high-strength parts that withstand the demanding conditions found in vehicles. The process achieves material densities between 96% and 99%, which closely approach those of wrought metals. This high density ensures that MIM parts offer excellent strength, durability, and resistance to wear.

The following table compares key features of MIM with CNC machining and die casting:

| Feature | Metal Injection Molding (MIM) | CNC Machining | Die Casting |

|---|---|---|---|

| Volume Suitability | High volume production (10,000+ parts) | Low to medium volume | Medium to high volume |

| Design Complexity | Very high, capable of intricate and complex shapes | High, but less than MIM | Moderate |

| Material Density | Approximately 96-99% (some residual porosity) | 100% (solid metal) | Typically lower than MIM |

| Surface Finish | Smooth, uniform, excellent as-sintered finish | Variable, depends on machining | Good |

| Setup Cost | Moderate (tooling required, amortized over volume) | Low | High |

| Per-Part Cost | Low at scale, cost-effective for complex small parts | High, expensive for complex parts | Moderate |

MIM parts stand out for their superior wear resistance. Fine metal powders create a uniform structure, which enhances durability. The sintering process forms a honeycomb-like network, allowing the part to retain lubricants and reduce friction. This self-lubricating effect extends the lifespan of components such as gears, levers, and connectors.

- MIM enables the production of intricate shapes with tight tolerances, improving reliability in critical automotive systems.

- Excellent surface finish reduces friction, which minimizes wear and supports long-term performance.

- A wide range of material options allows engineers to tailor properties for specific automotive needs.

Automotive manufacturers trust MIM for small, complex parts that require high strength, wear resistance, and consistent quality. This reliability supports the safety and efficiency of modern vehicles.

Automotive Parts Made with Metal Injection Molding

Engine Components

Automotive engineers select Metal Injection Molding to produce a wide range of engine components that demand high precision and strength. The process enables the creation of complex shapes, such as fuel injector bodies, turbocharger vanes, rocker arms, and valve guides. These parts must withstand extreme temperatures and pressures inside the engine. MIM technology allows manufacturers to achieve tight tolerances and consistent quality, which are essential for reliable engine performance.

Engineers often choose stainless steel and heat-resistant alloys for these applications. The ability to mold intricate features directly into the part reduces the need for secondary machining. This approach saves time and ensures each component meets strict dimensional requirements. As a result, automakers can deliver engines that run more efficiently and last longer.

Note: The use of MIM in engine parts supports lightweighting strategies, which help improve fuel economy and reduce emissions.

Transmission and Drivetrain Parts

Transmission and drivetrain systems require components that combine strength, durability, and precise geometry. Metal Injection Molding offers significant advantages in this area. Manufacturers use MIM to produce gears, shift forks, synchronizer hubs, and actuator levers. These parts often feature complex internal channels or undercuts that traditional methods struggle to achieve.

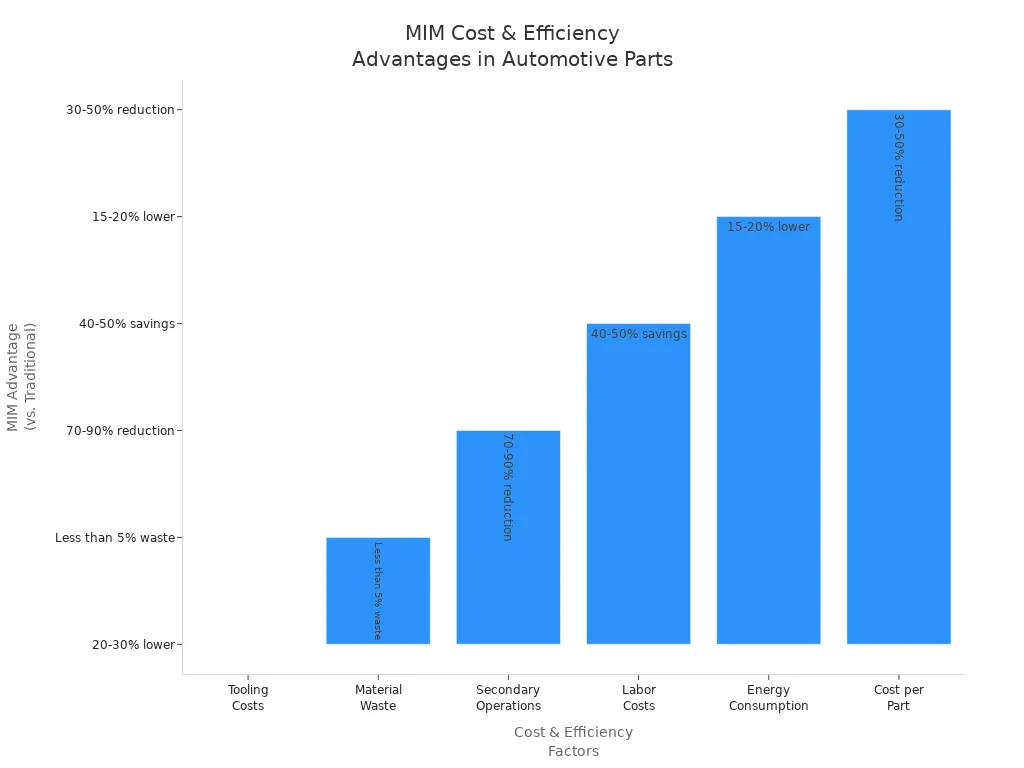

The automotive industry values MIM for its ability to reduce costs and improve quality. The following table highlights key advantages over traditional manufacturing:

| Factor | MIM Advantage |

|---|---|

| Tooling Costs | 20-30% lower than die casting due to smaller, simpler molds with less wear |

| Material Waste | Less than 5% waste compared to 30-40% in machining, leading to significant material savings |

| Secondary Operations | 70-90% reduction in secondary machining, lowering finishing costs and labor |

| Labor Costs | 40-50% savings due to automation and reduced manual work |

| Energy Consumption | 15-20% lower energy usage compared to traditional methods |

| Cost per Part (High Volume) | 30-50% cost reduction at scale, making MIM highly cost-effective for mass production |

MIM also delivers superior part quality. Components achieve dimensional accuracy within ±0.1-0.5%, which is critical for smooth transmission operation. Material density reaches 97-99% of wrought metals, providing excellent strength and wear resistance. The process supports the consolidation of multiple features into a single part, reducing assembly steps and potential failure points.

Automakers increasingly adopt MIM for these parts to meet the growing demand for lightweight, durable, and high-performance vehicles. The technology supports efficient mass production and helps manufacturers achieve better fuel efficiency and lower overall costs.

Fuel System Elements

Fuel system components must resist corrosion, maintain tight tolerances, and perform reliably under constant exposure to fuel and pressure. Metal Injection Molding enables the production of fuel injector nozzles, pump components, and sensor housings with complex geometries. These parts often require fine channels and thin walls, which MIM can achieve with ease.

Manufacturers select materials such as stainless steel and nickel alloys for their resistance to fuel and environmental factors. The MIM process ensures each part meets strict quality standards, reducing the risk of leaks or failures. By using MIM, automakers can produce fuel system elements that contribute to cleaner emissions and improved engine efficiency.

Tip: The precision and repeatability of MIM help automakers meet stringent regulatory requirements for fuel system safety and performance.

Electrical and Electronic Connectors

Automotive manufacturers rely on advanced connector technology to ensure reliable electrical performance in vehicles. Precision and durability remain essential for these components, especially as vehicles incorporate more electronic systems. Metal Injection Molding enables the production of connectors with intricate shapes and tight tolerances, supporting the demands of modern automotive design.

- Manufacturers achieve tolerances as tight as ±0.1 mm, which ensures secure connections and consistent electrical performance.

- The process supports complex geometries, allowing for miniaturized connectors used in electric vehicles and advanced driver-assistance systems.

- Optimized material usage and reduced waste, lowering production costs, making high-quality connectors accessible for large-scale manufacturing.

- Enhanced durability and efficiency contribute to longer service life and improved reliability in harsh automotive environments.

Automotive engineers select this process for connectors that must withstand vibration, temperature fluctuations, and exposure to moisture. The result is a robust electrical system that supports vehicle safety and performance.

EV and Hybrid Vehicle Parts

Electric and hybrid vehicles demand innovative solutions for lightweighting, durability, and complex part integration. Manufacturers use injection molding to produce brackets, supports, cowlings, and interior trim components that meet these requirements. Overmolding combines softer materials with rigid substrates, enhancing both aesthetics and functionality in vehicle interiors.

- Brackets and structural components produced with advanced molding techniques hold wiring, batteries, and radar/LIDAR systems securely.

- Integration of multiple manufacturing technologies, such as CNC machining and 3D printing, optimizes production efficiency and part quality.

- High-performance plastics and fiber-reinforced composites replace heavier metal parts, improving vehicle efficiency and sustainability.

- Hybrid materials combine plastic and metal, reducing weight while maintaining strength and impact resistance.

- Charging ports, radiator grilles, dashboards, and seat components benefit from precise molding, surface treatment, and rigorous quality testing.

Manufacturers collaborate with designers and material suppliers to optimize part design and material selection. This teamwork enhances production efficiency, reduces waste, and supports the development of next-generation electric vehicles.

Safety and Sensor Components

Safety and sensor systems play a critical role in modern vehicles. Manufacturers increasingly use advanced molding processes to produce sensor housings, seatbelt mechanisms, airbag system parts, and connectors for electronic safety systems. These components require high precision, durability, and complex geometries.

- The process enables the creation of small, intricate metal parts with tight tolerances, essential for reliable sensor and safety system operation.

- Part consolidation reduces vehicle weight and assembly costs, contributing to lighter, more fuel-efficient vehicles.

- Superior mechanical properties and material versatility ensure that safety components withstand demanding conditions.

- Reduced material waste and cost efficiency support large-scale production of critical safety parts.

- Braking mechanisms and transmission system components benefit from robust materials, such as low alloy steel, which enhance vehicle performance and reliability.

The precision and durability of these components directly impact vehicle safety and reliability. Manufacturers trust advanced molding techniques to deliver consistent quality for critical automotive systems.

Interior and Exterior Functional Parts

Automotive designers and engineers increasingly rely on Metal Injection Molding to produce a wide range of interior and exterior functional parts. This advanced manufacturing process supports the creation of components that demand both precision and durability. MIM stands out for its ability to deliver complex geometries and fine details that traditional metalworking methods struggle to achieve.

Manufacturers select MIM for several key reasons:

- The process enables the formation of intricate shapes, thin walls, and internal features. These characteristics are essential for parts such as seat adjustment levers, door lock actuators, and dashboard switches.

- MIM achieves high tensile strength, hardness, and fatigue resistance. These properties ensure that parts like window regulator gears and sunroof mechanisms withstand repeated use and mechanical stress.

- The technology supports the use of advanced alloys, including nickel, cobalt, and titanium. These materials provide excellent corrosion resistance, making them ideal for exterior trim pieces, mirror mounts, and wiper system components exposed to harsh environments.

- Manufacturers benefit from cost efficiency when producing small, complex parts in medium to high volumes. Once tooling costs are amortized, MIM offers a competitive advantage over machining or casting for these applications.

- The process allows for the consolidation of multiple features into a single component. This approach reduces part count, lowers assembly time, and results in lighter, more robust assemblies.

MIM empowers automakers to design functional parts that combine aesthetic appeal with mechanical performance. The process supports the integration of decorative finishes, such as chrome plating or powder coating, which enhance the appearance of interior handles, knobs, and trim bezels.

A variety of interior and exterior parts benefit from MIM technology. The following list highlights common examples:

- Seatbelt buckles and latches

- Door handle mechanisms

- HVAC vent controls

- Sunroof and window gear assemblies

- Mirror adjustment components

- Exterior emblem mounts and badges

- Wiper linkage joints

These components must perform reliably under frequent use and exposure to temperature changes, moisture, and vibration. MIM delivers the necessary strength and dimensional accuracy, ensuring long-term functionality and safety.

Automotive manufacturers continue to expand the use of Metal Injection Molding as vehicle designs evolve. The process supports the trend toward lighter, more efficient vehicles by enabling the production of compact, high-performance parts. As a result, MIM plays a vital role in shaping the modern driving experience, both inside and out.

Materials and Surface Treatments in Automotive Metal Injection Molding

Common Metals Used

Automotive engineers select metals based on the demands of each application. Titanium stands out for its exceptional strength-to-weight ratio and corrosion resistance, making it a top choice for high-performance parts. Aluminum offers a lightweight solution with good strength and excellent thermal conductivity, ideal for weight-sensitive components. Stainless steel remains the most widely used metal due to its high strength, corrosion resistance, and wear resistance. These properties make it suitable for gears, shafts, and other durable parts. Nickel alloys and tungsten also play important roles. Nickel alloys provide thermal stability and corrosion resistance, while tungsten delivers high density and wear resistance for parts exposed to extreme conditions.

| Metal | Common Automotive Applications | Key Properties Making Them Suitable for MIM |

|---|---|---|

| Stainless Steel | Gears, shafts, and various automotive parts | High strength, corrosion resistance, wear resistance, good machinability |

| Titanium | High-performance automotive components | High strength-to-weight ratio, excellent corrosion resistance |

| Aluminum | Weight-sensitive automotive parts | Lightweight, good strength, excellent thermal conductivity |

| Tungsten | High-temperature or high-wear parts | High density, wear resistance, thermal stability |

| Nickel Alloys | High-temperature resistant components | High-temperature resistance, corrosion resistance |

Surface Finishing Techniques

Surface finishing enhances both the performance and appearance of automotive components. Grinding and lapping achieve precise flatness and consistent roughness, which improves the fit of brake cylinders and gear shafts. Reaming and tapping create accurate holes and threads for secure assembly. Electropolishing removes imperfections and boosts corrosion resistance, especially for stainless steel parts. Bead blasting produces a uniform texture and prepares surfaces for coatings. Electroless nickel plating provides a hard, uniform coating that extends service life in harsh environments. Physical Vapor Deposition (PVD) applies extremely hard, thin coatings that reduce friction and wear. Each technique supports the reliability and longevity of automotive parts.

| Surface Finishing Technique | Purpose / Effectiveness | Automotive Application Examples |

|---|---|---|

| Grinding and Lapping | Precise surface flatness improves mating surfaces | Brake cylinders, pistons, gear shafts |

| Reaming and Tapping | Accurate holes and threads | Threaded features in assemblies |

| Electropolishing | Removes imperfections, enhances corrosion resistance | Stainless steel components |

| Bead Blasting | Uniform texture improves coating adhesion | Surfaces needing consistent texture |

| Electroless Nickel Plating | Hard, uniform coating extends service life | Fuel injector components, engine parts |

| Physical Vapor Deposition (PVD) | Hard, thin coating reduces friction and wear | High wear resistance parts |

Corrosion Resistance and Durability

Automotive parts must withstand harsh environments and constant use. Stainless steel and low-alloy steels provide excellent corrosion resistance and high strength, making them ideal for fuel injectors and gears. The manufacturing process produces parts with near-theoretical density, which reduces porosity and enhances mechanical properties. This dense structure increases strength, hardness, and toughness, contributing to long-lasting durability. The sintering step tightly bonds metal particles, resulting in solid parts with minimal defects. These qualities ensure that automotive components maintain performance and reliability over time, even in demanding conditions.

Note: High-density, precision-engineered parts deliver superior wear resistance and corrosion protection, supporting the safety and efficiency of modern vehicles.

Key Considerations and Challenges in Automotive Metal Injection Molding

Design for Manufacturability

Automotive engineers must address several design factors to ensure manufacturability and reliability. They focus on maintaining uniform wall thickness, typically between 1 and 6 mm, to prevent warping and ensure consistent shrinkage. Designers place parting lines and ejector pins on non-functional surfaces, which helps maintain both aesthetics and performance. Small draft angles, usually between 0.5° and 2°, assist in releasing high aspect ratio parts from molds. Fillets and radii, ranging from 0.4 to 0.8 mm, reduce stress concentrations and improve material flow. Engineers position gates at the thickest sections and on parting lines to balance material flow and minimize defects. They design holes perpendicular to parting lines and use coring to reduce material usage. Undercuts and threads can be molded directly, which eliminates secondary operations. During sintering, parts shrink by 15-20%, so engineers compensate for this reduction and add supports to prevent sagging. Avoiding common pitfalls, such as neglecting wall thickness limits or failing to account for shrinkage, ensures optimal part quality.

- Uniform wall thickness (1–6 mm) for consistent shrinkage

- Strategic placement of parting lines and ejector pins

- Use of small draft angles for easier mold release

- Incorporation of fillets and radii to reduce stress

- Gate positioning at the thickest sections

- Perpendicular holes and the use of coring

- Direct molding of undercuts and threads

- Compensation for sintering shrinkage

- Avoidance of common design pitfalls

Tip: Integrating features into the mold and optimizing part complexity can reduce assembly steps and eliminate secondary operations.

Quality Control and Testing

Automotive manufacturers implement rigorous quality control and testing procedures to ensure reliability. They begin with material inspection and verification, using spectrometers and hardness testers to confirm that raw materials meet specifications. Precision measurement tools, such as coordinate measuring machines (CMMs), calipers, and micrometers, verify dimensional accuracy. In-process monitoring uses automated sensors and machine vision systems to detect deviations in real time. Tool wear monitoring systems help prevent defects caused by worn cutting tools. Dedicated technicians perform regular inspections on all shifts, enabling immediate detection of out-of-spec conditions. Continuous communication with customers ensures that production consistently meets requirements.

| Quality Control Method | Description | Tools/Techniques Used | Benefits |

|---|---|---|---|

| Material Inspection and Verification | Ensures raw materials meet specifications | Spectrometers, Hardness testers | Consistent material performance |

| Precision Measurement and Tolerancing | Verifies dimensional accuracy | CMMs, Calipers, Micrometers | Proper fit, consistent quality |

| In-Process Monitoring | Real-time detection of deviations | Automated sensors, Machine vision | Early issue detection, reduced waste |

| Tool Wear Monitoring | Prevents defects from worn tools | Tool wear monitoring systems | Consistent part quality |

- Surface treatments, such as heat treatments and protective coatings, enhance hardness, toughness, and corrosion resistance.

- Surface finishing techniques, including electropolishing and shot blasting, improve surface quality and durability.

Cost-Effectiveness and Scalability

Automotive manufacturers choose injection molding for its precision, consistency, and cost-effectiveness in high-volume production. The process enables rapid production cycles and supports complex geometries that traditional methods cannot achieve efficiently. Compared to CNC machining and 3D printing, injection molding offers lower per-unit costs and superior scalability for mass production. Initial tooling costs are higher, but these costs are justified by the efficiency and speed of large-scale manufacturing. Material utilization remains high, with minimal waste due to powder metallurgy and net-shape forming. The following table highlights key differences between injection molding and traditional manufacturing techniques:

| Aspect | Metal Injection Molding (MIM) | Traditional Manufacturing Techniques |

|---|---|---|

| Cost-effectiveness | High for high-volume production | Often higher due to longer lead times |

| Scalability | Scalable for small to medium-sized parts | Slower and costlier for high volumes |

| Material Utilization | Minimal waste | More waste due to subtractive processes |

| Complexity & Design Flexibility | Complex shapes, fine features, tight tolerances | Limited complexity, more assembly required |

| Initial Tooling Cost | High upfront, justified by volume | Lower, but longer setup and processing |

| Production Speed | Faster cycles once tooling is established | Longer lead times |

Manufacturers benefit from rapid turnaround and cost-effective production, especially for complex automotive components requiring tight tolerances and high reliability.

Regulatory and Industry Standards

Automotive manufacturers must follow strict regulatory and industry standards when using Metal Injection Molding. These standards ensure that every component meets the safety, reliability, and quality expectations of the automotive sector. The Metal Injection Molding Association (MIMA) leads the way in setting global benchmarks for MIM processes. MIMA enforces quality control at every stage, from initial design to final sintering. It defines feedstock requirements, such as powder particle size and binder composition, which are essential for consistent and scalable production. MIMA also offers certification programs and global training workshops. These initiatives help producers, suppliers, and original equipment manufacturers (OEMs) align with best practices and maintain high standards across international supply chains.

Automotive companies also rely on established quality frameworks. The Production Part Approval Process (PPAP) stands out as a core protocol in the automotive industry. PPAP provides a structured approach to part approval, ensuring that each component meets design and functional requirements before mass production begins. This process includes documentation, testing, and validation steps that support traceability and accountability. While ISO 13485 is primarily used in medical device manufacturing, its principles of quality management and documentation often influence automotive practices, especially for critical safety components.

Consistent adherence to these standards allows manufacturers to deliver reliable, high-quality parts that integrate seamlessly into vehicles produced worldwide.

Key elements of regulatory and industry standards in automotive MIM include:

- Rigorous quality control throughout production

- Defined material and feedstock specifications

- Structured part approval and validation processes

- Certification and training for industry professionals

These standards not only support product safety and performance but also enable global interoperability. Automotive manufacturers can trust that MIM components produced in different regions will meet the same high expectations, supporting efficient and reliable vehicle assembly.

Future Trends in Automotive Metal Injection Molding

Innovations in Materials and Processes

Automotive manufacturers continue to push the boundaries of what is possible with advanced materials and process improvements. Recent developments focus on enhancing performance, efficiency, and sustainability. The industry now uses a broader range of metals, including stainless steel variants like 304L, 316L, and 17-4PH, as well as titanium, tungsten, and superalloys such as Inconel 713. These materials offer superior strength, corrosion resistance, and heat tolerance.

Process innovations have transformed manufacturing capabilities. Companies now produce parts with multiple internal channels and thin walls, achieving complex geometries that were once impossible. Part consolidation has become a key strategy, reducing assembly steps and cutting costs by up to 40%. Near-net-shape manufacturing minimizes post-processing and reduces raw material waste by about 60% compared to traditional methods.

Design and manufacturing support services have also advanced. Many suppliers offer design for manufacturability (DFM) consulting, custom alloy selection, and end-to-end solutions from prototyping to mass production. These improvements enable the creation of lightweight, high-performance components such as turbocharger vanes, valve guides, and safety-critical parts with tight tolerances and excellent mechanical properties.

Expanding Applications in Next-Gen Vehicles

The automotive sector is experiencing rapid growth in the use of powder-based manufacturing methods, especially for electric and autonomous vehicles. Demand for lightweight, high-performance, and complex-shaped components continues to rise. Manufacturers rely on these processes to produce intricate parts for electric motors, power electronics housings, and advanced driver-assistance systems (ADAS).

Next-generation vehicles require miniaturized, precise parts. Metal injection molding supports this need by enabling high-volume production with consistent quality. Integration of additive manufacturing and advanced sintering techniques allows for components with tailored properties, such as improved thermal management and strength. Hybrid manufacturing approaches combine multiple processes, resulting in unique geometries and enhanced durability.

Sustainability remains a priority. The industry adopts eco-friendly binders, recycling practices, and smart manufacturing technologies to reduce waste and support environmental goals. The Asia-Pacific region, particularly China, leads in both production volume and technological innovation. As regulatory demands for lightweighting and emissions reduction increase, these trends will continue to shape the future of automotive manufacturing.

Metal Injection Molding has revolutionized automotive manufacturing by improving efficiency, reducing material waste, and enabling precise, complex part production. The table below highlights key benefits:

| Aspect | Benefit |

|---|---|

| Manufacturing Steps | Up to 40% fewer steps |

| Material Waste | 60% less waste |

| Cost Efficiency | Up to 65% cost reduction |

| Precision | Tolerances as tight as ±0.015 mm |

Industry experts expect strong growth, driven by demand for lightweight, high-strength components and sustainability. Manufacturers continue to innovate with new materials, smart automation, and advanced design capabilities, shaping the future of automotive engineering.

FAQ

What automotive parts benefit most from Metal Injection Molding?

Engine components, transmission gears, fuel system elements, and electrical connectors benefit most. MIM enables complex shapes, tight tolerances, and high strength. Manufacturers choose MIM for parts that require precision, durability, and efficient mass production.

How does Metal Injection Molding improve automotive part performance?

MIM produces dense, high-strength parts with excellent wear resistance. The process allows engineers to design intricate features that enhance functionality. Consistent quality and material properties ensure reliable performance in demanding automotive environments.

Which metals are commonly used in automotive MIM applications?

| Metal | Key Properties |

|---|---|

| Stainless Steel | Corrosion resistance, strength |

| Titanium | Lightweight, high strength |

| Nickel Alloys | Heat and corrosion resistance |

Engineers select metals based on application requirements.

Is Metal Injection Molding cost-effective for automotive manufacturing?

MIM offers significant cost savings for high-volume production. The process reduces material waste, minimizes secondary operations, and lowers per-part costs. Manufacturers achieve efficient mass production with consistent quality, making MIM a cost-effective choice for complex automotive components.