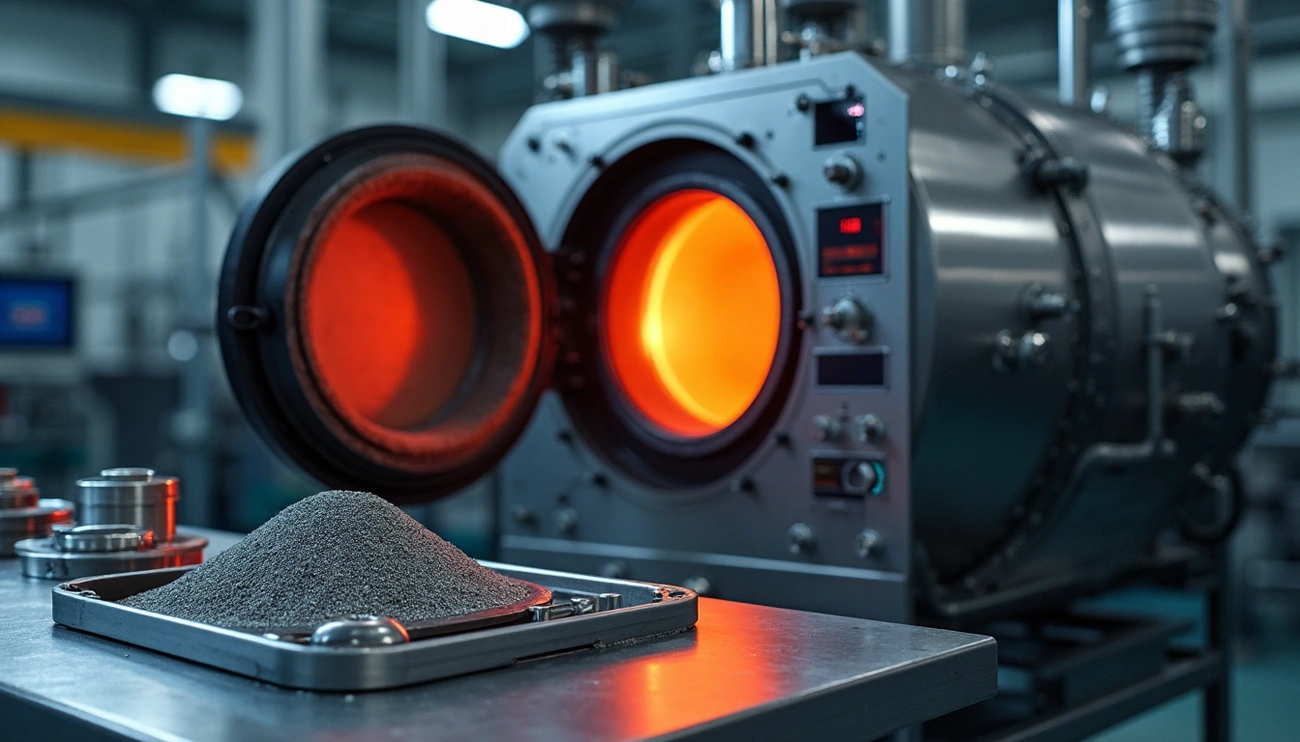

Vacuum sintering is a specialized heat treatment process that allows manufacturers to create dense, high-performance materials with improved physical and mechanical properties. This vital metallurgical technique heats material powders below their melting points in a controlled environment without atmospheric gases. The particles can then join together effectively without oxidation or contamination.

The vacuum environment provides important advantages over conventional sintering methods when producing premium-quality metal and ceramic components. Vacuum sintering furnaces maintain exact temperatures—typically ranging from 1200°C to 1700°C—to shape rather than liquefy materials. The process demands substantial technical expertise and combines knowledge of material properties, composition, preparation techniques, equipment operation, and parameter control. This detailed piece gets into the vacuum sintering process from simple principles to advanced applications and shows how this innovative technology continues to transform industries from automotive manufacturing to medical implant production.

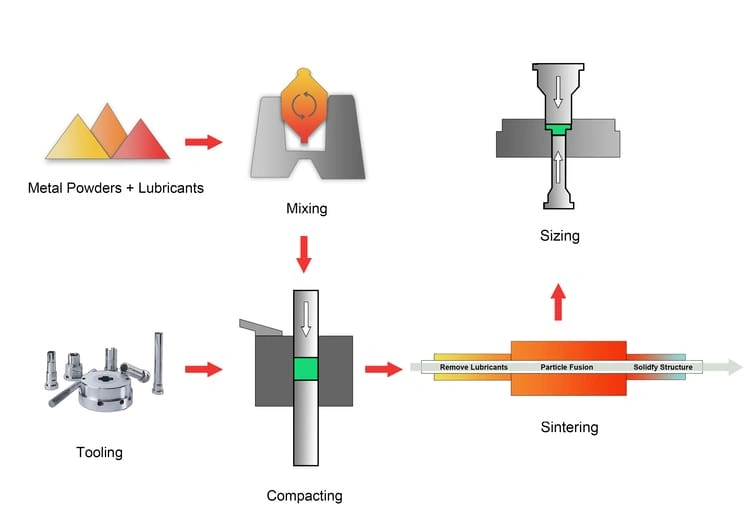

Powder Metallurgy Workflow Before Vacuum Sintering

Quality vacuum sintering starts with careful preparation of powder materials. Metal and ceramic powders go through several key steps before they reach the vacuum furnace. These steps have a big impact on the final product’s quality.

Powder mixing and ball milling for uniformity

Ball milling kicks off the powder metallurgy process. This versatile technique combines grinding and mixing of particles. The process works when spherical or cylindrical grinding media collide with powder particles. This reduces their size and creates a more uniform blend. The ball mills work by rotating plastic jars around a horizontal axis. These jars contain both the material and the grinding medium.

Manufacturers pick their milling media based on specific factors:

- Material hardness (tungsten carbide, zirconia, stainless steel, or agate)

- Size (typically 3-30mm)

- Shape (spherical or cylindrical)

Vibratory ball mills create fine powder mixtures faster and more uniformly. They combine milling and mixing in one operation. The process gives better control over particle size distribution. Manufacturers can adjust the grinding medium size, milling time, and intensity to get desired results.

Isostatic pressing for green body formation

The mixed powders then undergo isostatic pressing. This creates a “green body” – an unsintered compact strong enough to handle. The technique applies equal pressure from every direction. Pressure typically ranges from 1,035 to 4,138 bar (15,000 to 60,000 psi) at room temperature.

Two main approaches define isostatic pressing:

- Wet bag: Pressurized fluid surrounds a sealed elastomeric mold filled with powder. This works best for specialty parts and prototypes

- Dry bag: The elastomeric mold becomes part of the press and applies mostly biaxial pressure. This suits high-volume production

The process creates components with uniform density, even with large height-to-diameter ratios. These ratios are impossible with uniaxial pressing. The result is green bodies with higher density, consistent structure, and minimal particle arrangement.

Pre-sintering to remove binders and increase strength

Green compacts need pre-sintering at 500-900°C for about 30 minutes before vacuum sintering. This vital step removes binders/lubricants and builds structural strength.

Thermal debinding happens during pre-sintering. Polymeric binders turn into vapor and escape through surface pores. The heating rate needs careful control. Too much heat can create excess gas that damages parts. Gas flow removes evolved binder and stops oxidation.

Pre-sintering makes compacts stronger and safer to handle but causes little shrinkage. Powder particles form necks as mass moves from near-neck areas to neck regions. This sets up the material for vacuum sintering.

Vacuum Sintering Process Breakdown

The vacuum sintering process plays a crucial role as the transformation phase that gives prepared powder compacts their final properties through controlled heat treatment. Engineers can achieve better outcomes by understanding why it happens.

Solid-state vs liquid-phase sintering under vacuum

Two main categories define vacuum sintering processes based on how materials behave during densification. Solid-state sintering happens when the powder compact densifies completely in solid form at the sintering temperature. Liquid-phase sintering needs a liquid component during the process. The value of commercial sintered products comes much from liquid-phase sintering – about 90%. This happens because material transport in the liquid phase works hundreds of times faster than solid-state sintering.

Under vacuum conditions, solid-state sintering depends on diffusion, where atoms move from areas of high concentration at grain boundaries to low concentration areas in pores. Liquid-phase sintering uses a low-melting-point additive that turns liquid at sintering temperature. This creates capillary forces that help particles rearrange. The difference lets liquid-phase methods work at temperatures 50-100°C lower than solid-state approaches.

Densification and grain growth mechanisms

Physical and chemical processes drive vacuum sintering through viscous flow, diffusion, evaporation-condensation, dissolution-precipitation, and solid solution formation. The powder’s total surface energy decreases as these stages progress. This demonstrates compact shrinkage and strengthening at the macro level. At the micro level, we see fewer pores, changed pore shapes, and growing crystal grains.

Three distinct phases mark the densification progress. Steel pre-sintering happens between 600-900°C, where necks form between particles with minimal shrinkage. The intermediate sintering phase follows with continued neck growth and pore shrinkage, reaching about 92% density. The terminal stage sees remaining pores shrink further as material reaches its maximum density.

Preventing warping during vacuum sintering

Warping creates a major challenge during vacuum sintering because of gravity, friction, and uneven shrinkage from density variations. These forces can deform parts, leading to cracks, slumping, or parts that don’t meet tolerance requirements.

Several methods help prevent distortion. Support structures during sintering reduce gravity’s effects. Careful control of heating and cooling rates helps avoid thermal stress gradients. Uniform initial density throughout the green compact stops differential shrinkage. The right sintering supports and optimized sintering profiles reduce deformation risks by a lot.

Complex geometries benefit from strategic part placement in the furnace. Slanting parts can use gravity to guide directional shrinkage, especially when parts have varying cross-sections.

Vacuum Sintering Furnace Components and Operation

The specialized furnace equipment sits at the heart of vacuum sintering operations. These systems must deliver controlled heat treatment while maintaining precise atmospheric conditions. A deep understanding of core components helps optimize processing outcomes.

Vacuum chamber and insulation design

The vacuum chamber serves as the centerpiece where sintering takes place. These vessels can withstand extreme temperatures while maintaining vacuum conditions. Multiple layers of radiation shields reflect thermal radiation and create highly efficient insulation. This design saves energy as the surrounding water cooling system removes remaining heat. The chambers can handle high vacuum capabilities needed for aerospace, automotive, and electronics applications that require minimal contamination.

Graphite vs molybdenum heating elements

Heating elements act as the furnace’s core by converting electricity into heat within the controlled atmosphere system. Graphite heating elements have surpassed molybdenum’s popularity across heat-treating industries, though molybdenum elements were the original choice. The graphite elements handle temperatures up to 3000°C in inert conditions and come arranged in 360° circular or octagonal configurations. Molybdenum elements work effectively up to 1600°C and show a fivefold increase in resistivity during heating. All-metal hot zones are the preferred choice for biomedical applications and certain ceramics to minimize contamination risks.

Vacuum pump types: rotary vane vs turbomolecular

Multi-stage pumping systems that combine different technologies power these vacuum furnaces. Rotary vane pumps establish the original vacuum conditions as primary roughing pumps. Roots pumps or mechanical boosters step in for higher vacuum levels and increase suction volumes. The system pressures drop below the mechanical pump capabilities thanks to the diffusion pump. Sintering typically needs pressures within a few millibars. Teams select pump combinations based on gas volume, desired evacuation rates, and specific process needs.

Temperature control systems with thermocouples

The success of vacuum sintering depends on exact temperature regulation through strategically placed thermocouples. Type S thermocouples with alumina sheaths control furnaces that operate up to 2800°F. These extend 2.5-3.0 inches beyond heating elements to minimize their influence. PID controllers connect to these thermocouples and enable automated temperature profiles with programmable curves, automatic heating/cooling cycles, and alarm systems. The control systems feature over-temperature protection, broken couple alarms, and automatic power cutoff. Thermocouples need periodic replacement since their accuracy decreases over time.

Applications and Industry Use Cases

Vacuum sintering technology serves as a cornerstone process in many high-performance industries where material quality and precision matter most.

Powder metallurgy vacuum sintering in automotive

The automotive industry uses powder metallurgy vacuum sintering to manufacture transmission components that need exceptional precision. The automotive sector uses almost 70% of all structural parts produced through powder metallurgy. These sintered components achieve remarkable material utilization rates – this is a big deal as it means that they exceed 95% with minimal machining needs. Vacuum-sintered automotive parts like gears, synchronizers, and sprockets deliver stable dimensions, excellent consistency, and high precision. Transmission gears acquire superior mechanical properties through surface densification treatments and vacuum heat treatment, with surface hardness reaching 560-660 HV10. The process also creates lightweight designs that boost fuel efficiency.

Medical implants and biocompatible sintered parts

The medical device industry relies heavily on vacuum sintering to create biocompatible devices that meet strict purity standards. Titanium-based materials vacuum-sintered at 1573K show remarkable biocompatibility results from implantation tests in mice and rabbits. These materials show zero adverse tissue reactions, and new bone tissue naturally forms around the implants. Dental prosthetics and orthopedic implants benefit from vacuum-sintered components that match the hardness values of human teeth and bones.

Advanced ceramics in aerospace applications

Aerospace engineering demands vacuum-sintered advanced ceramics that deliver exceptional performance in extreme conditions. Silicon carbide and alumina ceramics handle intense temperatures and stresses in rocket nozzles and heat shields. Gas turbine engines benefit from Ceramic matrix composites (CMCs) that provide excellent thermal shock resistance and longer service life. Thrust vector control systems and structural components also rely on these materials for their high specific strength and resistance to corrosion.

Conclusion

Vacuum sintering is the lifeblood of modern materials engineering. It gives manufacturers unmatched advantages in creating premium-quality components. The controlled vacuum environment eliminates oxidation and contamination risks. It also helps optimal particle coalescence at temperatures below the melting points. This specialized heat treatment technique transforms ordinary metal and ceramic powders into exceptional components. The result is better mechanical properties and precise dimensional control.

The complete workflow needs careful attention at every stage. It starts with powder preparation through ball milling and moves to isostatic pressing for green body formation. Pre-sintering and vacuum sintering follow these steps. Product quality depends on variables like particle size distribution, pressing pressure, and sintering parameters. These factors directly affect performance characteristics.

The mechanisms behind densification need careful thought when designing sintering cycles. Solid-state sintering mainly uses diffusion processes. Liquid-phase approaches use capillary forces from melted additives to achieve faster densification at lower temperatures. This key difference explains why all but one of these commercial sintered products use liquid-phase techniques.

Equipment choice plays a big role in vacuum sintering success. Modern furnaces combine sophisticated vacuum chambers with specialized heating elements. They also feature multi-stage pumping systems and precise temperature controls to maintain optimal processing conditions. Specific applications determine the choice between graphite and molybdenum heating elements and appropriate vacuum pump setups.

Let’s take a closer look at vacuum sintering’s applications in various industries. Car makers depend on this technology to produce high-precision transmission components with material use rates above 95%. Medical professionals trust vacuum-sintered titanium implants for their exceptional biocompatibility and mechanical properties. Aerospace engineers need advanced ceramics processed through vacuum sintering that withstand extreme operational environments.

Materials science keeps advancing, and vacuum sintering technology evolves with it. Future developments might focus on using less energy, shorter processing times, and working with more materials. All the same, the basic principles in this piece will stay relevant for anyone who wants to understand or use this powerful manufacturing technique. Vacuum sintering isn’t just a processing method – it’s a gateway to creating materials with properties that once seemed impossible through conventional means.

Key Takeaways

Vacuum sintering is a specialized heat treatment process that creates high-performance materials by heating powders below their melting points in oxygen-free environments, preventing contamination while achieving superior densification.

• Proper powder preparation through ball milling, isostatic pressing, and pre-sintering is critical for achieving uniform density and optimal final product quality.

• Liquid-phase sintering accounts for 90% of commercial products because material transport occurs hundreds of times faster than solid-state methods.

• Modern vacuum furnaces require precise control of chamber design, heating elements (graphite vs molybdenum), vacuum pumps, and temperature systems for consistent results.

• Industries rely on vacuum sintering for automotive transmission components (95% material utilization), biocompatible medical implants, and aerospace ceramics that withstand extreme conditions.

• Success depends on understanding densification mechanisms, preventing warping through proper support structures, and maintaining strict process parameter control throughout the entire workflow.

This technology transforms ordinary metal and ceramic powders into exceptional components with enhanced mechanical properties, making it indispensable for applications requiring premium quality and precision in demanding environments.

FAQs

Q1. What is vacuum sintering, and how does it work? Vacuum sintering is a specialized heat treatment process that heats metal or ceramic powders below their melting points in an oxygen-free environment. This controlled atmosphere prevents contamination and oxidation while allowing particles to coalesce effectively, resulting in dense, high-performance materials with enhanced properties.

Q2. What are the key steps in the vacuum sintering process? The vacuum sintering process typically involves several steps: powder preparation through mixing and ball milling, isostatic pressing to form a green body, pre-sintering to remove binders and increase strength, and finally, the actual vacuum sintering step, where densification and grain growth occur under controlled temperature and pressure conditions.

Q3. What are the advantages of vacuum sintering over conventional sintering methods? Vacuum sintering offers several advantages, including superior purity of the final product due to the absence of atmospheric gases, better control over material properties, enhanced densification, and the ability to process materials that are sensitive to oxidation. It also allows for more precise temperature control and uniform heating.

Q4. In which industries is vacuum sintering commonly used? Vacuum sintering is widely used in industries such as automotive manufacturing for producing high-precision transmission components, medical device production for creating biocompatible implants, and aerospace engineering for developing advanced ceramics that can withstand extreme conditions.

Q5. What types of materials can be processed using vacuum sintering? Vacuum sintering can be used to process a wide range of materials, including various metals, alloys, and ceramics. It’s particularly useful for materials that are sensitive to oxidation or require high purity, such as titanium for medical implants, advanced ceramics for aerospace applications, and high-performance metal alloys for automotive parts.