CNC Machining Stainless Steel presents unique challenges for machinists. Stainless steel’s gummy nature and rapid work hardening often result in high tool wear and increased production time. Operators frequently report issues such as excessive heat buildup, difficulty achieving a quality surface finish, and the need for specialized tooling. Many shops require experienced personnel and advanced cooling methods due to stainless steel’s low thermal conductivity and toughness. Careful selection of machining parameters and expert handling remain critical to producing reliable, high-quality parts.

Key Takeaways

- Stainless steel is tough to machine due to rapid work hardening, heat buildup, and low thermal conductivity, which cause high tool wear and surface finish challenges.

- Choosing the right cutting tools, especially coated carbide tools, and optimizing cutting speeds, feeds, and depths help reduce tool wear and improve machining quality.

- Effective cooling and lubrication, such as using high-pressure coolant and proper coolant types, are essential to control heat and extend tool life.

- Careful toolpath planning and rigid workpiece fixturing minimize work hardening, vibration, and part deformation, ensuring better accuracy and surface finish.

- Different stainless steel grades vary in machinability; grades like 303 machine easier than 304 or 316, so selecting the right grade impacts productivity and tool life.

CNC Machining Stainless Steel: Why It’s Widely Used

Desirable Properties of Stainless Steel

Stainless steel stands out in manufacturing due to its unique combination of mechanical and chemical properties. Manufacturers value its high tensile strength and excellent corrosion resistance, which result from its chromium content. This material maintains durability and performance even under temperature extremes, making it suitable for demanding environments. Stainless steel also offers high precision during machining, which reduces defective parts and material waste.

Note: Stainless steel contains at least 10.5% chromium, which enhances both corrosion resistance and machinability.

Different grades of stainless steel provide specific benefits. Austenitic grades, such as the 300-series, remain non-magnetic and highly formable. Ferritic grades offer better thermal conductivity, while martensitic grades can be hardened for increased strength. Duplex stainless steels combine the advantages of both austenitic and ferritic structures, delivering enhanced corrosion resistance and strength.

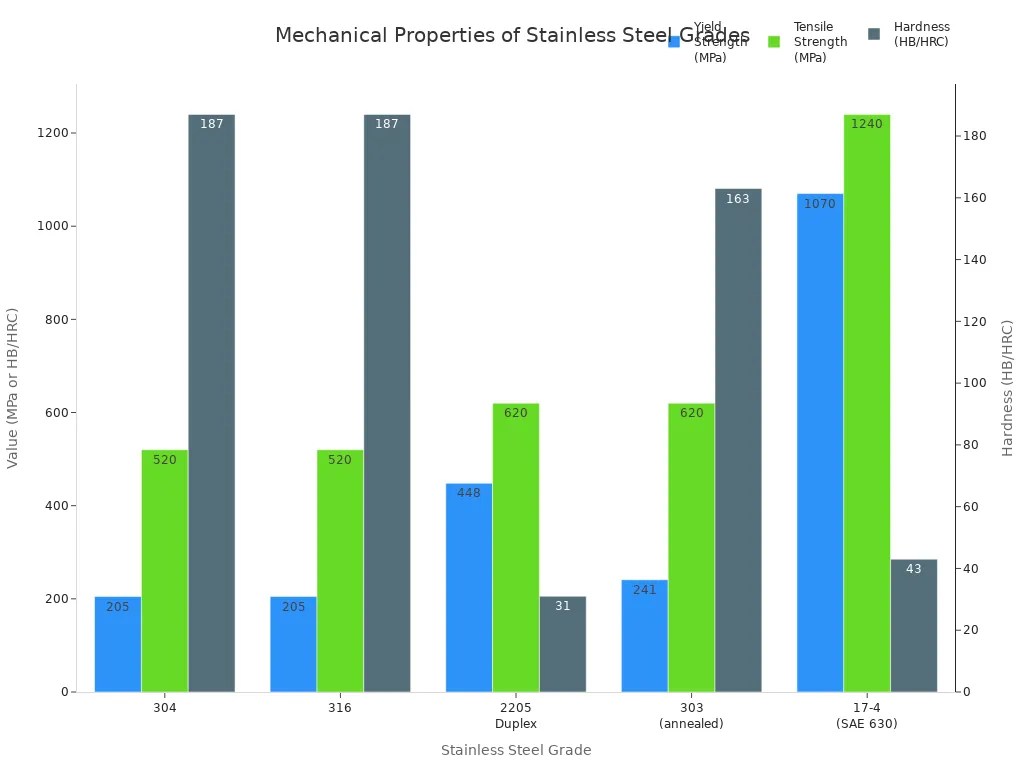

| Stainless Steel Grade | Key Mechanical Properties Relevant to CNC Machining | Applications | Yield Strength (MPa) | Tensile Strength (MPa) | Hardness |

|---|---|---|---|---|---|

| 304 | Good machinability, high corrosion resistance, good toughness | Food processing, kitchen appliances, fasteners | ≥205 | ≥520 | HB 76–187 |

| 316 | Excellent chemical resistance, higher strength at elevated temperatures | Marine, chemical equipment, pharmaceutical | ≥205 | ≥520 | HB 76–187 |

| 2205 Duplex | High fatigue strength, resistance to stress corrosion cracking | Oil & Gas, heat exchangers, marine | ≥448 | ≥620 | 31 HRC |

| 303 | Exceptional machinability, good toughness | Aerospace, fittings, gears | ≥241 (annealed), ≥414 (cold worked) | ≥620 (annealed), ≥690 (cold worked) | HB 163 (annealed), 229 (cold worked) |

| 17-4 (SAE 630) | High strength, precipitation hardening, good chemical resistance | Aerospace, nuclear waste casks, surgical instruments | ≥1070 | ≥1240 | 33–43 HRC |

Typical CNC Applications

CNC Machining Stainless Steel supports a wide range of industries that demand reliability and precision. The automotive, aerospace, medical, marine, and energy sectors all rely on stainless steel components. Manufacturers in these fields choose stainless steel for its ability to withstand harsh conditions and maintain structural integrity.

Common applications include:

- Aerospace components such as landing gear, airframes, and jet engine parts

- Medical instruments, implants, and diagnostic equipment

- Automotive engine parts, transmission components, and exhaust fittings

- Industrial machinery parts like gears, shafts, and custom fixtures

- Energy sector components for wind turbines, reactor tanks, and heat exchangers

- Food and beverage production equipment, kitchenware, and utensils

CNC Machining Stainless Steel enables the production of high-quality, long-lasting parts that meet strict industry standards. Advanced CNC machines further improve cost efficiency by reducing rework, scrap, and labor costs, while also supporting faster production cycles and real-time monitoring.

CNC Machining Stainless Steel: Key Challenges

Work Hardening

Work hardening presents a significant obstacle in CNC Machining Stainless Steel. During cutting, the material undergoes plastic deformation, which increases its hardness and the forces required for further machining. Stainless steel work hardens much faster than metals like aluminum or low-carbon steel. This rapid increase in hardness results from the alloy’s high tensile strength and poor heat conductivity. As the cutting tool moves through the material, localized heat accumulates, causing the formation of long, stringy chips and sometimes clogging the tool.

Stainless steels, especially those with high chromium and nickel content, are among the most prone to work hardening. Improper speeds, feeds, or dwell times can accelerate this effect, making the next pass even more difficult and increasing the risk of tool wear. Machinists must carefully control cutting parameters such as feed rate and depth of cut to avoid excessive work hardening. For example, in thread turning, maintaining a minimum depth of cut helps prevent the hardened layer from forming and complicating the process.

Tip: Selecting cutting tools designed for stainless steel, optimizing feeds and speeds, and using adequate coolant can help manage work hardening and extend tool life.

Work hardening not only increases tool wear but also reduces machining efficiency. The hardened surface resists cutting, forcing operators to slow down feed rates and adjust tool paths. This leads to inconsistent chip formation and a poor surface finish. To address these issues, machinists often use adaptive tool paths, preheat or anneal the material, and ensure machine rigidity to minimize vibration.

| Aspect | Effect on Tool Life and Machining Efficiency |

|---|---|

| Work Hardening | Increases hardness during cutting, causing higher cutting forces and accelerated tool wear, reducing tool life |

| Cutting Forces | Elevated due to hardened material, leading to increased power consumption and machine vibration |

| Tool Wear Mechanisms | Includes abrasive, adhesive, diffusion, and notch wear, all accelerated by work hardening |

| Surface Finish | Work hardening causes poor surface finish and problematic chip formation |

| Mitigation Strategies | Optimize tool geometry, select proper cutting parameters, use high-lubricity coolants, ensure machine rigidity |

Poor Thermal Conductivity and Heat Buildup

Stainless steel’s low thermal conductivity creates another major challenge in CNC machining. The material’s ability to transfer heat is much lower than that of carbon steel or aluminum. For example, stainless steel has a thermal conductivity of about 15 W/m·K, while carbon steel measures around 45 W/m·K, and pure aluminum reaches approximately 235 W/m·K. This means that, during machining, heat generated at the cutting zone remains concentrated near the tool and workpiece.

- Stainless steel’s low thermal conductivity causes heat to accumulate at the cutting edge.

- This heat buildup leads to thermal expansion, which can reduce dimensional accuracy and cause part distortion.

- Excessive heat may also cause sensitization, leading to intergranular corrosion and stress corrosion cracking.

- Without proper cooling and optimized cutting parameters, tool wear increases and part quality suffers.

Experienced machinists use flood coolant, adjust feed rates, and select tools with high heat resistance to manage heat buildup. Real-time temperature monitoring and adaptive machining strategies help prevent localized overheating and maintain part integrity.

Note: High thermal conductivity metals like aluminum dissipate heat quickly, reducing the risk of thermal damage. Stainless steel requires more careful heat management to avoid tool failure and part defects.

Tool Wear and Breakage

Tool wear and breakage occur more frequently when machining stainless steel than with many other metals. The material’s rapid work hardening and low machinability rating contribute to this problem. For instance, standard 304 stainless steel has a machinability rating of 30-40%, while improved grades like 303 reach up to 75%. Lower machinability means higher tool wear rates and more frequent tool changes.

| Material | Average Tool Life (minutes) | Cutting Speed (SFM) | Tool Wear Characteristics |

|---|---|---|---|

| Stainless Steel | 45 – 60 | 200 – 400 | Moderate abrasive wear, work hardening, built-up edge formation |

| Titanium | 20 – 30 | 50 – 150 | Severe chemical and thermal wear due to low thermal conductivity and high reactivity |

Several factors contribute to tool breakage during CNC Machining Stainless Steel:

- Improper speeds and feeds generate excessive heat and work hardening, leading to tool failure.

- Incorrect tool holder assembly or excessive tool stick out reduces rigidity, increasing the risk of breakage.

- Using the wrong tool or tool path can overload the cutting edge, especially with high flute count tools.

- Inadequate coolant or lubrication raises friction and heat, accelerating wear.

- Stainless steel’s low thermal conductivity and high work hardening tendency intensify these issues.

Machinists can reduce tool wear and breakage by selecting carbide tools designed for stainless steel, maintaining sharp cutting edges, and optimizing cutting parameters. Rigid tool holders, proper workholding, and effective coolant application further extend tool life and improve machining outcomes.

Achieving a Quality Surface Finish

Surface finish quality plays a critical role in the performance and appearance of stainless steel components. In CNC Machining Stainless Steel, machinists often target specific surface roughness values to meet functional and aesthetic requirements. Under standard machining conditions, stainless steel parts typically achieve surface roughness values between 0.8 µm and 3.2 µm Ra. Most applications require a finish around 1.6 µm Ra, while high-grade finishes for medical or moving parts may demand 0.8 µm Ra or better. Achieving smoother finishes below 0.8 µm Ra usually involves additional processes such as polishing or grinding.

| Surface Roughness (Ra) | Typical Stainless Steel Applications |

|---|---|

| 0.8 µm Ra | High-grade finish for stressed or moving parts; medical device housings requiring sterilization |

| 1.6 µm Ra | Common finish for parts needing tighter fits and moderate stress resistance (e.g., hydraulic rods) |

| 3.2 µm Ra | Functional finish for structural or less critical parts |

Several factors influence the final surface finish:

- Tool geometry and sharpness: Well-designed, sharp tools with optimal rake angles can improve surface finish by up to 40%.

- Tool wear: As tools wear, surface roughness increases by 20-40%, leading to uneven cutting.

- Material hardness: Stainless steel requires slower cutting speeds than softer metals to achieve similar finishes.

- Thermal effects: Heat generated during machining can cause expansion and warping, which degrades surface quality.

- Machining parameters: Lower feed rates can improve surface roughness but may increase machining time.

- Post-processing: When machining alone cannot meet finish requirements, processes like polishing or buffing enhance smoothness and corrosion resistance.

- Design considerations: Uniform wall thickness and avoiding thin sections help prevent warping and improve finish.

Tip: Regularly monitor tool wear and adjust machining parameters to maintain consistent surface quality. For critical parts, consider post-machining processes to achieve the desired finish.

Chip Control and Removal

Effective chip control is essential for maintaining tool life and part quality in CNC Machining Stainless Steel. Stainless steel tends to produce long, stringy chips that can entangle tools, cause recutting, and increase heat at the cutting zone. Industry research highlights several strategies for managing chips:

- Use specialized tool geometries, such as variable helix angles and chip breakers, to fragment chips into smaller, manageable pieces.

- Apply coatings like AlTiN or diamond-like carbon (DLC) to reduce friction and prevent chip adhesion.

- Optimize cutting speed, feed rate, and depth of cut to influence chip size and evacuation.

- Employ high-pressure coolant systems and position coolant nozzles effectively to aid chip removal and prevent entanglement.

- Utilize toolpath strategies such as trochoidal milling or adaptive clearing to improve chip evacuation.

- Implement air blast or vacuum systems for chip removal in dry or near-dry machining environments.

Inadequate chip removal leads to excessive heat at the cutting zone, which accelerates tool wear and degrades part quality. Coolant not only absorbs heat but also prevents chips from sticking to the tool and reduces friction. High-pressure coolant systems are especially important for deep holes, as they flush chips out efficiently and prevent tool jamming. When chips accumulate and recut, they stress the tool and can damage the part surface. Proper chip control ensures smoother machining, longer tool life, and higher-quality finished parts.

High Cutting Forces and Part Deformation

Machining stainless steel does not inherently require much higher cutting forces than machining other common steels. The main challenge arises from the material’s low thermal conductivity and high deformation resistance, which generate more heat during cutting. With proper tooling, lubrication, and optimized speeds and feeds, machinists can keep cutting forces manageable.

However, high cutting forces can still contribute to part deformation, especially in thin-walled or unsupported sections. The relationship between cutting force and deformation in stainless steel components is well documented:

| Aspect | Evidence Summary |

|---|---|

| Cutting Force Range | 72.66 N to 328.23 N (Arithmetic Mean), 318.36 N (Harmonic Mean) |

| Deformation Range | 0.00081 mm to 0.00567 mm (Arithmetic Mean), 0.00550 mm (Harmonic Mean) |

| Material Properties | Stainless Steel 304 Annealed: high strain hardening, poor thermal conductivity (~16 W/m·K), friction |

| Deformation Behavior | Moderate but consistent increase in deformation with higher cutting force; non-linear elastic-plastic response |

| Spatial Deformation | Minimum near chuck, maximum at unsupported zones due to loss of support and thermal effects |

| Mechanisms | Cumulative plastic strain, thermal softening, mechanical compliance changes, and tool wear |

| Implications | High cutting force leads to progressive part deformation, influenced by material microstructure and machining conditions |

Aggressive cutting parameters, such as larger depths of cut and higher feed rates, can help evacuate heat by producing larger chips. This approach minimizes tool wear and reduces the risk of work hardening. However, machinists must balance these parameters to avoid excessive deformation, especially in precision components. Proper fixturing, support, and real-time monitoring of cutting forces help maintain dimensional accuracy and prevent unwanted part distortion.

CNC Machining Stainless Steel: Practical Tips and Solutions

Choosing the Right Cutting Tools and Materials

Selecting the appropriate cutting tools and materials forms the foundation for successful CNC Machining Stainless Steel. Tool material and coating choices directly impact tool life, surface finish, and machining efficiency. Carbide tools, especially those with advanced coatings, outperform high-speed steel in durability and wear resistance. Coatings such as AlCrN and multilayer TiAlN nearly double tool life and deliver superior wear resistance compared to uncoated tools. These coatings also improve surface finish and reduce the risk of built-up edge formation.

- PVD coatings like AlCrN enhance tool longevity and maintain sharp cutting edges.

- Multilayer TiAlN coatings exhibit the lowest wear rates, making them ideal for high-volume production.

- Coatings such as AlTiN, TiCN, and TiN act as thermal barriers, reducing heat transfer to the tool and preventing hardness loss.

- Improved lubricity from these coatings lowers friction, which minimizes heat generation and chip adhesion.

- Integrating coating design with cemented carbide substrates optimizes performance for stainless steel machining.

Post-processing techniques, such as drag finishing, further enhance coating quality by reducing surface defects. These advancements allow machinists to run tools at higher speeds and feeds, achieving better productivity and consistent part quality.

Tip: Always match the tool geometry and coating to the specific grade of stainless steel and the machining operation for optimal results.

Optimizing Cutting Parameters (Speed, Feed, Depth)

Fine-tuning cutting parameters is essential for balancing productivity, tool life, and surface quality in CNC Machining Stainless Steel. Machinists often find that manufacturer-recommended speeds and feeds may not suit every application, especially with heat-resistant grades. For example, when machining AISI 321 stainless steel, reducing spindle speed below standard recommendations can prevent excessive noise, tool stress, and overheating. Lower speeds help maintain machining stability and protect the tool from premature wear.

Depth of cut (DOC) also plays a critical role in tool wear and surface finish:

- Reducing DOC minimizes tool deflection and vibration, leading to improved surface quality.

- Tool wear increases with higher loads and heat; adjusting DOC to manageable levels extends tool life.

- Deeper cuts can cause vibrations, tool deflection, and surface irregularities, especially in harder stainless steels.

- Shallow DOCs are necessary during finishing passes to achieve fine surface finishes and tight tolerances.

- Dividing machining into roughing (deeper cuts) and finishing (shallower cuts) optimizes both productivity and surface quality.

- Adequate coolant use allows for deeper cuts by managing heat buildup.

Balancing DOC with feed rate and spindle speed reduces chatter and vibration, which improves both tool life and part accuracy. New or well-maintained tools can handle more aggressive parameters, while worn tools require more conservative settings.

Note: For stainless steel, always start with conservative speeds and feeds, then gradually increase as tool and machine performance allow.

Effective Coolant and Lubrication Strategies

Proper coolant and lubrication strategies are vital for controlling heat, reducing tool wear, and ensuring dimensional accuracy in CNC Machining Stainless Steel. The choice of coolant type and application method significantly affects machining outcomes.

| Coolant Type | Oil Content | Application for Stainless Steel CNC Machining |

|---|---|---|

| MASTERALL® B1646 | High oil semi-synthetic | Used for tapping stainless steel and various steels |

| MASTERALL® 1100 | Minimal oil semi-synthetic | Suitable for milling, turning, drilling, and occasional tapping of stainless steel |

| MASTERALL® 1300 | Medium oil semi-synthetic | Effective for milling, turning, drilling, and tapping stainless steel |

| MASTERALL® 1500 | Premium low oil semi-synthetic | Used for milling, turning, drilling, threading, tapping stainless steel and high-nickel alloys |

| MASTERALL® 1700 | Chlorinated semi-synthetic | Suitable for moderate to heavy-duty machining of stainless steel |

| MASTERALL® B1977 | Low oil semi-synthetic | Used for machining stainless steel and various steels |

| MASTERALL® B1632 | Synthetic solution fluid | Used for tapping stainless steel and other metals |

| MASTERALL® SYN 20 & SYN 25 | Synthetic solution fluid | Used for tapping stainless steel and other metals |

| MASTERALL® 824 | Neat oil (non-chlorinated) | Used for machining stainless and carbon steel |

| MASTERALL® 826 | Neat oil (non-chlorinated) | Used for heavy-duty machining of stainless steel |

Water-based coolants provide excellent cooling but limited lubrication, making them less suitable for stainless steel, which demands both cooling and lubricity. Oil-based coolants offer superior lubrication, ideal for high-strength stainless steel. Synthetic coolants excel in cooling and are preferred for high-precision applications, though they require careful concentration management. Semi-synthetic coolants combine the benefits of both, offering balanced lubrication, cooling, and corrosion resistance.

The method of coolant application also influences machining performance:

- Through-tool cooling delivers coolant directly to the cutting edge, maximizing heat removal and tool life.

- Flood coolant provides good chip evacuation and cooling, but may not reach complex cutting zones.

- Minimum Quantity Lubrication (MQL) applies a fine mist, reducing coolant use and thermal shock, but may not suffice for heavy-duty operations.

- Air blast systems clear chips but offer limited cooling.

Proper coolant flow and concentration are essential for maximizing cooling efficiency and lubrication. High-pressure and through-tool systems are especially effective for stainless steel, where heat buildup and tool wear pose significant challenges. Maintaining clean and well-concentrated fluids prevents thermal cycling and micro-cracks, preserving tool integrity and part quality.

Tip: Regularly monitor coolant condition and delivery to ensure consistent performance and extend tool life.

Toolpath Planning to Minimize Work Hardening

Effective toolpath planning plays a crucial role in reducing work hardening during CNC Machining of Stainless Steel. Work hardening occurs when the material’s surface becomes harder due to repeated cutting or excessive heat. This phenomenon increases tool wear and makes subsequent machining passes more difficult. Machinists can minimize work hardening by carefully selecting and optimizing toolpaths.

Several proven strategies help reduce work hardening:

- Optimize tool paths to avoid sharp directional changes. Smooth transitions prevent sudden temperature spikes in the cutting zone.

- Use cutting tools designed specifically for stainless steel. Tools with advanced coatings reduce friction and heat buildup.

- Employ high cutting speeds. Faster speeds minimize tool dwell time and limit heat accumulation.

- Apply ample coolant or lubrication. Proper cooling dissipates heat and reduces the risk of work hardening.

- Use a low radial depth of cut, typically between 10% and 30% of the tool diameter. Combine this with higher axial depths to spread heat over a larger area.

- Employ adaptive tool paths that maintain constant tool engagement. This approach prevents sudden load spikes and extends tool life.

- Trochoidal milling and high-efficiency milling (HEM) techniques reduce heat generation. These methods use short tool engagement per pass and higher speeds with lower radial engagement.

Tip: Adaptive tool paths and high-efficiency milling not only minimize work hardening but also improve surface finish and extend tool life.

Machinists who implement these strategies achieve more consistent results. They reduce the risk of tool failure and maintain higher part quality throughout the CNC Machining of Stainless Steel process.

Workpiece Fixturing and Handling Techniques

Proper fixturing and handling techniques ensure stability and accuracy when machining stainless steel. Stainless steel’s toughness and tendency to deform under high cutting forces make secure workholding essential. Rigid fixturing prevents part movement, reduces vibration, and maintains dimensional accuracy.

Key fixturing techniques include:

- Use rigid, high-quality fixtures with hardened steel contact points. These fixtures provide stability and resist wear.

- Apply uniform clamping pressure with calibrated or torque-limiting tools. Even pressure prevents tilting or distortion of the workpiece.

- Employ dowel pins or locating stops to constrain the part mechanically. These features resist lateral cutting forces and maintain alignment.

- Orient clamps and stops to counteract the expected direction of cutting forces. This setup minimizes the risk of part movement during machining.

- Minimize unsupported areas by adding supports or backing materials. Extra support prevents vibration and deflection, especially in thin-walled parts.

- Consider thermal expansion by allowing room for material movement or using low-stress clamping. This approach avoids warping due to heat buildup.

- Use workpiece probing and verification before and during machining. Regular checks detect and correct any part movement early.

| Fixturing Technique | Benefit |

|---|---|

| Rigid fixtures with hardened points | Reduces vibration and increases stability |

| Uniform clamping pressure | Prevents distortion and maintains accuracy |

| Dowel pins/locating stops | Ensures precise alignment and resists forces |

| Supports/backing materials | Minimizes deflection in unsupported areas |

| Probing and verification | Detects movement and maintains tolerances |

Note: Proper fixturing not only improves machining accuracy but also extends tool life and reduces scrap rates.

Machinists who follow these fixturing practices achieve better results in CNC Machining Stainless Steel. They maintain tight tolerances, prevent part deformation, and produce high-quality components.

CNC Machining Stainless Steel: Grade Comparison and Machinability

303 vs. 304 vs. 316 Stainless Steel

Machinists often compare 303, 304, and 316 stainless steel when selecting materials for precision parts. Each grade offers distinct properties that affect tool wear, chip formation, and surface finish.

- Type 303 stands out for its high machinability. Manufacturers add sulfur or selenium to this grade, which promotes easy chip breakage and allows for higher machining speeds—up to 40 surface meters per minute. This modification reduces tool wear and produces a smoother surface finish.

- Type 304, a common austenitic stainless steel, lacks free-machining agents. Its higher nickel content increases toughness and work hardening, which leads to more frequent tool changes and increased downtime. Achieving a fine surface finish with 304 proves more challenging.

- Type 316 contains additional molybdenum, which enhances corrosion resistance but further reduces machinability. Like 304, it exhibits rapid work hardening and increased tool wear, resulting in a poorer surface finish.

| Stainless Steel Grade | Key Chemical Elements Affecting Machinability | Effect on Tool Wear | Effect on Surface Finish | Machinability Rating |

|---|---|---|---|---|

| 303 | Sulfur (S), Selenium (Se) | Reduced tool wear | Improved surface finish | Excellent (~70-85%) |

| 304 | Higher Nickel (Ni), no free-machining agents | Increased tool wear | Moderate surface finish | Lower (~45%) |

| 316 | Nickel (Ni), Molybdenum (Mo) | Increased tool wear | Poorer surface finish | Poor (~45%) |

Austenitic grades like 304 and 316 have machinability ratings near 45%. Their toughness and tendency to work harden increase tool wear and complicate surface finish. In contrast, 303’s machinability rating ranges from 70% to 85%, making it the preferred choice for complex parts and high-volume production.

Note: All stainless steels generate significant heat during machining, which can cause built-up edge formation and affect both tool life and part quality.

Specialty Grades and Their Machining Behavior

Specialty stainless steel grades, such as 316L, duplex alloys, and precipitation-hardened types, present unique machining challenges. These materials often exhibit strong work-hardening tendencies. As the cutting tool engages the surface, the material hardens progressively, increasing cutting forces and accelerating tool wear.

- Poor thermal conductivity, as seen in 316L (~16 W/m·K), causes heat to concentrate at the cutting edge. This heat buildup can lead to thermal expansion, affecting dimensional accuracy.

- Machining specialty grades requires careful control of cutting parameters. Operators typically use reduced cutting speeds—30% to 40% slower than carbon steel—and moderate feed rates. Multiple light passes help minimize deflection and maintain surface finish.

- Specialized tooling materials, such as carbide, ceramics, or powder metallurgy steels, withstand the abrasive and heat-intensive environment. Advanced coatings further protect tools from rapid wear.

- High-pressure coolant systems and oil-based coolants play a critical role in managing heat and improving chip evacuation.

- Machinists often rough machine parts oversized, allow for thermal stabilization, and then perform finishing cuts to achieve tight tolerances, sometimes as precise as ±0.005 mm.

Other specialty alloys, including Inconel and titanium, share similar machining difficulties. They require slower speeds, rigid setups, and generous cooling to prevent tool failure. Collaboration with alloy suppliers and technical experts helps optimize machining strategies for these demanding materials.

CNC Machining Stainless Steel: Surface Finishing and Post-Processing

Suitable Surface Finishes

Surface finishing determines both the appearance and performance of stainless steel parts. Manufacturers select from a range of techniques to meet specific requirements for corrosion resistance, cleanliness, and aesthetics. Each method offers unique benefits and suits different applications.

- Polishing creates a high-gloss, mirror-like surface. This finish improves corrosion resistance and cleanliness, making it ideal for medical devices, food processing equipment, and luxury goods.

- Bead Blasting uses pressurized glass beads to produce a consistent matte or satin finish. This process removes tool marks and burrs, enhancing visual appeal without significantly changing functional properties.

- Passivation involves a chemical bath that removes free iron from the surface. The process forms a protective chromium or nickel layer, increasing rust resistance and extending part life.

- Electroless Nickel Plating deposits a uniform nickel-phosphorous alloy layer. This finish increases hardness and wear resistance, especially for complex shapes.

- Electroplating adds metal coatings such as chrome or gold. This method enhances corrosion resistance, wear resistance, and electrical conductivity, but it can be costly and environmentally demanding.

- Powder Coating applies a dry powder that cures into a durable, impact-resistant layer. It offers a wide color range and can combine with bead blasting for a uniform appearance.

| Surface Finish Technique | Typical Outcome / Application |

|---|---|

| As-Machined Finish | Visible tool marks; cost-effective for functional parts |

| Sand Blasting | Matte, uniform finish; improves aesthetics |

| Electropolishing | Smooth, bright, corrosion-resistant finish; ideal for sterile surfaces |

| Brushed Finish | Satin sheen with fine lines; decorative use |

| Passivation | Enhances corrosion resistance without changing appearance |

| Powder Coating | Durable, colored coating; protects against corrosion |

| Electroplating | Metal coating for wear resistance and conductivity |

Note: The right surface finish balances cost, appearance, and performance for each application.

Deburring and Cleaning Methods

Deburring and cleaning ensure that stainless steel parts meet strict quality standards. Burrs, sharp edges, and contaminants can affect assembly, safety, and function. Manufacturers use several methods to address these issues.

- Manual Deburring uses files, abrasive pads, or brushes to remove sharp edges and small burrs. This method suits low-volume or complex parts.

- Mechanical Deburring employs tumbling, vibratory finishing, or abrasive blasting. These processes handle larger batches and provide consistent results.

- Thermal Deburring uses controlled explosions of gas to remove burrs from hard-to-reach areas. This technique works well for intricate geometries.

- Ultrasonic Cleaning immerses parts in a cleaning solution and uses high-frequency sound waves to dislodge particles and oils.

- Chemical Cleaning applies acids or solvents to dissolve contaminants and prepare surfaces for finishing or assembly.

Tip: Combining mechanical and chemical cleaning methods often yields the best results for high-precision stainless steel components.

Proper deburring and cleaning not only improve part appearance but also enhance performance and longevity. Clean, burr-free surfaces reduce the risk of assembly errors and ensure reliable operation in demanding environments.

CNC Machining Stainless Steel presents unique challenges, including rapid tool wear, heat buildup, and work hardening. Machinists who use targeted strategies—such as proper tool selection, optimized parameters, and effective cooling—achieve better results. These practical tips help extend tool life and improve part quality.

Consistent application of proven solutions leads to successful stainless steel machining in any industry.

FAQ

What is the best cutting tool material for stainless steel?

Carbide tools with advanced coatings, such as AlTiN or TiAlN, offer the best performance. These tools resist wear, handle high temperatures, and maintain sharpness longer than high-speed steel.

How can machinists reduce tool wear when machining stainless steel?

Machinists should use coated carbide tools, optimize cutting speeds and feeds, and apply high-pressure coolant. Regular tool inspection and timely replacement also help prevent excessive wear.

Why does stainless steel produce long, stringy chips?

Stainless steel work hardens quickly and has high ductility. These properties cause chips to form as long strings rather than breaking easily. Specialized chip breakers and proper cutting parameters improve chip control.

Which surface finish is most common for CNC-machined stainless steel parts?

| Finish Type | Typical Application |

|---|---|

| 1.6 µm Ra | General engineering parts |

| 0.8 µm Ra | Medical, moving components |

| 3.2 µm Ra | Structural, non-critical use |

Most parts require a 1.6 µm Ra finish for balanced performance and cost.