Material jetting achieves remarkable precision with ±0.1% dimensional accuracy and can reach tolerances as low as ±0.02 mm. The process works like traditional 2D printers but creates objects layer by layer in three dimensions.

Material jetting stands out as one of the seven additive manufacturing technologies. The process deposits tiny droplets of building material onto a platform. These materials harden under ultraviolet light during the manufacturing process. The technology creates exceptionally detailed, complex parts with layer heights of 16-32 microns and resolution down to 14 microns.

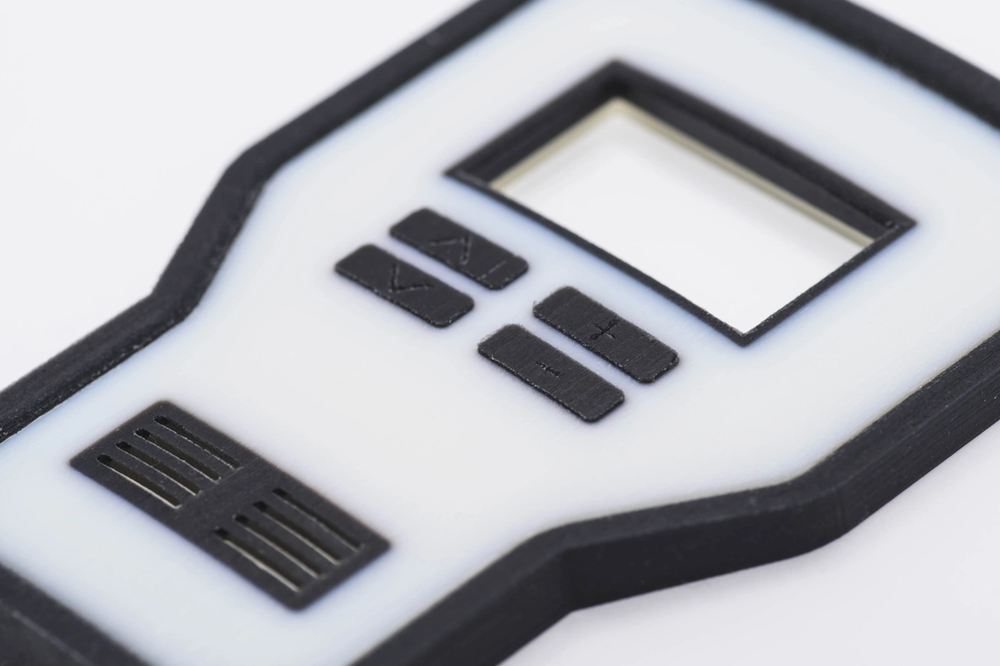

The technology also combines different materials within the same printed part. Users can produce multi-material and multi-color items in a single print volume. The process shows great promise in creating intricate components with integrated functionality. However, some limitations exist. It’s worth mentioning that high costs and UV-activated photopolymers’ tendency to become brittle over time need careful consideration when choosing this manufacturing method.

This piece covers everything in material jetting technology. Readers will learn about its basic process and real-world applications to understand its strengths and limitations in advanced manufacturing.

Understanding the Material Jetting Process

Material jetting works through a droplet deposition system that combines precision mechanics with advanced curing techniques. This technology builds objects layer by layer, which sets it apart from other manufacturing methods.

Step-by-step breakdown of how material jetting works

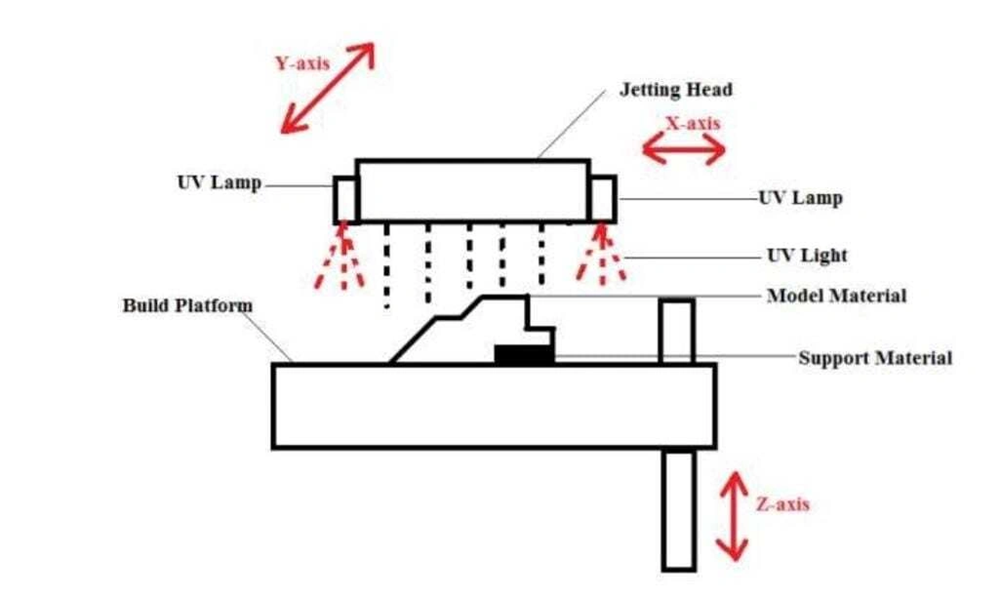

The process starts when liquid photopolymer resin heats up to temperatures between 30-60°C. This temperature range gives the resin the right thickness to print. The heated material then flows into special printheads mounted on an X-axis carriage that moves across the build platform. These printheads release hundreds of tiny resin droplets in exact patterns based on the digital model.

UV light sources attached to the carriage instantly cure the jetted material right after it lands. This creates a solid first layer. The build platform then drops down by one layer height, usually about 16 microns. This process keeps going until the object is complete. Support structures print at the same time, often using materials that dissolve during cleanup.

Photopolymerization and UV curing mechanism

The heart of material jetting lies in photopolymerization, which turns liquid resins into solid objects. UV light triggers a reaction in the photopolymer droplets. This light makes monomers and oligomers in the liquid connect and harden.

Material jetting uses UV light with wavelengths between 190-400 nm. These wavelengths differ from SLA (355 nm) and DLP (405 nm) technologies. Each layer cures fully before the next one starts. Parts made this way don’t need extra curing time like stereolithography does. The super-thin layers help achieve ideal properties right away.

Line-wise deposition vs point-wise deposition

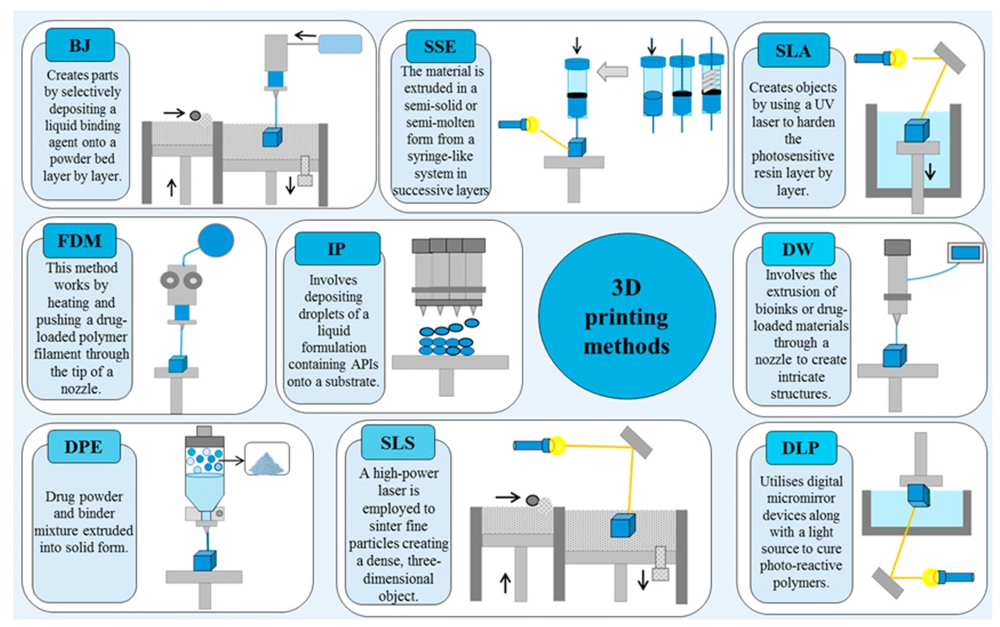

Material jetting stands out because it deposits material in lines. Other technologies like FDM, SLA, and SLS follow specific paths to build each layer. Material jetting covers the entire print surface in one go.

This approach brings big advantages. Multiple printheads can sit side by side on the same carrier and release different materials at once. This makes complex multi-material and multi-color printing straightforward. The system can also print several objects at the same time because it covers multiple pieces in a single line.

Line-wise printing combined with exact droplet control and instant curing makes material jetting one of the fastest and most accurate 3D printing methods available today.

Key Characteristics of Material Jetting Technology

Material jetting stands out among advanced additive manufacturing techniques because of its exceptional precision capabilities. The technology shines in four critical performance areas that shape its industrial applications.

Layer height and resolution: 16–32 microns

Material jetting creates remarkable detail through its layer thickness control. Layer heights typically range from 16 to 32 microns, while some systems can achieve layer thickness as fine as 13 microns. The precision comes naturally since manufacturers preset most process parameters due to droplet formation’s complex physics. Print heads deposit tiny droplets with resolutions up to 600 x 600 dpi or higher. This results in parts with exceptional surface smoothness right out of the machine.

Dimensional accuracy: ±0.1% tolerance

Material jetting systems boast some of the highest dimensional precision in additive manufacturing. These machines deliver a dimensional accuracy of ±0.1% with typical lower limits of ±0.1 mm, and can even reach ±0.02 mm. The accuracy comes in part from the relatively low build chamber temperatures (30-60°C). This minimizes residual stress, shrinkage, and deformation issues. Notwithstanding that, larger elements can see accuracy impacts from CAD software’s tessellation approach, while the rasterization process affects smaller features more.

Support structure requirements and removal methods

Material jetting needs support structures whatever the overhang angles, unlike some other additive technologies. These supports use dissolvable materials printed alongside the main object. The removal process includes:

- Manual separation for original support removal

- Water pressure systems like water jets to remove bulk support

- Chemical baths (1-2% caustic soda solution) to dissolve supports completely

- Ultrasonic baths to clean intricate features thoroughly

Proper removal leaves no marks thanks to the supports’ dissolvable nature.

Glossy vs matte surface finish options

Material jetting gives users two distinct surface finish options. Glossy mode adds support material only where structure demands it (for overhangs). This creates shiny surfaces in unsupported areas. This economical solution uses less material but produces non-uniform finishes with slightly rounded edges.

Matte finishing takes a different approach by applying a thin support layer around the entire part. The orientation doesn’t matter. Users get a uniform, non-reflective surface that’s perfect to paint, sand, or glue. While it needs more material and time to process, matte finishes reward users with sharper edges and better dimensional accuracy.

Materials Used in Material Jetting Additive Manufacturing

Material jetting uses a wide range of photopolymer resins that are created for specific applications and performance needs. These materials’ chemical makeup directly shapes their mechanical properties, transparency, flexibility, and heat resistance.

Standard rigid photopolymers

Rigid photopolymers are the foundations of material jetting applications and work best for prototypes that need dimensional stability. General-purpose materials like RGD720 provide excellent dimensional stability and smooth surfaces. DraftGrey serves as a cost-effective option that prints twice as fast while you retain control over quality for concept modeling. Advanced formulations like ToughOne deliver strength, durability, and precision for functional prototypes. Digital ABS Plus gives you high impact strength and better temperature resistance. These rigid materials can simulate injection-molded plastic parts, though they break more easily than their traditional counterparts.

Flexible and rubber-like materials

Material jetting’s flexible photopolymer options excel at applications needing elasticity. Elastico material has rubber-like properties that work perfectly for advanced design verification and rapid prototyping. TissueMatrix is the softest 3D printing material you can buy commercially. It creates models that feel like real organ tissue under pressure. The combination of TissueMatrix with Agilus30 can recreate different tissue types from highly stretchy to firm, which makes it possible to copy fatty tissue, fibrotic tissue, soft organs, and tumors. Designers can use these materials to create complex shapes with fine details.

Transparent and high-temperature resins

VeroClear handles transparency needs by mimicking acrylic as a glass alternative. High-temperature resins show remarkable heat stability – some materials can withstand temperatures up to 238°C at 0.45 MPa after proper post-curing. PMMA options like ACRYREX CM-211 flow well, stay clean, and look crystal clear. You can create clear prototypes that look like glass with these materials and polish them to achieve 100% clarity.

Medical-grade and biocompatible materials

Medical professionals benefit greatly from specialized biocompatible photopolymers. Stratasys offers MED625FLX, a flexible, see-through material that prints indirect bonding trays. MED610 produces rigid, transparent parts like surgical guides for dental implant or orthopedic procedures. VeroGlaze MED620 creates opaque rigid structures for precise dental models and try-ins. These materials meet strict safety standards and are safe for skin contact over 30 days and mucosal membrane contact up to 24 hours. MED610 and MED620 can safely touch bone and skin for up to 24 hours, which makes them valuable tools in specialized healthcare settings.

Material Jetting Advantages and Disadvantages

Material jetting’s strengths and limitations play a vital role in manufacturing applications. This additive technique brings unique advantages but also comes with notable constraints.

High-resolution, multi-material, full-color capability

Material jetting delivers exceptional precision with resolution capabilities down to 14 microns. The parts produced have surfaces that match injection molding quality. The technology creates smooth, detailed components with remarkable dimensional accuracy. Its standout feature lets users print with multiple materials at once. This gives you:

- Full-color printing with CMYKW (Cyan, Magenta, Yellow, Black, White) materials that create photo-realistic models with vivid, Pantone-accurate colors

- Combination of various material properties (rigid, flexible, transparent) within a single print

- Realistic prototypes with diverse mechanical characteristics and aesthetics

Limitations in mechanical strength and material cost

Material jetting faces several practical challenges. The parts show poor mechanical properties. They work best for non-functional prototypes rather than components that bear loads. Printed objects break easily and don’t handle temperature well compared to other manufacturing methods.

Cost remains a major drawback. Material jetting stands out as one of the priciest 3D printing technologies. Both equipment and consumables come with premium price tags. Solid mass support structures instead of lattice patterns lead to substantial material waste.

Post-processing requirements and material degradation over time

Material jetting needs specific finishing steps after printing. Support removal uses water jets, ultrasonic baths, or chemical solutions. The good news is that properly removed supports leave minimal marks on the finished surface.

The materials pose a long-term challenge. Photopolymers used in material jetting lose their mechanical properties as time passes. UV light or moisture exposure speeds up this deterioration. These changes affect the printed parts’ durability, which limits their use in permanent applications.

Conclusion: Balancing Precision with Practical Limitations

Material jetting stands out as a remarkable additive manufacturing technology that expands precision and versatility boundaries. Let’s take a closer look at how this process achieves exceptional dimensional accuracy of ±0.1% and maintains layer heights as thin as 16 microns. On top of that, it lets you combine multiple materials and colors in a single print, which sets it apart from other manufacturing methods.

This technology shines especially when you have esthetic quality and fine detail requirements. So industries like medical modeling, product design, and architectural visualization benefit substantially from its capabilities. The wide range of available materials—from rigid photopolymers to flexible elastics and biocompatible resins—opens up even more possibilities.

All the same, material jetting has important limitations you need to think about before implementation. The printed parts look impressive but tend to be brittle with limited mechanical strength compared to traditional manufacturing methods. The equipment and material costs also put this technology at the premium end of additive manufacturing options.

Material degradation over time creates another big challenge. UV-activated photopolymers lose their properties gradually, particularly when exposed to light or moisture. Projects that need long-term stability might require different solutions.

Material jetting’s future largely depends on advances in material science. New photopolymers with better mechanical properties and longevity would address the technology’s biggest weaknesses. For now, material jetting works best for prototyping, visualization models, and specialized applications where its unmatched precision and multi-material capabilities justify the cost.

In a nutshell, material jetting showcases both the impressive possibilities and current limitations of advanced additive manufacturing. It delivers extraordinary precision and esthetic quality while still working to overcome practical constraints that limit wider industrial adoption.

FAQs

Q1. What is material jetting and how does it work? Material jetting is an additive manufacturing process where droplets of liquid photopolymer are selectively deposited onto a build platform and then cured using ultraviolet light. The process builds objects layer by layer, similar to how a 2D printer works, but in three dimensions.

Q2. What are the key advantages of material jetting? Material jetting offers high-resolution printing with layer heights as low as 16 microns, multi-material and full-color capabilities, and exceptional dimensional accuracy of ±0.1%. It’s particularly useful for creating detailed prototypes and visual models.

Q3. What types of materials can be used in material jetting? Material jetting can use a variety of photopolymer resins, including rigid plastics, flexible rubber-like materials, transparent resins, and biocompatible materials for medical applications. This allows for a wide range of properties and applications.

Q4. What are the main limitations of material jetting? The primary limitations of material jetting include the high cost of equipment and materials, relatively poor mechanical properties of printed parts, and the tendency for materials to degrade over time, especially when exposed to UV light or moisture.

Q5. How does material jetting compare to other 3D printing technologies? Material jetting offers superior surface finish and detail compared to many other 3D printing methods. However, it’s generally more expensive and produces parts with lower mechanical strength. It excels in creating visual prototypes and multi-material objects but may not be ideal for functional, load-bearing components.