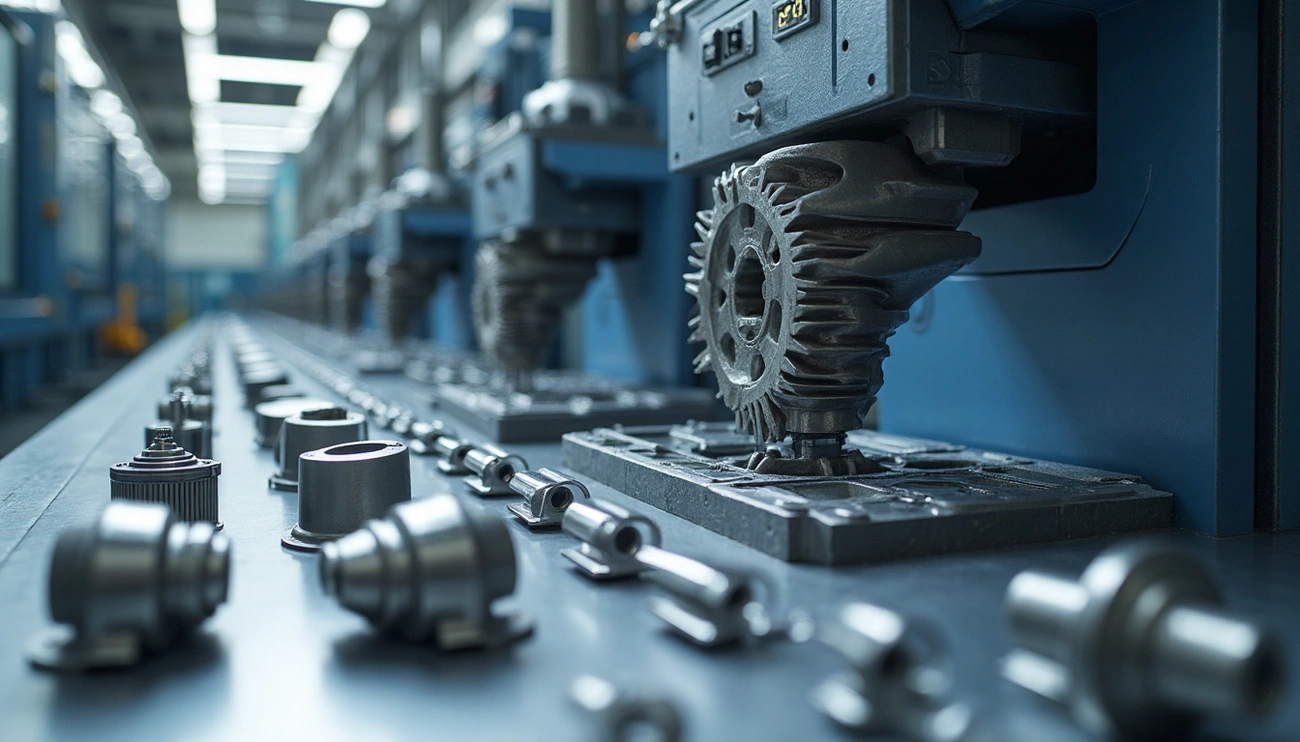

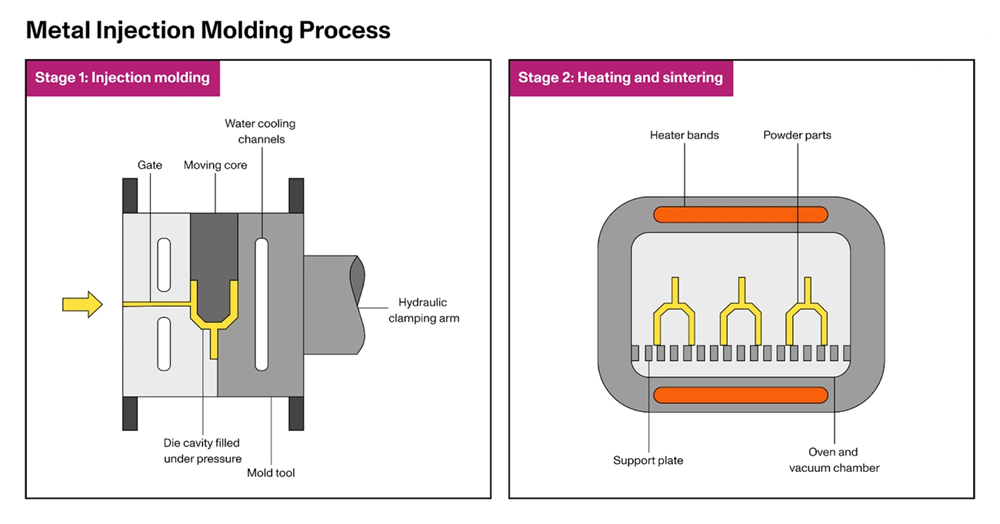

Injection molding automotive applications are reshaping vehicle manufacturing. The global automotive Metal Injection Molding market will grow at a compound annual rate of 6.5% from 2020 to 2027. This growth shows MIM technology’s rising impact in modern vehicle production. Metal injection molding merges plastic injection molding principles with powder metallurgy. Manufacturers can now create complex metal parts in high volumes with exceptional mechanical properties.

Metal injection molding offers major advantages to automotive manufacturers who need precision and efficiency. To cite an instance, MIM aids the production of safety-critical components like airbag initiators and seatbelt anchors that need exact specifications. On top of that, it helps improve fuel efficiency through lightweight components that cut down the vehicle’s overall weight. These parts match wrought materials’ mechanical properties, making them perfect for demanding vehicle applications.

MIM has become essential in automotive settings to produce intricate geometries precisely. Manufacturers can create components as single units instead of multiple assembled parts. This approach streamlines production and reduces material waste and labor costs effectively. Automotive injection molding companies help vehicle manufacturers meet strict performance requirements while staying economical in a competitive global market.

Key Advantages of Metal Injection Molding in Automotive Manufacturing

Metal injection molding stands out as a groundbreaking manufacturing technology in the automotive sector. This advanced process combines powder metallurgy with plastic injection molding techniques. The result creates precise, complex metal components that modern vehicles just need.

Design Flexibility for Complex Geometries

MIM’s remarkable design versatility serves as its main goal in automotive applications. The process excels at producing intricate, three-dimensional shapes with features that traditional metalworking methods cannot match. Engineers can design smaller, lighter components without compromising structural integrity. This becomes crucial in automotive lightweighting initiatives. MIM technology produces parts with multiple internal channels, thin walls, and complex geometries that sophisticated automotive systems require.

Material Versatility: Stainless Steel, Titanium, and More

Automotive designers gain unprecedented flexibility because MIM processes work with many materials. The options include stainless steel variants (304L, 316L, 17-4PH), low alloy steels, titanium, and specialty metals like tungsten. The process handles high-temperature steels and superalloys that get pricey to machine through traditional methods. To cite an instance, see how MIM processes Inconel 713 effectively for high-temperature applications. The technology also works with magnetic materials and electronic packaging materials that have specialized properties like low thermal expansion. This makes it perfect for both mechanical and electronic automotive components.

High-Volume Production with Minimal Waste

MIM streamlines processes in mass production scenarios effectively. The per-unit production cost drops by a lot for large-volume manufacturing, despite higher original tooling costs. Raw material wastage is reduced by about 60% compared to traditional methods. The process combines multiple components into a single integrated assembly, which saves up to 40% in costs. Near-net-shape manufacturing minimizes post-processing needs, which boosts production efficiency further.

Mechanical Strength Comparable to Wrought Metals

MIM components match the mechanical properties of parts made through conventional methods closely. Properly sintered MIM parts achieve about 98% density, like in cast components. Parts come out with uniform density and fewer defects than some traditional manufacturing techniques. 17-4 PH stainless steel processed through MIM typically shows a yield strength of 980 MPa. Dynamic properties like fatigue strength might be nowhere near as high due to residual porosity. Yet, the overall performance meets demanding automotive applications’ requirements.

Injection Molding Automotive Parts: Where MIM Excels

Modern vehicles rely heavily on MIM components that serve crucial functions in everything from powertrain to safety features. These components work perfectly for many demanding applications because injection molding automotive processes create precise and complex parts.

Engine Components: Valve Guides and Turbocharger Vanes

MIM creates essential engine parts that need precision and heat resistance. Turbocharger vanes made through MIM meet extremely tight dimensional tolerances of ±0.015 mm on wing profiles. These parts work well at temperatures up to 800–850°C, especially with heat-resistant materials like HK30 austenitic stainless steel. MIM’s unique ability creates hollow, lightweight valve guides and variable valve system components that traditional manufacturing can’t match.

Transmission Gears and Shift Levers

MIM produces precision gears and shift levers for transmission systems. Fe-2% Ni alloy makes up most manual transmission shift levers, which undergo case-hardening after sintering. Transmission components made through MIM deliver the fatigue resistance and tight tolerances needed for smooth operation. The process creates parts with uniform microstructures that work better than investment-cast products.

Fuel Injection System Components

Fuel injection systems need precise MIM components like injectors and nozzles. These parts must meet exact specifications and resist corrosion to work reliably in tough environments. MIM creates complex, compact components that help improve vehicle fuel efficiency. Fuel pump and injector system parts benefit from combining multiple components into single assemblies, which cuts costs by 65% compared to older manufacturing methods.

Safety Parts: Airbag Initiators and Seatbelt Anchors

Safety systems use many MIM components where reliability matters most. MIM-manufactured airbag initiators provide consistent performance during emergencies. Seatbelt anchors also benefit from MIM’s precision and strength. These critical safety components meet strict industry standards thanks to MIM’s ability to create complex shapes with high strength.

Interior Accessories: Door Handles and Trim

MIM components show up throughout vehicle interiors in door handles, mirror mounts, and decorative trim. Interior rotary control wheels made from 316L stainless steel last four times longer than electroplated plastic options. These parts enhance the vehicle’s quality, particularly in looks and feel.

Electrical Connectors for Vehicle Electronics

Electronics dominate modern vehicles, making reliable electrical connectors crucial. MIM creates intricate connectors that maintain stable connections throughout the electrical systems. These parts stand up to vibration, temperature changes, and environmental exposure while delivering consistent electrical performance—making MIM the perfect manufacturing choice.

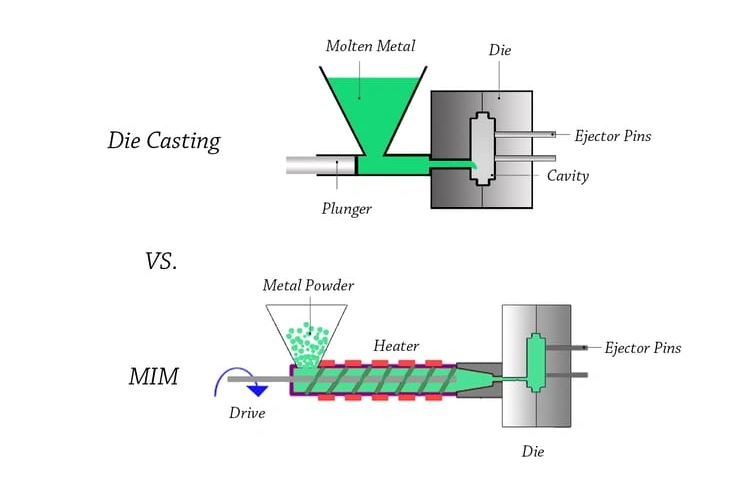

Metal Injection Molding vs Die Casting in Automotive Applications

The choice between metal injection molding vs die casting affects part quality, cost, and performance in automotive applications. These processes create precise metal components. Their capabilities and limitations differ by a lot.

Precision in Small, Intricate Parts

MIM excels at producing small, complex components with fine features under 2 mm that die casting cannot manufacture. Die casting handles both smaller (30g) and very large products (over 10kg), while MIM works best with parts weighing 15-20g. Parts over 50g become difficult to make with MIM because of machine limitations. MIM creates more accurate dimensions with tight tolerances. Die cast parts need trimming to meet specifications.

Tooling Lifespan and Cost Comparison

Die casting molds last longer and produce up to one million parts before replacement. MIM molds typically produce between 150,000-300,000 shots. The die casting tooling costs range from $1,200-$4,200, while MIM tooling costs fall between $1,400-$2,800. MIM’s process costs run higher than die casting, making die casting potentially 30% cheaper depending on use.

Shrinkage and Dimensional Accuracy Differences

Material shrinkage during manufacturing marks a key difference between these processes. MIM parts shrink by 15-20% during sintering. Die casting shows minimal shrinkage at about 0.001 per mm. Manufacturers must factor this substantial difference into their MIM designs. Both processes can achieve a dimensional accuracy of ±0.05 mm.

Material Compatibility and Temperature Requirements

Material options create another key distinction. MIM works with both ferrous and non-ferrous metals, including stainless steel and titanium alloys. Die casting works best with non-ferrous metals like aluminum, zinc, and magnesium. Temperature control plays a crucial role. Die casting requires careful monitoring to prevent die damage from overheated metal or defects from rapid cooling. The die temperature should stay at about one-third of the alloy’s temperature.

Role of Automotive Injection Molding Companies in Scaling MIM

Vehicle manufacturers rely heavily on automotive injection molding companies when they adopt MIM technology. These specialized firms connect design concepts with adaptable manufacturing solutions. They help OEMs guide through the complexities of metal injection molding implementation.

Design Optimization Support for Automotive OEMs

Automotive OEMs benefit from specialized MIM manufacturers’ design for manufacturing (DFM) expertise. Engineers from these firms work together to optimize part designs for the metal injection molding process. Their consultation gives guidance on vital design features like wall thickness, draft angles, tolerances, and other elements. These features ensure manufacturability and maintain performance. The companies analyze designs and find opportunities for part consolidation. This approach has cut manufacturing steps by about 40% in some applications. Automotive injection molding companies help vehicle manufacturers spend less time in development while getting the most out of component functionality.

Material Selection Consulting for Performance Goals

Material expertise stands out as a vital service from injection molding automotive partners. These specialists help you choose from MIM’s wide material portfolio of stainless steels, low alloy steels, and specialty metals. Metallurgical experts can even create custom alloy formulations that meet specific performance needs. They adjust compositions to achieve targeted properties like high strength, wear resistance, and corrosion protection. The team bases their selection on functional and technical requirements. They factor in performance goals, cost limits, and environmental impact.

End-to-End Manufacturing from Prototyping to Mass Production

The complete manufacturing support throughout the product lifecycle adds exceptional value. MIM companies create functional prototypes through metal 3D printing to test fit, form, and function. They can produce injection mold tooling in just two weeks after validation, which speeds up time-to-market substantially. Multiple-cavity tooling with automation capabilities enables high-volume manufacturing for full-scale production.

H MIM brings nearly 20 years of expertise in metal injection molding and powder metallurgy. Their facilities span more than 18,000 square meters. World-class equipment and 150 skilled workers deliver precision-engineered products to customers worldwide. Quality control remains strict with state-of-the-art monitoring systems and statistical process control. This ensures that parts consistently meet the demanding specifications of automotive applications.

Conclusion

Conclusion: The Future of Metal Injection Molding in Automotive Manufacturing

Metal injection molding technology is changing automotive manufacturing by giving unmatched advantages in producing complex, high-performance components. The automotive industry gets substantial benefits from MIM’s exceptional design flexibility. This technology helps create intricate geometries that weren’t possible with conventional manufacturing methods. The wide range of compatible materials—from stainless steel to titanium alloys—gives automotive engineers more options to optimize component performance.

The economic advantages are clear. MIM processes cut material waste by about 60% compared to traditional methods. Part consolidation can lower costs by up to 40%. These savings help vehicle manufacturers who need to reduce weight, improve fuel efficiency, and keep prices competitive.

When compared to die casting, MIM shows superior capabilities for small, complex parts with exceptional dimensional accuracy. Die casting works better for larger components, but MIM excels in precision and material properties.

Success with MIM depends on experienced manufacturers. H MIM brings nearly 20 years of experience in metal injection molding and powder metallurgy. Their facilities span more than 18,000 square meters with world-class equipment. The company’s 150 skilled workers deliver precision-engineered products to customers worldwide.

Automotive designs are becoming more complex and performance needs are growing. Without doubt, metal injection molding will expand its presence throughout vehicle systems. The technology combines design freedom, material options, and production efficiency. This makes it essential for next-generation automotive components. Companies that become skilled at MIM implementation gain a competitive edge where precision, performance, and budget-friendly solutions determine success.

FAQs

Q1. What are the key advantages of metal injection molding in automotive manufacturing? Metal injection molding offers design flexibility for complex geometries, material versatility, high-volume production with minimal waste, and mechanical strength comparable to wrought metals. It allows for the creation of intricate parts with fine features and tight tolerances, making it ideal for various automotive components.

Q2. How does metal injection molding compare to die casting for automotive applications? Metal injection molding excels in producing small, complex parts with high precision, while die casting is better suited for larger components. MIM offers greater material options and tighter tolerances but experiences more shrinkage. Die casting generally has lower process costs and longer-lasting molds, making it more cost-effective for certain applications.

Q3. What types of automotive parts are commonly produced using metal injection molding? Metal injection molding is used to create various automotive components, including engine parts like valve guides and turbocharger vanes, transmission gears, fuel injection system components, safety parts such as airbag initiators and seatbelt anchors, interior accessories, and electrical connectors for vehicle electronics.

Q4. How do automotive injection molding companies support manufacturers in implementing MIM technology? Automotive injection molding companies provide design optimization support, material selection consulting, and end-to-end manufacturing services. They assist in optimizing part designs for the MIM process, help select appropriate materials for specific performance goals, and offer comprehensive production support from prototyping to mass production.

Q5. What is the future outlook for metal injection molding in the automotive industry? The future of metal injection molding in automotive manufacturing looks promising. As vehicle designs become more complex and performance requirements increase, MIM is expected to expand its presence throughout vehicle systems. Its unique combination of design freedom, material options, and production efficiency positions it as an essential manufacturing process for next-generation automotive components.