What Are Powder Metallurgy Parts? The Manufacturing Process and Applications of Powder Metallurgy Components

Powder metallurgy parts are innovative engineering components that play a crucial role in various industries, including automotive, aerospace, medical, and consumer electronics.

What powder metallurgy parts are?

How they are manufactured?

Advantages of powder metallurgy

Applications powder metallurgy

What Are Powder Metallurgy Parts?

Powder metallurgy, commonly referred to as PM, is a manufacturing process for creating components from metal powders. These powders are meticulously selected, mixed, and compacted into the desired shape before being sintered, ultimately forming solid, dense, and intricately designed parts. Powder metallurgy parts are renowned for their exceptional precision, versatility, and cost-effectiveness.

How About Powder Metallurgy Process

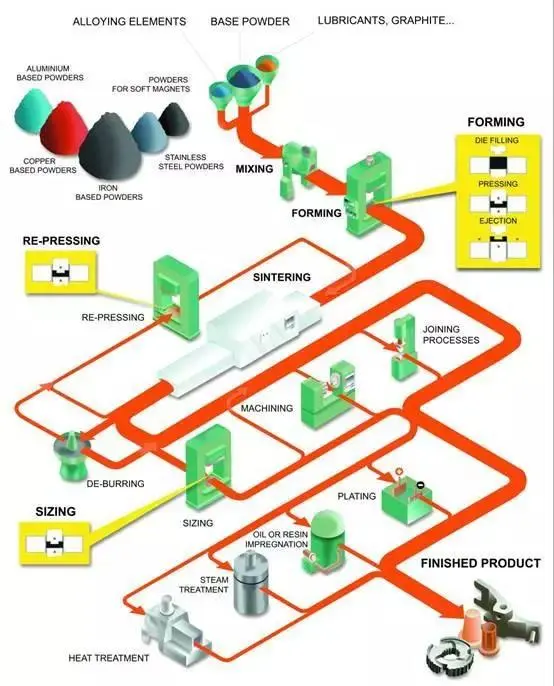

Manufacturing powder metallurgy parts involves several crucial steps:

- Powder Selection: High-quality metal powders are chosen to meet specific material and performance requirements. This can include ferrous and non-ferrous materials such as iron, copper, stainless steel, and more.

- Powder Blending: The selected powders are blended, sometimes with the addition of lubricants and binders, to ensure proper flowability and formability.

- Compaction: The blended powder is compressed into the desired shape using various methods such as pressing, injection molding, or extrusion.

- Sintering: The compacted parts undergo high-temperature sintering, a process where the metal particles bond and form a solid piece with improved mechanical properties.

- Finishing Operations: Secondary operations like machining, heat treatment, and surface treatment may be applied to achieve precise dimensions and enhanced characteristics.

Advantages of Powder Metallurgy Parts:

- Complex Geometries: Powder metallurgy allows the creation of intricate shapes and structures that would be difficult or costly to achieve through traditional manufacturing methods.

- Cost-Effectiveness: This method minimizes material waste, resulting in reduced raw material costs. Additionally, the process eliminates the need for extensive machining, reducing labor costs.

- High Precision: Powder metallurgy provides tight tolerances, excellent surface finish, and dimensional stability.

- Material Variety: The process supports a wide range of materials, enabling the production of parts with diverse mechanical and thermal properties.

- Consistency: Powder metallurgy ensures consistent quality, as the same parts can be replicated with minimal variation.

Applications of Powder Metallurgy Parts:

Powder metallurgy parts find applications across multiple industries:

- Automotive: PM components are used in engines, transmissions, and chassis to reduce weight and improve fuel efficiency.

- Aerospace: The aerospace industry employs powder metallurgy parts for their lightweight and high-strength properties in aircraft components.

- Medical Devices: Surgical instruments, dental appliances, and medical implants benefit from the biocompatibility and corrosion resistance of PM materials.

- Electronics: PM components are crucial in electronics, such as electrical contacts and magnetic cores, due to their precision and magnetic properties.

- Industrial Tools: Powder metallurgy parts are found in cutting tools, gears, and bearings, where durability and wear resistance are essential.

Conclusion:

Powder metallurgy parts are a remarkable advancement in manufacturing technology. Their ability to deliver cost-effective, high-precision, and versatile components has solidified their place in a wide range of industries. Understanding the powder metallurgy process and the advantages it offers can help businesses make informed decisions when seeking efficient, high-quality engineering solutions.

The Essence of Powder Metallurgy Parts Design

Introduction:

In the ever-evolving fields of engineering and manufacturing, the role of powder metallurgy parts design has gained increasing prominence. This article delves into the intricate world of designing powder metallurgy parts, exploring the principles, processes, and innovative techniques that drive this fascinating field forward.

Understanding Powder Metallurgy Parts Design:

Powder metallurgy parts design is an essential aspect of creating components with precision and efficiency. It involves a comprehensive approach that starts with a clear understanding of the desired performance and material requirements. To master this art, several key principles should be considered:

- Material Selection: The foundation of any powder metallurgy design is selecting the right material. It’s crucial to evaluate the properties and characteristics of available powders to meet the specific needs of the application.

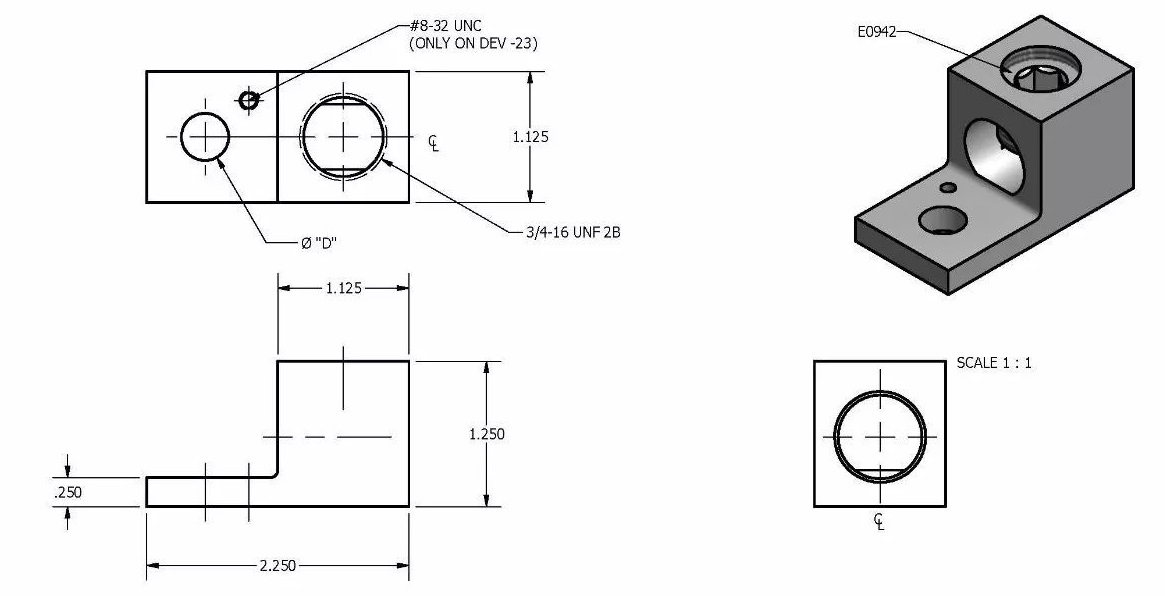

- Complex Geometries: One of the distinct advantages of powder metallurgy is the ability to create complex shapes and intricate geometries. Designers can leverage this capability to optimize performance and functionality.

- Dimensional Accuracy: Achieving tight tolerances and dimensional accuracy is a hallmark of successful powder metallurgy part design. This is vital, especially when the parts need to fit precisely with other components.

- Part Consolidation: The design process should consider part consolidation – combining multiple components into a single powder metallurgy part, reducing assembly complexity and costs.

The Design Process:

The process of designing powder metallurgy parts involves the following steps:

- Conceptualization: This phase involves defining the component’s purpose, material selection, and preliminary design sketches. It’s crucial to set clear objectives and performance targets.

- Modeling and Simulation: Utilizing advanced software, engineers create detailed 3D models and simulate the performance of the part under different conditions. This step aids in optimizing the design for functionality and cost-effectiveness.

- Tooling Design: Tooling, such as molds and dies, plays a critical role in the manufacturing process. Designing the right tooling is crucial to ensure consistency and quality in production.

- Material Preparation: Selecting and preparing the appropriate metal powders, binders, and lubricants are essential aspects of the design process. The materials are mixed and blended to achieve the desired composition.

- Compaction and Sintering: The compacting process shapes the material, followed by high-temperature sintering, where the part is formed. Understanding the impact of these steps on the final part’s properties is vital for successful design.

Innovations in Powder Metallurgy Design:

The field of powder metallurgy parts design is not stagnant. Engineers are constantly exploring innovative techniques to push the boundaries of what’s possible. This includes advancements in materials, digital design tools, and sustainability practices. Additionally, the integration of additive manufacturing (3D printing) with powder metallurgy has opened new avenues for creative and efficient designs.

Conclusion:

Designing powder metallurgy parts is a dynamic and creative process that bridges the gap between engineering, materials science, and manufacturing. Successful designs result in components that offer precision, cost-effectiveness, and durability across a wide range of industries. As technology continues to advance, so will the art of powder metallurgy part design, driving innovation and progress in countless applications.

Custom Powder Metallurgy Parts

“JH MIM has outstanding technological advantages in the field of powder metallurgy in our factory. Our professional team is proficient in advanced powder preparation, shaping, and sintering technologies, as well as the latest automation production equipment. This not only enables us to produce high-quality powder metallurgy products but also to provide personalized customized solutions to meet various needs.

Quality has always been the core value of our factory. We have established strict quality control and inspection procedures to ensure product consistency and reliability, in compliance with international standards and customer expectations. Whether in the selection of raw materials or the production process, we strive for excellence in quality standards.

We are dedicated not only to providing high-quality products but also to customer service. Our team is always ready to provide timely technical support and excellent after-sales service. We understand customer needs, strive to meet their expectations, and have built long-term partnerships.

Our factory actively pursues sustainable development. We implement environmental measures, optimize resource utilization efficiency, and fulfill social responsibilities. Our proud products have been widely applied in various fields and have achieved excellent performance.

If you are looking for a reliable partner in the field of powder metallurgy, we encourage you to consider collaborating with our factory. We look forward to establishing a successful partnership with you and achieving excellence and success together.”