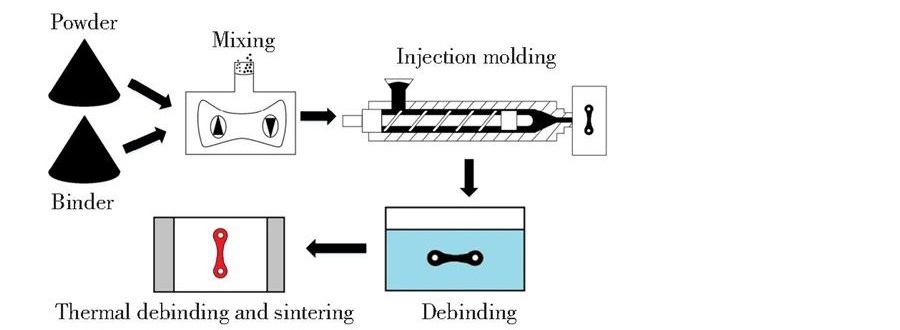

Metal injection molding (MIM) is a molding processing method that injects a plasticized mixture obtained by mixing a binder and metal powder into a specific mold. It is a method developed by combining powder metallurgy and polymer injection molding. New molding technology. It is particularly suitable for the mass production of small, complex-shaped metal products with large quantities, especially precision metal parts with complex structures, small volumes, and special requirements that are difficult to process with traditional processing methods and have high processing costs. Metal powder injection molding can Reduce processing costs.

The production process of metal powder injection molding (MIM) products is: powder + binder mixing, granulation, injection molding, degreasing (MIM degreasing furnace), sintering (MIM sintering furnace), and subsequent processing to form the product. In the process of producing MIM cemented carbide parts, improper material selection and operation control in any link may cause defects in the cemented carbide parts.

So how to avoid such defects?

1. Powder selection link. In addition to meeting its basic requirements such as particle size distribution and particle size, MIM cemented carbide powder metallurgy also requires high purity of the powder. Powder containing impurities cannot be used. If the powder contains elements such as sulfur, phosphorus, and silicon, During the sintering process, these substances will form pores and cause product defects.

2. Feeding production process. Carbide powder requires a suitable binder when mixing. When mixing, the cemented carbide powder and the binder are fully mixed. The temperature must be strictly controlled during the mixing process to avoid volatilization and uneven distribution of the binder. The situation allows the mixed material to have good rheological properties and viscosity values after being fed, so as to avoid defects in subsequent links.

3. The stage of forming the green body. This is also a key link in the production of cemented carbide parts. To avoid product defects, attention needs to be paid to reasonably controlling the temperature of the mold, the amount of material added, the injection pressure, the holding pressure, the holding time, the injection speed, etc. during the injection process, which can effectively Avoid defects in the injection green body.

4. Degreasing link. During the degreasing process of cemented carbide green bodies, if the degreasing furnace heats up too quickly, it will cause cracks and defects in the cemented carbide parts. The step-by-step heating method can be used for degreasing.

5. Sintering link. The density of cemented carbide is high, and the product is prone to deformation due to its own gravity during liquid phase sintering. Appropriate support devices can be used. For larger products, materials with comparable shrinkage rates can be selected as support plates. In addition, the liquid phase sintering time should be shortened as much as possible.

Common defects of metal powder injection molded parts are as follows.

- Under-injection: Under-injection refers to the failure of the material to fill the entire mold cavity due to factors such as insufficient pressure of the injection molding machine or poor fluidity of the injection material used, resulting in incomplete injection products. The reasons for insufficient injection are poor material fluidity, product wall thickness is too small, mold temperature is too low and injection time is too short. Corresponding measures can be taken to improve material fluidity or replace materials, increase wall thickness, increase mold temperature, increase injection pressure and Measures such as extending the injection time can be solved.

- Weld marks: During the injection process, the material is divided into several streams in the mold cavity and then merged together. Linear marks may appear at the junction, which are weld marks, which affect the appearance quality and even mechanical strength of the product. The reasons for the formation of weld marks are that the injection pressure is too low, the injection speed is too slow, the material temperature and mold temperature are too low, and the number of material flow strands is too large. Corresponding measures can be taken to increase the injection pressure, speed up the injection speed, increase the material temperature, and reduce the mold temperature appropriately. diversion and other measures to solve the problem.

- Air pockets. During the injection process, the air in the mold cavity has no time to be discharged, and is trapped by the material or compressed to the inner wall of the mold to form air pockets, causing under-injection on the surface of the product and affecting the appearance quality and even mechanical strength of the product. The causes of air pockets are poor exhaust, inappropriate gate position, too fast injection speed, and excessive changes in product thickness. You can add or deepen the exhaust holes, change the gate position, and slow down the injection appropriately. Speed, extend the holding time and avoid rapid changes in product thickness.

- Deformation. Deformation refers to the bending or distortion of the molded product after cooling, which directly affects the appearance and dimensional accuracy of the product, and even causes the product to be scrapped. The causes of deformation are uneven cooling of the product, too hot and premature ejection of the product, too thin product and unreasonable structure and residual stress inside the product. Corresponding measures can be taken to evenly cool the mold water channel, extend the holding time and timely eject the product to improve the product. Measures such as wall thickness and structural design and improving molding conditions can be solved.

Metal injection molding (MIM) can form complex-shaped cemented carbide products. With the problem of defect control solved and the gradual improvement of MIM technology, the application scope of cemented carbide has gradually expanded, greatly promoting the development of the entire cemented carbide industry. develop.