Gear Manufacturing

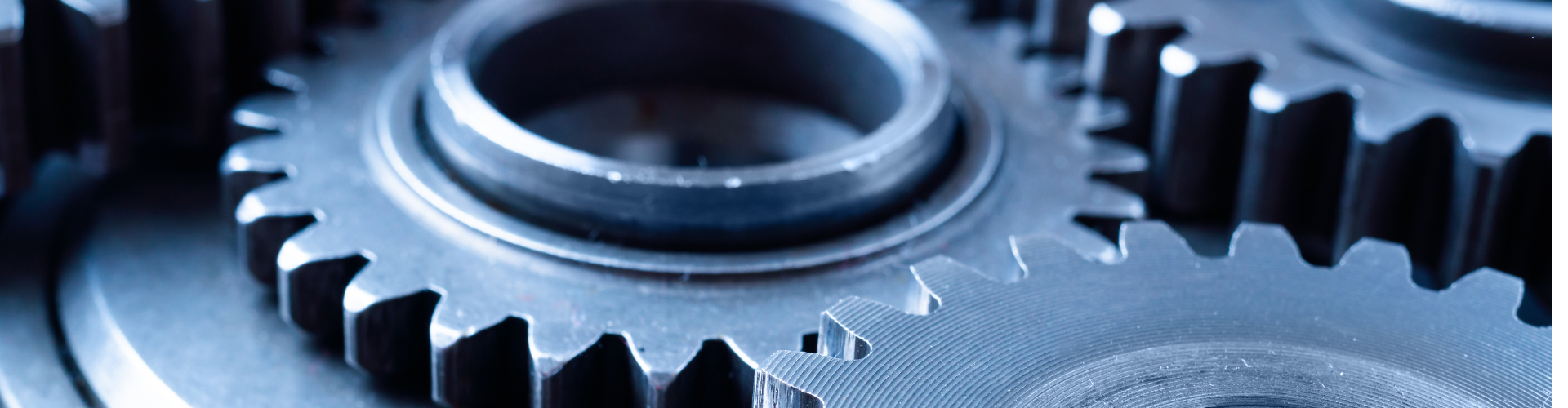

Gear is a common mechanical transmission component, usually consisting of a number of wheels with teeth. They realize the purpose of rotation and power transmission through meshing.

A gear is generally composed of two or more disks, at least one of which has teeth on it. The gear transmits power and rotates through the meshing motion between teeth. In the meshing process, when the big gear drives the small gear to rotate, the speed of the output shaft can be reduced, and the output torque can be increased. On the contrary, the speed of the output shaft can be increased, but the output torque is reduced.

Gears are widely used in various mechanical equipment, such as automobiles, aircraft, industrial machines, electronic equipment and so on. They are designed as reliable drivetrains for precise control of output speed and torque, while also being able to deliver large amounts of power.

Powder metallurgy Gear Manufacturing Processes

Powder metallurgy gear production is the process of making gear with powder metallurgy technology. The main advantage of this process is that it can produce gears of complex shapes with the advantages of high strength, low noise, low friction and low cost.

The production process of powder metallurgy gear consists of the following steps:

- Raw material preparation: Mix the metal powder in a certain proportion, and add some additives (such as lubricant) to improve its fluidity and compactability.

- Mold manufacturing: Manufacture a mold with the same shape as the gear.

- Pressing: Put the mixed metal powder into the mold, and compress it into a blank body with certain strength through high pressure.

- Sintering: Put the billet into the heat treatment furnace, so that it sintered into a solid gear at high temperature.

- Processing: necessary processing of gear, such as tooth surface dressing, hole processing, etc.

- Surface treatment: gear surface treatment, such as chrome plating, spraying, etc.

The above are the basic steps of powder metallurgy gear production. Different manufacturers may make certain improvements and innovations according to their own processes and needs.

Gears can be classified according to different classification criteria. Here are some common ways to classify gears:

- According to the purpose of gear classification: mainly can be divided into transmission gear and change gear.

- Structure of gear classification: mainly can be divided into cylindrical gear, bevel gear, worm, worm gear, etc.

- Transmission mode of gear classification: mainly can be divided into direct transmission gear, indirect transmission gear, planetary transmission gear and so on.

- Gear tooth shape classification: mainly can be divided into spur gear, helical gear, involute gear, curve gear and so on.

- Machining accuracy of gear classification: mainly can be divided into ordinary gear and precision gear.

- Material classification of gear: mainly can be divided into metal gear, plastic gear, ceramic gear, composite gear and so on.

Gear Manufacturing Materials

There are many kinds of powder metallurgy gear materials, commonly used include:

Ferrous alloys: such as ferritic stainless steel, high speed steel, etc.

Steel base alloy: such as low alloy steel, high alloy steel, etc.

Copper base alloy: such as bronze, phosphor bronze, aluminum bronze, etc.

Nickel base alloy: such as nickel base alloy 718, 625, etc.

Titanium base alloy: such as TC4 (Ti-6Al-4V), etc.

Aluminum base alloy: such as Al-Si alloy, etc.

Carbon-based alloys: such as hard alloys.

According to the application environment and performance requirements, different powder metallurgy gear materials can obtain better performance and life.

JH MIM gear manufacturing companies

Have the following conditions:

Advanced processing equipment and technology: For different types and specifications of gear, JH MIM has advanced CNC machine tools, heat treatment equipment, surface treatment equipment, etc.

Excellent technical personnel: Gear manufacturing is a work with high technical content. JH MIM has a high-quality technical team, which can independently complete gear design, process planning, processing and manufacturing.

Quality management system: Gear is an indispensable part of mechanical transmission system, its quality directly affects the performance and life of the whole mechanical system. JH MIM quality management system implements strict quality control to ensure stable and reliable product quality.

Perfect after-sales service: JH MIM provides perfect after-sales service, including installation and commissioning, maintenance, technical consultation, etc., timely solve customers’ problems, to ensure that customers’ interests are protected.

Whether small metal gear, or complex gear, JH MIM will provide you with a solution.

Tags Metal Injection Molding | MIM Materials | Design