Vacuum sintering furnaces play a crucial role in manufacturing industries where precise heating makes all the difference. The sintering process heats materials to specific temperatures – not hot enough to melt them but just right to make particles stick together. This creates solid masses with properties that manufacturers need. You’ll find these components in everything from car parts to medical devices.

Vacuum sintering furnaces play a crucial role in manufacturing industries where precise heating makes all the difference. The sintering process heats materials to specific temperatures – not hot enough to melt them but just right to make particles stick together. This creates solid masses with properties that manufacturers need. You’ll find these components in everything from car parts to medical devices.

The process works best at temperatures between 1200°C and 3000°C, and manufacturers can pick from several vacuum sintering methods based on what they need. High temperature vacuum sintering furnaces give amazing control over atmospheric conditions. High vacuum sintering furnaces get rid of any unwanted gasses that could harm the material. On top of that, vacuum hot press sintering furnaces combine heat and pressure to make the final product as dense as possible.

These advanced heating systems are the backbone of many industries. Tool manufacturers, powdered metal parts makers, advanced ceramics companies, armor producers, and aerospace firms all depend on them. Modern sintering equipment’s precise temperature control and atmospheric manipulation benefit each sector differently. Manufacturers can choose from more than a dozen sintering methods to match their material needs perfectly.

Vacuum, hot press, spark plasma, microwave, and pressure variants make up the core types of sintering furnaces. But picking the right system isn’t just about finding the “best” furnace – it’s about matching the heating method and atmospheric control to your materials, density requirements, and production targets. This piece breaks down the seven most common vacuum sintering furnace types to help you make the right choice for your manufacturing process.

Vacuum Resistance Sintering Furnace

Vacuum resistance sintering furnaces are the foundations of modern material processing systems. Quality production depends on controlled atmospheric conditions. These furnaces work at temperatures between 1100°C and 2000°C. Some specialized models can reach up to 2400°C or even 3000°C based on material needs.

Key Features of Vacuum Resistance Sintering Furnace

The unique design of vacuum resistance furnaces combines several vital components that work together to create perfect sintering conditions:

- Vacuum Chamber: The sealed environment where sintering occurs, typically constructed with water-cooled walls

- Heating Elements: Mainly tungsten mesh or graphite components that generate the required heat

- Vacuum Pumps: Systems that create and maintain vacuum levels typically reaching 6.7×10⁻³ Pa

- Loading System: Either manual or automated mechanisms for material handling

- Temperature Control: Digital intelligent systems that follow predefined temperature curves

- Water Cooling System: Circulation mechanisms that prevent overheating

The vertical structure is common in most vacuum resistance furnaces. This design works well with tungsten mesh heating elements and allows ultra-high temperature capabilities in controlled environments.

Best Applications for Vacuum Resistance Sintering Furnace

Materials needing exceptional purity work best with vacuum resistance furnaces. These include:

- Cemented carbide and hard alloys – Components needing high density and strength

- Ceramic materials – Especially high-purity ceramics for transparent applications

- Magnetic materials – Including rare-earth magnets

- Refractory metals – Particularly tungsten, molybdenum, and tungsten-copper alloys

These furnaces are a great way to get results when melting and sintering high-melting-point metals. They excel at brightening and degassing certain metals, and measuring physical and chemical properties under extreme conditions.

Advantages of Vacuum Resistance Sintering Furnace

Vacuum resistance sintering provides many benefits that make it essential for critical applications:

- Superior Material Purity: Removes oxide films completely before the liquid phase appears

- Boosted Density: Removes gases from pores and creates stronger components

- Excellent Surface Quality: Stops oxidation and decarburization, keeping a superior finish

- Improved Mechanical Properties: Creates a more uniform material structure with better hardness, strength, and toughness

- Precise Process Control: Allows exact temperature control throughout the sintering cycle

Limitations of the Vacuum Resistance Sintering Furnace

Vacuum resistance furnaces come with several challenges:

- High Equipment Cost: Complex manufacturing needs and supporting facilities increase the original investment

- Energy Intensity: High temperatures and vacuum conditions need lots of power

- Operator Expertise Required: Running these machines requires special knowledge in vacuum technology and heat treatment

- Material Restrictions: Elements with high saturated vapor pressure, like chromium, copper, and aluminum, may evaporate during processing

- Maintenance Complexity: Repairs need specialized technicians and equipment, leading to longer downtime

Vacuum Resistance Sintering Furnace Pricing

Vacuum resistance sintering furnaces’ prices vary based on specifications. Basic systems start at $55,000, while advanced models cost more than $200,000. Price differences come from:

- Maximum temperature capability

- Chamber size and heating zone dimensions

- Vacuum level achievable

- Control system sophistication

- Loading capacity (ranging from 200kg to 2000kg)

Ideal Use Cases for Vacuum Resistance Sintering Furnace

These specific applications show the true value of vacuum resistance furnaces:

- Medical Implants: Gives biocompatibility through better product purity

- Aerospace Components: Makes high-strength, lightweight parts that resist extreme temperatures

- Automotive Critical Parts: Creates components with excellent wear and corrosion resistance

- Scientific Research: Makes precise material studies under controlled conditions easier

- Hard Alloy Production: Helps manufacture cutting tools and wear-resistant components

Industries where material integrity affects product performance or safety find these furnaces worth the investment despite higher upfront costs.

Vacuum Induction Sintering Furnace

Electromagnetic induction technology works with vacuum conditions to create a powerful system for specialized sintering applications. These furnaces use alternating currents through water-cooled copper coils. The coils generate magnetic fields that induce eddy currents within conductive materials, which produce rapid and uniform heating throughout the charge.

Key Features of Vthe acuum Induction Sintering Furnace

These furnaces stand out from other sintering systems with several unique features:

- Electromagnetic Heating Mechanism: Copper induction coils generate magnetic fields that heat the metal charge directly without physical contact

- Rapid Temperature Generation: Materials heat up quickly to sintering temperatures, reaching up to 2000°C

- Sealed Vacuum Chamber: The structure has double walls made of carbon steel and stainless steel with water cooling systems

- Advanced Control Systems: The system integrates PLC and industrial computers for precise process management

- Multi-zone Temperature Control: Multiple thermocouples and infrared equipment work together to ensure even heating

- Specialized Vacuum Systems: The system uses pumps and gages to maintain exact negative pressure during sintering

These furnaces blend sophisticated thermal management with automation features. You can save and repeat programmed sintering cycles with remarkable consistency.

Best Applications for Vacuum Induction Sintering Furnace

The exceptional purity and control these systems provide make them valuable for:

- Working with reactive metals (titanium, zirconium, niobium) that oxidize easily

- Making superalloys for jet engines and nuclear reactors

- Creating specialized magnetic materials with exact properties

- Working with rare earth metals while minimizing material loss

- Making high-performance metal powders for additive manufacturing

Advantages of the Vacuum Induction Sintering Furnace

This technology offers many benefits compared to conventional methods:

- Superior Material Purity: The vacuum environment keeps out contamination from oxygen and other gases

- Homogeneous Material Structure: Direct heating ensures even melting and consistent material properties

- Precise Compositional Control: The controlled atmosphere helps manage material chemistry exactly

- Energy Efficiency: Direct heating transfers energy better than indirect methods

- Rapid Processing: Heating and cooling happen faster than with resistance heating methods

- Enhanced Temperature Control: The vacuum helps maintain uniform temperature throughout the charge

Limitations of the Vacuum Induction Sintering Furnace

Despite that, these advanced systems come with several challenges:

- High Original Investment: Complex manufacturing and support facilities drive up costs [6]

- Operating Expertise Required: The core team needs special knowledge in vacuum technology, metallurgy, and electrical systems

- Material Restrictions: Not all materials work well, especially those with high vapor pressure elements that might evaporate during processing

- Maintenance Complexity: Repairs need specialized technicians and equipment, which can lead to long downtimes

- Energy Requirements: This is a big deal, as it means that power demands are high, even with efficiency advantages

Vacuum Induction Sintering Furnace Pricing

Costs vary based on specifications and capabilities:

- Laboratory-scale units start at $70,000

- Industrial systems for aerospace or medical manufacturing can cost over $1 million

- Mid-range production models usually cost between $200,000-$500,000

Chamber size, maximum temperature capability, vacuum levels, control system sophistication, and extra features like debinding or specialized loading systems affect the price.

Ideal Use Cases for Vacuum Induction Sintering Furnace

These furnaces excel in specific applications:

- Aerospace Manufacturing: They make turbine blades, compressor disks, and engine components from nickel-based superalloys

- Medical Device Production: They create biocompatible implants and surgical tools from titanium and cobalt-chrome alloys

- Specialty Metals Production: They manufacture high-performance magnetic materials for electronics and energy applications

- Research and Development: Material experiments that need precise control over sintering parameters

- Automotive Performance Components: They produce specialized high-strength parts for demanding applications

These applications need exceptional material integrity and performance. The investment in vacuum induction technology pays off through better product quality and reliability.

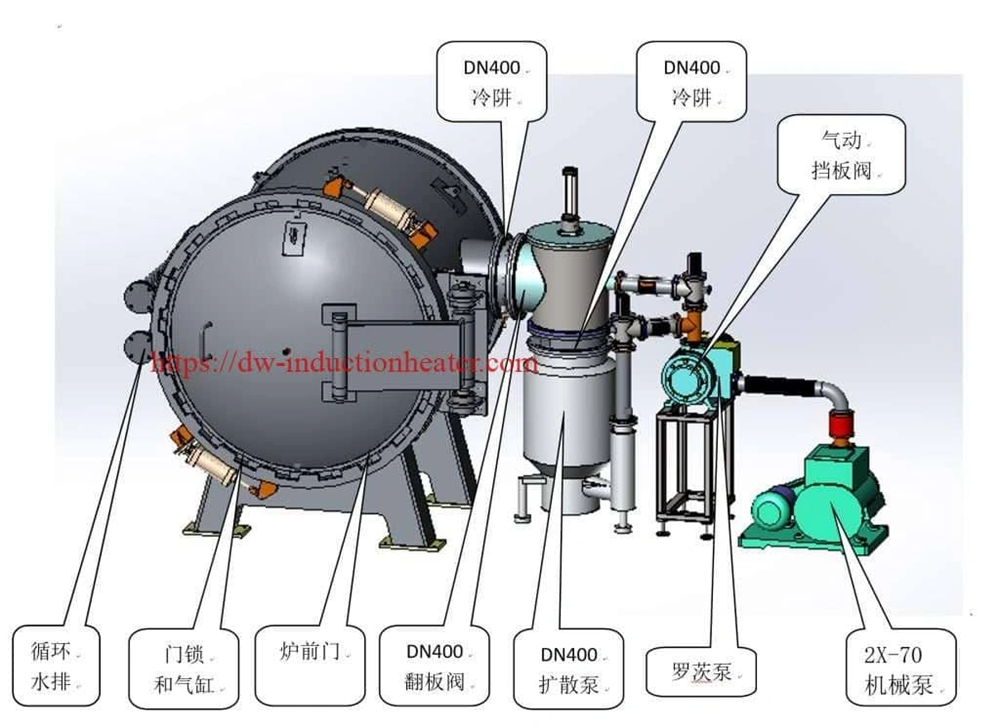

Vacuum Hot Press Sintering Furnace

Vacuum hot press sintering furnaces stand out from regular sintering technologies because they use heat and pressure at the same time. These furnaces create advanced materials by combining intense heat with mechanical force in an oxygen-free environment. The result is components with exceptional density and material integrity. Manufacturers can achieve properties that heat treatment alone cannot deliver through this controlled process.

Key Features of Vacuum Hot Press Sintering Furnace

These furnaces combine several critical components that work smoothly together:

- Vacuum Chamber and Pumping System: The system reaches vacuum levels down to 10⁻⁶ torr and removes reactive gases that could contaminate materials

- Heating Elements: The resistance heating systems (with induction options available) can reach temperatures from 1200°C to 2300°C

- Hydraulic Pressure System: The system delivers forces up to 60 tons with digital force control that ensures precise pressure application

- Graphite Dies and Punches: These primary tooling materials can handle both heat and pressure while forming the workpiece

- Computerized Control Systems: The PLC-based automation comes with programmable temperature curves and pressure profiles

The systems use a resilient H-frame design that shows minimal deflection even at maximum pressures and ensures uniform material compression.

Best Applications for Vacuum Hot Press Sintering Furnace

The technology works best with materials that don’t respond well to conventional sintering methods:

- Advanced Ceramics: These include industrial, transparent, and structural ceramics that just need exceptional density

- Powder Metallurgy: This covers refractory metals and superalloys

- Composite Materials: The process works with ceramic-metal and carbon composites

- Nanomaterials Research: This includes materials where fine-grained microstructures must stay intact

The process becomes essential for boron carbide ceramics, which only reach 80-87% density at atmospheric pressure even at extreme temperatures of 2250-2300°C.

Advantages of Vacuum Hot Press Sintering Furnace

The pressure-vacuum combination gives several key benefits:

- Superior Material Density: The process reaches near-theoretical density (often 99.8%) by physically eliminating internal pores

- Reduced Processing Temperature: The furnace works at 200-400°C lower than conventional sintering with better results

- Enhanced Purity: The vacuum environment keeps oxidation and contamination away

- Microstructure Control: The process stops grain growth and coarsening while preserving nanoscale properties

- Complex Shape Capability: You can form materials into thin-walled tubes and complex shapes that conventional methods can’t handle

Limitations of Vacuum Hot Press Sintering Furnace

The technology faces some challenges:

- High Acquisition and Operation Costs: The complex mix of vacuum, heating, and hydraulic systems makes it expensive

- Extended Processing Time: Complete vacuum cycles take longer, which reduces throughput

- Geometry Constraints: The process usually works only with simple shapes like disks, blocks, and cylinders

- Technical Expertise Requirements: The core team must understand how thermal, vacuum, and mechanical systems work together

Vacuum Hot Press Sintering Furnace Pricing

Prices vary a lot based on specifications:

- Entry-level laboratory systems: $15,000-$25,000

- Mid-range production equipment: $40,000-$50,000

- Advanced systems with specialized capabilities: $50,000-$81,000+

The price depends on maximum temperature capability, chamber dimensions, force capacity, and control system sophistication.

Ideal Use Cases for Vacuum Hot Press Sintering Furnace

The technology becomes crucial for specific applications:

- Transparent Ceramics: The process achieves optical-grade transparency by removing all porosity (≥85% transmittance)

- Ultra-Hard Materials: You can process boron carbide and similar ceramics for ballistic protection

- High-Performance Targets: The technology helps manufacture sputtering targets for semiconductor and display production

- Ceramic Bearing Components: Silicon nitride bearing balls with exceptional dimensional accuracy (≤0.5μm roundness) become possible

- Precision Optical Components: The process creates silicon carbide reflectors with λ/20 surface accuracy

Materials that cannot have any trace of porosity or impurity find their best solution in vacuum hot pressing.

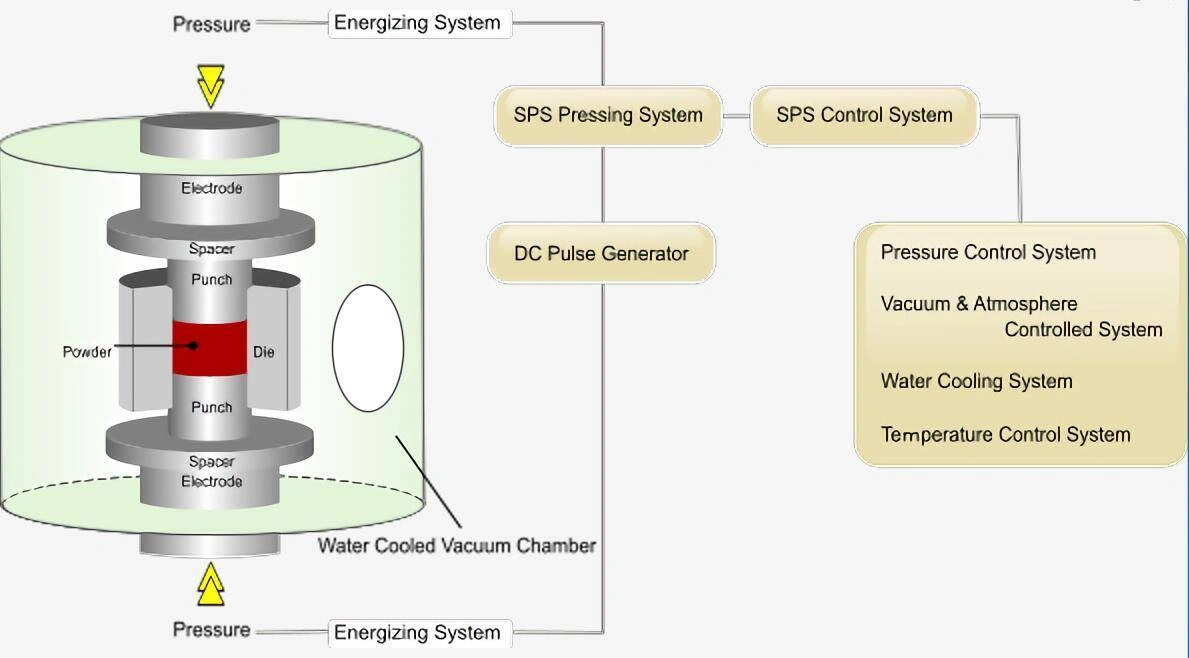

Spark Plasma Sintering (SPS) Furnace

Pulsed direct current technology serves as the foundation of Spark Plasma Sintering (SPS) furnaces, making it one of the quickest ways to achieve material densification in materials science. This innovative approach doesn’t just rely on external heat sources. It applies high-intensity, low-voltage pulsed current directly through conductive tooling and the material itself. The result is quick, uniform heating while pressure is applied.

Key Features of Spark Plasma Sintering (SPS) Furnace

SPS systems stand out from traditional sintering technologies with these distinctive components:

- Pulse DC Power Supply: Delivers high currents (750-1500A) with specialized control over pulse patterns

- Graphite Die Assembly: Conductive tooling that enables direct current flow and withstands high temperatures up to 2500°C

- Uniaxial Pressure System: Applies forces typically between 25-150 MPa during sintering

- Vacuum Chamber: Maintains vacuum levels in the 10⁻³ Torr range with options for various atmospheres

- Advanced Control Systems: PLC-based automation with easy-to-use interfaces for precise parameter management

- Water Cooling System: Detailed cooling with temperature detection and pressure monitoring

These systems can heat up to 1000°C/min, which creates completely different sintering dynamics compared to conventional methods.

Best Applications for Spark Plasma Sintering (SPS) Furnace

SPS technology works well with many material types:

- Nanomaterials that need grain size preservation

- Functionally gradient materials with varying sintering requirements

- Intermetallic compounds with high melting points

- Advanced ceramics achieving near-theoretical density

- Composite materials with complex phase structures

- Thermoelectric conversion elements (SiGe, PbTe, BiTe)

- Refractory materials that are hard to densify

Advantages of Spark Plasma Sintering (SPS) Furnace

SPS brings significant improvements over traditional sintering methods:

- Dramatically Reduced Processing Time: Sintering takes minutes instead of hours

- Lower Sintering Temperatures: Gets better results at 200-500°C below conventional sintering temperatures

- Superior Microstructure Control: Stops grain growth and preserves nanoscale features

- Energy Efficiency: Targets energy exactly where needed instead of heating the entire chamber

- Improved Material Properties: Creates finer grain sizes with better mechanical, thermal, and electrical characteristics

- Near-Theoretical Density: Achieves relative densities close to 100% even with nanomaterials

Limitations of Spark Plasma Sintering (SPS) Furnace

The technology comes with several challenges:

- High Acquisition Cost: Equipment needs substantial original investment

- Scalability Issues: Production capacity limits industrial-scale manufacturing

- Thermal Gradients: Uneven heating can create thermal shock in sintered materials

- Specialized Expertise Required: The core team must understand complex parameter relationships

- Tooling Costs: Graphite dies and punches add ongoing expenses

Spark Plasma Sintering (SPS) Furnace Pricing

System prices vary based on specifications:

- Laboratory-scale units: $5,688 to $22,588

- Mid-range production equipment: $20,000 to $35,000

- Advanced systems with specialized capabilities: $37,500 to $166,000

Maximum temperature capability, chamber size, pressure capacity, power supply specifications, and automation level affect the final cost.

Ideal Use Cases for Spark Plasma Sintering (SPS) Furnace

The technology shines in specific applications:

- Aerospace Components: Creates lightweight, high-strength materials for extreme environments

- Automotive Applications: Makes advanced ceramics for braking systems and sensors

- Electronic Materials: Develops next-generation semiconductors and thermoelectric materials

- Nuclear Industry: Produces radiation-resistant components for extreme conditions

- Biomedical Implants: Creates materials with precise biocompatibility

- Hard-to-Sinter Materials: Processes refractory compounds like borides, nitrides, and carbides

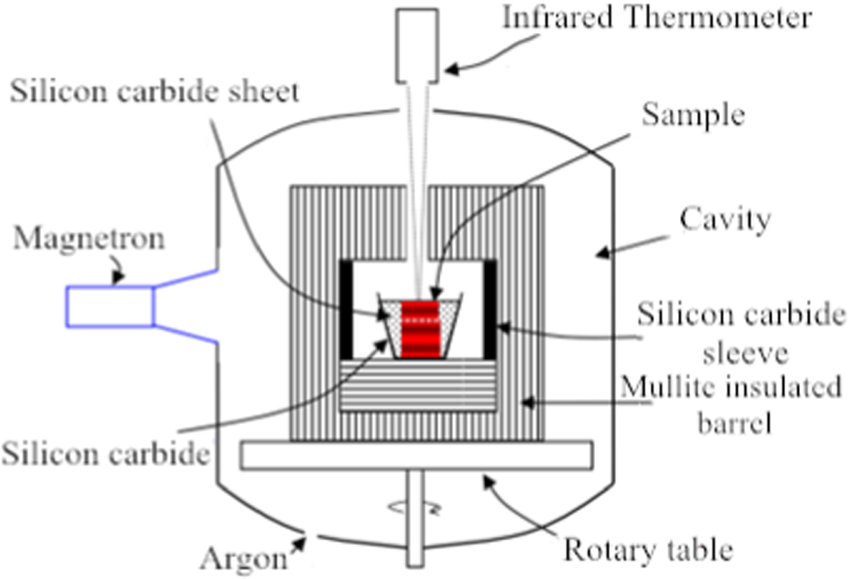

Microwave Vacuum Sintering Furnace

Microwave vacuum sintering furnaces have changed the way we approach sintering through their volumetric heating technology. These furnaces energize materials from within, unlike traditional heating methods that depend on external heat sources and gradual conduction. This creates uniform heating throughout the sample [5]. The technology is now a cornerstone of advanced material processing.

Key Features of Microwave Vacuum Sintering Furnace

These furnaces combine several sophisticated components:

- High-performance industrial microwave sources (2.45 GHz) that adjust power up to 6 kilowatts

- Double-layer water-cooled, vacuum-sealed stainless steel chambers

- Advanced vacuum systems that reach pressures below 10⁻³ Pa

- Imported high-precision infrared thermometers that measure sample temperature directly

- Embedded microcomputer temperature control systems with multiple operation modes

- Intake and outlet channels for inert gas protection with controllable gas flow

The systems reach maximum working temperatures of 1600°C and maintain temperature control precision of ±1°C [4].

Best Applications for Microwave Vacuum Sintering Furnace

These furnaces work best with:

- Powder metallurgy materials (iron-based, copper-based, and titanium)

- Magnetic materials (hard magnetic, soft magnetic, metal magnetic)

- Various ceramics (structural, varistor, thermistor, piezoelectric, dielectric)

- Carbon materials and catalysts

- Nanomaterials that need preserved grain structures

Advantages of the Microwave Vacuum Sintering Furnace

The technology offers clear benefits over traditional methods:

- Ultra-rapid heating with shorter holding times

- Processing times and energy use drop by a lot

- Better microstructural characteristics and mechanical properties

- More even heating leads to finer grains and denser microstructure

- Lower processing temperatures than conventional methods

- Improved sintering efficiency and better energy conversion

Limitations of the Microwave Vacuum Sintering Furnace

The technology faces some challenges:

- Higher original costs than traditional resistance-heated furnaces

- Materials must be carefully characterized since they don’t all respond to microwave energy the same way

- Complex operation that just needs more expertise

- Cooling issues might require extra cooling systems

- Heating zones are limited (usually around Φ110x100mm)

Microwave Vacuum Sintering Furnace Pricing

Prices change based on features and capabilities:

- Lab units cost between $100,000-$950,000

- HAMiLab-HV3 and HAMiLab-HV6 models come at different price points

- 2KW, 3KW, and 6KW microwave power options are available at various price levels

The cost depends on maximum temperature capability, chamber size, vacuum level, and control system complexity.

Ideal Use Cases for Microwave Vacuum Sintering Furnace

This technology is a great fit for:

- Metal powder materials that need nitridizing and carbonizing

- Neodymium iron boron and other advanced magnetic materials

- Research that needs quick experimentation with various materials

- Production of advanced ceramics with superior properties

- Manufacturing high-performance materials where microstructural control matters most

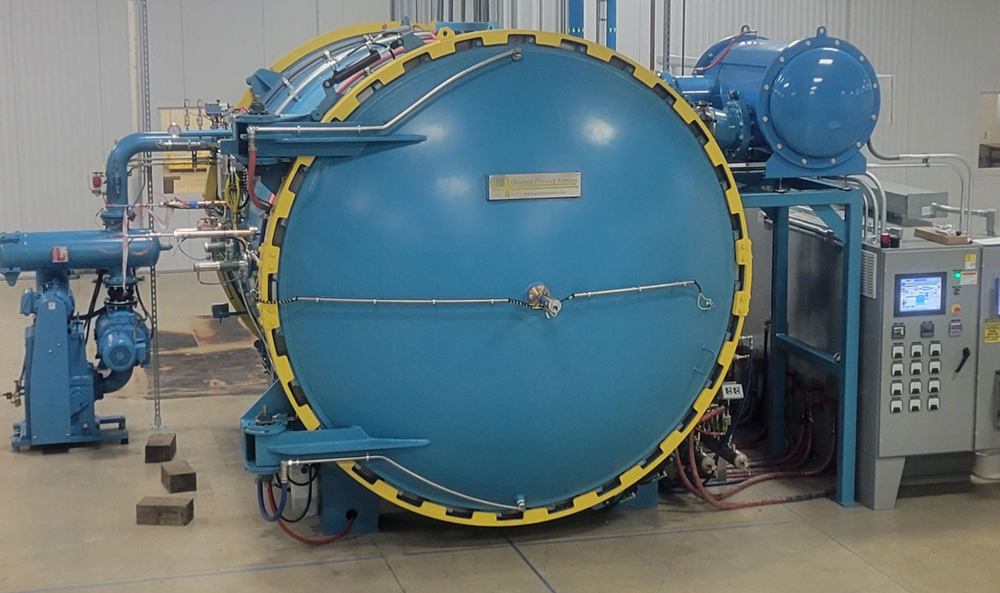

High-Vacuum Sintering Furnace

Ultra-high vacuum environments are the foundations of high vacuum sintering furnaces. These furnaces create exceptional material purity by removing all atmospheric gasses. The thermal processing systems work at vacuum levels down to 10⁻⁵ Pa. This creates perfect conditions for reactive materials and precision components where even tiny contamination could hurt performance.

Key Features of High-Vacuum Sintering Furnace

You’ll find two main types of high vacuum sintering furnaces: vertical and horizontal designs. Each design has its own benefits for specific materials. The core components include:

- Double-layer water-cooled stainless steel vacuum chambers

- Advanced pumping systems that keep pressures below 10⁻³ Pa

- Precision heating elements that reach 2200°C

- Smart temperature control systems with ±5°C uniformity

- Loading capacity from 75kg to 2000kg based on model specs

Best Applications for High Vacuum Sintering Furnace

These systems work best with materials that need exceptional environmental control:

- Rare refractory metals and alloys (tungsten, molybdenum, tungsten-copper)

- Samarium cobalt and other permanent magnet materials

- Cemented carbides for cutting tools and wear components

- Advanced ceramics including aluminum nitride and silicon nitride

- Specialty electronic components including substrates and sensors

Advantages of High Vacuum Sintering Furnace

High vacuum sintering brings several key benefits:

- Removes all oxidation by eliminating reactive gasses

- Pulls out trapped gasses between powder particles to increase final density

- Makes liquid phase sintering better through atomically clean surfaces

- Delivers exceptional material purity needed for high-performance uses

- Ensures consistent results through precise parameter control

Limitations of High Vacuum Sintering Furnace

The technology comes with some challenges:

- High upfront investment costs

- Long pump-down times that extend overall cycles

- Complex vacuum systems and seals need regular maintenance

- Operators need technical expertise for troubleshooting

- Materials with high vapor pressure elements face restrictions

High Vacuum Sintering Furnace Pricing

Prices vary widely based on specifications, usually between $400,000 and $1.5 million. Cost depends on:

- Temperature uniformity needs (±3°C vs. ±5°C)

- Maximum temperature capabilities

- Vacuum level specifications (10⁻¹Pa, 10⁻³Pa, 10⁻⁵Pa)

- Protective atmosphere requirements

- Component configuration (domestic vs. imported)

Ideal Use Cases for High Vacuum Sintering Furnace

These systems are vital for:

- Powder metallurgy components that need maximum density and strength

- Fine ceramic components in electronic and optical applications

- High-performance electronic components including MLCC and LTCC

- Aerospace components that need exceptional material integrity

- Semiconductor industry materials where purity affects performance

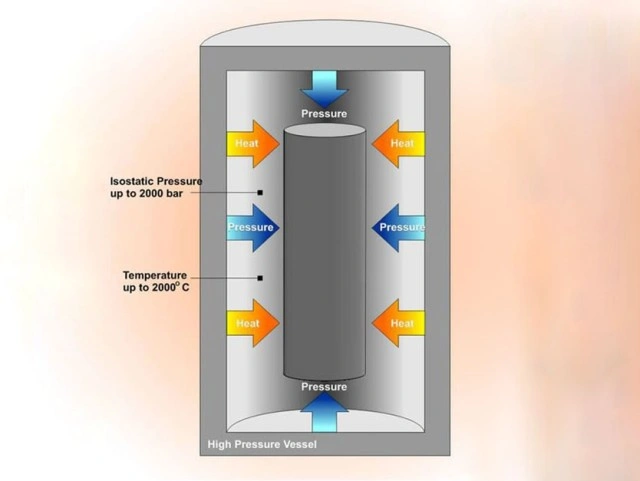

Hot Isostatic Pressing (HIP) Furnace

Hot Isostatic Pressing (HIP) furnaces stand out from other sintering technologies because they combine extreme pressure with high temperature. These systems create materials with exceptional density and performance by exposing components to high temperatures and isostatic gas pressure inside a high-pressure containment vessel.

Key Features of Hot Isostatic Pressing (HIP) Furnace

A HIP unit works with these core components:

- Pressure Vessel: High-strength cables wrap around it to stop crack spreading

- High-Temperature Furnace: Reaches temperatures up to 2000°C

- Pressurizing Gas System: We used argon at pressures from 50.7-310.3 MPa (7,350-45,000 psi)

- Cooling Systems: Modern units come with Uniform Rapid Cooling (URC) technology

- Control Systems: They manage pressure-temperature profiles throughout cycles precisely

Best Applications for Hot Isostatic Pressing (HIP) Furnace

HIP furnaces work best with:

- Additively manufactured parts that need densification

- Powder metallurgy materials from hard-to-forge compositions

- Investment castings with internal porosity

- Metal matrix composites and ceramics need maximum density

Advantages of Hot Isostatic Pressing (HIP) Furnace

HIP technology gives these strong benefits:

- Removes internal voids through plastic deformation, creep, and diffusion bonding

- Makes fatigue resistance and mechanical properties better

- Reaches near theoretical density (up to 100%)

- Creates even microstructure with minimal property variation

Limitations of Hot Isostatic Pressing (HIP) Furnace

The technology comes with these challenges:

- High original investment in equipment and strong infrastructure

- Batch processing limits production output

- Need for specialized expertise

- Long cycle times for complete processing

Hot Isostatic Pressing (HIP) Furnace Pricing

Prices vary based on specifications:

- Laboratory-scale systems: $3,000-$12,000

- Mid-range production units: $23,000-$76,800

- Large industrial systems: $108,170+

Ideal Use Cases for Hot Isostatic Pressing (HIP) Furnace

HIP furnaces are a great way to get results in:

- Aerospace components (turbine blades, critical structural parts)

- Medical implants that need biocompatibility

- Automotive performance components

- Energy industry applications (turbines, subsea components)

- Defense and nuclear industry critical parts

Comparison Table

| Furnace Type | Maximum Temperature | Key Applications | Main Advantages | Notable Limitations | Price Range |

|---|---|---|---|---|---|

| Vacuum Resistance | Up to 3000°C | Cemented carbide, ceramics, magnetic materials, refractory metals | Superior material purity, improved density, excellent surface quality | High equipment cost, high energy consumption, complex maintenance | $55,000 – $200,000+ |

| Vacuum Induction | Up to 2000°C | Reactive metals, superalloys, magnetic materials, rare earth metals | Rapid heating, homogeneous structure, precise composition control | High upfront investment, requires expertise, material restrictions | $70,000 – $1,000,000+ |

| Vacuum Hot Press | 1200°C – 2300°C | Advanced ceramics, powder metallurgy, composite materials, nanomaterials | Near-theoretical density (99.8%), lower processing temperature | High costs, longer processing time, geometry constraints | $15,000 – $81,000+ |

| Spark Plasma Sintering | Up to 2500°C | Nanomaterials, functionally gradient materials, advanced ceramics | Rapid processing, lower sintering temperatures, superior microstructure | High purchase cost, scaling difficulties, thermal gradients | $5,688 – $166,000 |

| Microwave Vacuum | Up to 1600°C | Powder metallurgy, magnetic materials, ceramics, carbon materials | Ultra-rapid heating, energy efficient, uniform heating | Higher capital costs, complex operation, limited heating zones | $100,000 – $950,000 |

| High Vacuum | Up to 2200°C | Rare refractory metals, permanent magnets, cemented carbides | Complete oxidation elimination, superior wetting, high purity | Large investment, longer cycle times, complex maintenance | $400,000 – $1.5M |

| Hot Isostatic Pressing | Up to 2000°C | Additive manufactured parts, powder metallurgy, investment castings | Near 100% density, better fatigue resistance, uniform microstructure | High investment costs, batch processing limits, long cycle times | $3,000 – $108,170+ |

Conclusion

The right vacuum sintering furnace choice depends on your material needs, production targets, and budget. Different furnaces shine in specific applications, making this choice vital to manufacturing success. Vacuum resistance furnaces work best with cemented carbides and ceramics, while induction systems produce better results for reactive metals and superalloys. Hot press technology achieves remarkable density for complex materials but costs more to run.

Temperature range plays a vital role in the decision. Microwave systems operate at 1600°C, while specialized resistance furnaces can reach 3000°C. Manufacturers need to weigh these capabilities against costs, which range from $3,000 for basic lab units to industrial systems that cost over $1.5 million.

Material purity needs help narrow down the options. High vacuum and hot isostatic pressing systems achieve near-theoretical density – a must for aerospace and medical parts, though they command premium prices. Spark plasma sintering delivers excellent results with nanomaterials and might cost less to acquire.

Production speed directly impacts efficiency. Microwave and spark plasma technologies cut cycle times dramatically compared to standard methods, though they might cost more upfront than traditional furnaces. The boost in throughput and lower energy use often justify the higher initial investment.

New advances keep expanding what vacuum sintering can do in many industries. Advanced ceramics, powder metallurgy, and additive manufacturing sectors benefit greatly from these specialized heating systems. Precise control of temperature, pressure, and atmospheric conditions lets manufacturers create parts with properties that were impossible before.

The seven furnace types discussed in this piece represent the most popular technologies in 2025’s manufacturing world. Their unique capabilities help engineers optimize material properties for demanding applications in aerospace, automotive, medical, and electronic sectors. The right match between furnace technology and manufacturing needs determines how well the final components perform.

Key Takeaways

Understanding the seven most utilized vacuum sintering furnace types enables manufacturers to make informed decisions that directly impact product quality, production efficiency, and investment returns.

• Match furnace type to material requirements: Vacuum resistance excels for ceramics (up to 3000°C), while induction systems optimize reactive metals and superalloys processing.

• Balance performance with investment costs: Entry-level systems start at $3,000, but specialized industrial units can exceed $1.5 million depending on capabilities.

• Consider processing speed for production efficiency: Microwave and spark plasma technologies reduce cycle times dramatically compared to conventional methods.

• Prioritize material purity for critical applications: High vacuum and HIP systems achieve near-theoretical density essential for aerospace and medical components.

• Evaluate temperature capabilities against application needs: Systems range from 1600°C (microwave) to 3000°C (resistance), directly affecting material processing possibilities.

The right vacuum sintering furnace selection ultimately determines manufacturing success, with each technology offering distinct advantages for specific materials and production goals. Advanced control over temperature, pressure, and atmospheric conditions enables creation of components with previously unattainable performance characteristics across demanding industrial sectors.

FAQs

Q1. What are the main types of vacuum sintering furnaces used in 2025? The seven most utilized vacuum sintering furnace types in 2025 are vacuum resistance, vacuum induction, vacuum hot press, spark plasma sintering, microwave vacuum, high vacuum, and hot isostatic pressing furnaces. Each type offers unique advantages for specific materials and applications.

Q2. How do vacuum sintering furnaces improve material properties? Vacuum sintering furnaces enhance material properties by eliminating oxidation, achieving near-theoretical density, and creating uniform microstructures. They enable precise control over temperature, pressure, and atmospheric conditions, resulting in components with superior mechanical properties, purity, and performance characteristics.

Q3. What factors should be considered when choosing a vacuum sintering furnace? Key factors to consider include maximum temperature capabilities, material requirements, production goals, budget constraints, and processing speed. Additionally, the specific application, desired material purity, and the level of operational expertise required should be taken into account.

Q4. How do the costs of different vacuum sintering furnaces compare? Costs vary widely based on furnace type and capabilities. Entry-level laboratory systems can start around $3,000, while advanced industrial units may exceed $1.5 million. Microwave and spark plasma systems often have higher initial costs but can offer efficiency gains through reduced cycle times.

Q5. Which industries benefit most from vacuum sintering technology? Vacuum sintering technology is crucial for industries requiring high-performance materials, including aerospace, automotive, medical devices, electronics, and energy sectors. It’s particularly valuable for manufacturing advanced ceramics, powder metallurgy components, and parts produced through additive manufacturing that require densification.