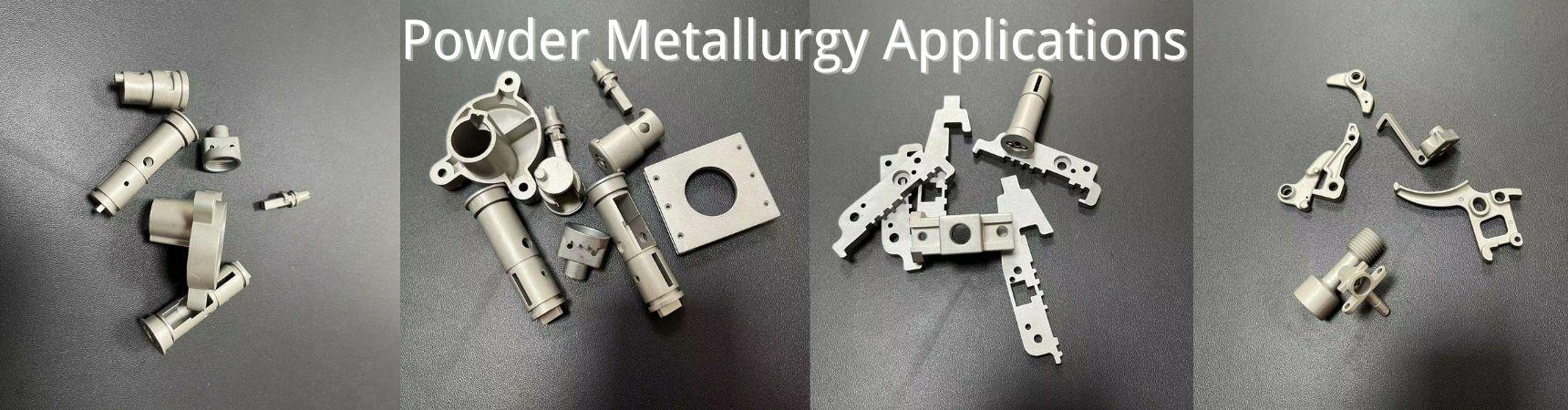

Introduction

Powder metallurgy (PM) is a versatile manufacturing process known for producing complex shapes with high precision and superior material properties. This article delves into five key applications of powder metallurgy, emphasizing its advantages and specific use cases in the automotive, aerospace, medical, electronics, and industrial machinery sectors.

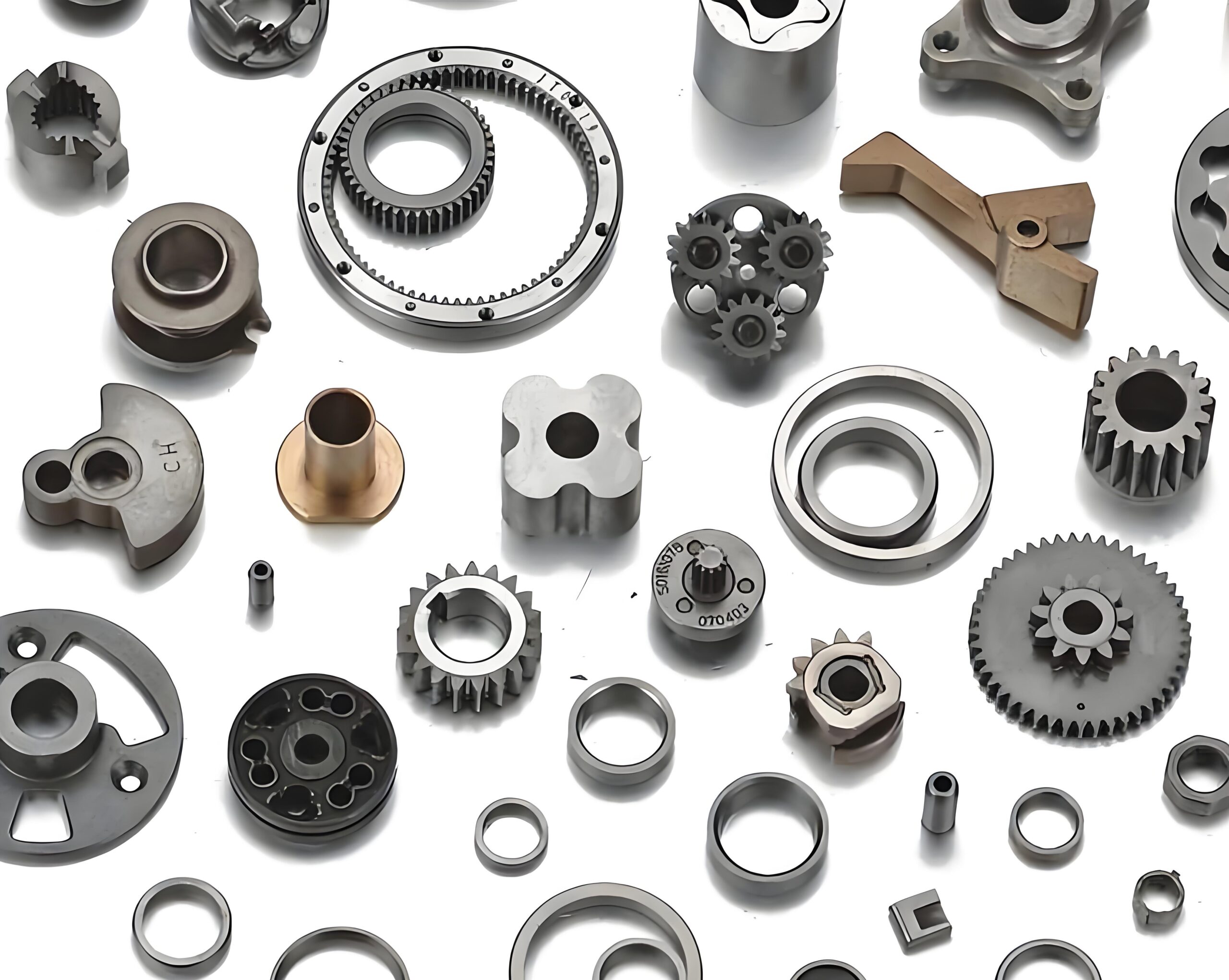

Automotive Industry

Engine Components

Manufacturing Efficiency

Powder metallurgy is extensively used to produce engine components such as connecting rods, gears, and bearings. The process ensures high production efficiency and consistency, which are crucial for automotive manufacturing.

Enhanced Performance

PM components exhibit excellent mechanical properties, including high strength and wear resistance, essential for the demanding conditions within an engine.

Transmission Parts

Precision and Durability

Transmission parts made using powder metallurgy benefit from the process’s precision, resulting in highly durable components that improve the overall reliability and performance of the vehicle’s transmission system.

Cost-Effectiveness

The ability to produce complex shapes with minimal material waste makes PM a cost-effective solution for manufacturing transmission parts.

Aerospace Industry

Structural Components

Lightweight Materials

In the aerospace industry, the need for lightweight yet strong materials is paramount. Powder metallurgy allows for the use of advanced materials such as titanium alloys, providing the necessary strength-to-weight ratio for structural components.

High-Temperature Performance

PM components used in aerospace applications can withstand high temperatures and harsh environments, making them ideal for critical structural elements in aircraft and spacecraft.

Engine Parts

Precision Engineering

Aerospace engines require parts with precise dimensions and high tolerance levels. Powder metallurgy ensures the production of these high-precision components, contributing to the overall efficiency and performance of the engines.

Material Innovation

The ability to use innovative materials through powder metallurgy helps create engine parts that offer superior performance characteristics, such as improved fuel efficiency and reduced emissions.

Medical Industry

Implants and Prosthetics

Customization and Biocompatibility

Powder metallurgy is used to produce customized medical implants and prosthetics. The process allows for precise control over the material composition, ensuring biocompatibility and reducing the risk of rejection by the body.

Complex Geometries

The ability to create complex geometries through PM enables the production of implants and prosthetics that closely mimic the natural anatomy, improving patient outcomes.

Surgical Instruments

High Precision and Sterility

Surgical instruments manufactured using powder metallurgy benefit from high precision and excellent surface finishes, which are crucial for ensuring sterility and effectiveness during medical procedures.

Durability

PM surgical instruments are known for their durability and resistance to wear and corrosion, making them reliable tools for repeated use in medical settings.

Electronics Industry

Magnetic Components

High Performance

Powder metallurgy is used to manufacture magnetic components such as soft magnetic composites and permanent magnets. These components are essential for various electronic devices, offering high performance and efficiency.

Miniaturization

The PM process allows for the production of small, intricate magnetic components that are essential for the miniaturization of electronic devices, contributing to the development of more compact and efficient electronics.

Thermal Management

Heat Sinks

In electronics, effective thermal management is crucial for the performance and longevity of devices. Powder metallurgy is used to create heat sinks with high thermal conductivity, ensuring efficient heat dissipation.

Customized Solutions

The ability to produce customized thermal management solutions through PM allows for tailored designs that meet the specific needs of different electronic applications, enhancing overall device performance.

Industrial Machinery

Tooling and Dies

High Wear Resistance

Powder metallurgy is ideal for producing tooling and dies that require high wear resistance. The process allows for the use of hard materials that can withstand the demanding conditions of industrial manufacturing.

Precision and Consistency

The precision offered by PM ensures that tooling and dies have consistent dimensions and high-quality surface finishes, which are essential for maintaining the accuracy of industrial machinery.

Bearings and Filters

Porosity Control

PM is used to manufacture porous bearings and filters that benefit from controlled porosity levels. This control is crucial for applications that require specific flow rates and filtration efficiency.

Long Service Life

The durability of PM bearings and filters ensures a long service life, reducing the need for frequent replacements and maintenance in industrial machinery.

Conclusion

Powder metallurgy offers numerous advantages, including high precision, material efficiency, and the ability to produce complex geometries. Its applications across various industries—automotive, aerospace, medical, electronics, and industrial machinery—demonstrate its versatility and effectiveness in meeting diverse manufacturing needs. As technology advances, the scope of powder metallurgy is expected to expand further, offering even more innovative solutions for modern manufacturing challenges.