3D Printing In The Future Of Automotive Design And Manufacturing

In the context of popularizing computer digital networking, mechanical and electronic parts have begun to diversify with higher quality, lower cost, and more diverse styles. In this context, additive manufacturing 3D printing technology has also been developed rapidly and is widely used in the field of automotive parts processing and manufacturing. At the same time, with the “Made in China 2025” plan, lightweight, personalized, and intelligent development will become the future development trend in the field of automotive design and manufacturing.

Advantages Of 3d Printing In the Automotive Industry

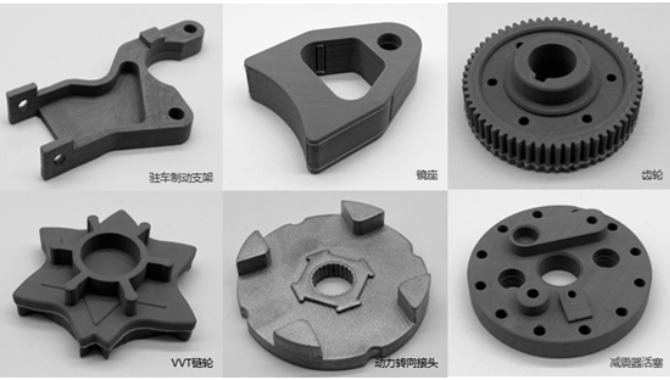

3D printing is also favored by automobile manufacturers because of its ability to manufacture extremely complex structural parts and achieve a series of advantages such as personalized and rapid moldless molding. It can not only shorten the development cycle of automobiles but also save the cost of automobile production and get rid of the reliance on molds in traditional automobile manufacturing, which is of great significance in promoting the development of the automobile industry. Its main advantages are shown as follows:

- First, the traditional mechanical processing method mainly contains four types of turning, milling, planing and grinding, the common feature of which is reduced material processing, while 3D printing technology uses additive processing method, which can save a lot of raw materials and save production costs;

- Second, the use of 3D printing technology, no mold manufacturing, tool clamping, etc.. The high degree of technology integration can shorten the product development cycle and improve productivity.

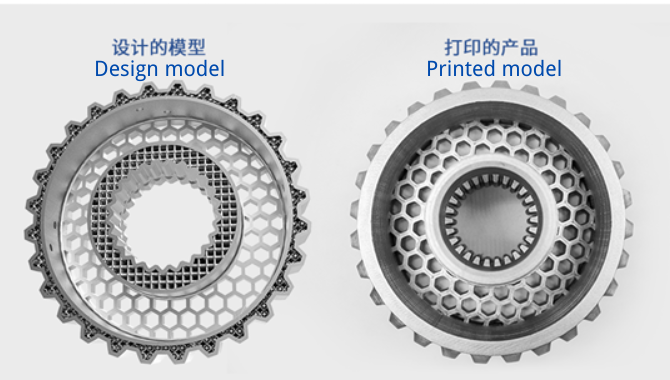

- Third, unlike casting and forging parts, 3D printing can manufacture products with complex shapes and structures based on models in computers, and can achieve small batch production.

- Fourth, 3D printing can be fully structural optimization design (such as hollow sandwich, hollow dot matrix, integrated structure, generative anisotropic topology, etc.), can be manufactured better performance, lighter weight parts. Combining multiple parts into a single integrated component is possible, reducing installation steps. Especially for electric vehicles, lightweight becomes more important to increase the range. As a result, for some parts, 3D printing may cost more than parts made by traditional processes, but the overall cost is lower when the cost of later use is considered.

Future of 3d Printing Automotive Industry

Nowadays 3D printing has come into our daily lives, in all aspects of our life work to provide convenience, such as education, medical, aerospace, etc. The automotive industry has become one of the main industries of 3D printing applications, so for the future, what are the applications of 3D printing in the automotive industry?

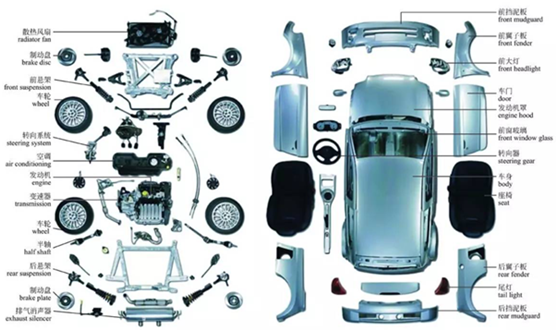

Digital spare parts warehouse

Because the car will be damaged and need repair, manufacturers in the production of cars will also produce a certain amount of spare parts to stock, and 4S stores, and auto repair stores will prepare some parts. However, because there are too many car parts, will lead to high inventory costs. The manufacturer may also re-produce due to the shortage of parts, resulting in the growth of the maintenance cycle. This is why many car manufacturers develop a unified standardized production platform, thereby reducing spare parts inventory, while responding to the main measures of different products’ after-sales operations.

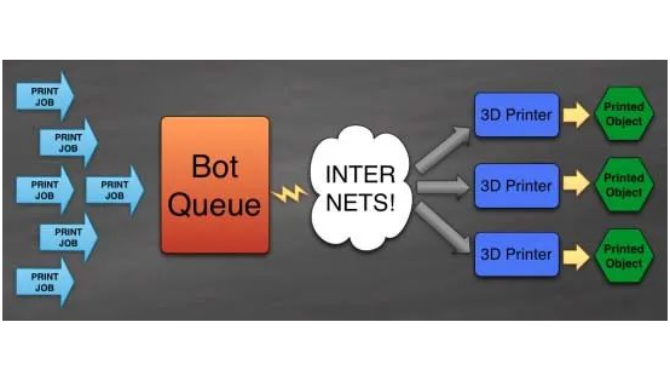

In the future, digital parts warehouses will become a new type of spare parts approach, where end service points can manufacture the required parts directly through 3D printing technology, making it possible to reduce inventory pressure and repair times.

New Product Development Certification( 3d Printing Automotive Parts )

As a product of modern industrial civilization, the development of automobiles from design to mass production requires the production of a large number of prototypes for product certification. Before 3D printing, these prototypes were made by hand, CNC and other methods.

And nowadays, in the R&D stage, a large number of prototypes are already made by 3D printing. With the progress of 3D printing technology, its advantages of short production cycle, high precision and low cost will be further highlighted.

3d Printing Mass Manufacturing ( 3d Printed Car Parts )

Due to the customization and personalization characteristics of 3D printing, which is also the main reason why it is not suitable for mass production, so the current manufacturing parts directly applied to mass-production cars or less, most of them are still used as test parts. For example, a variety of supercars, F1 cars, etc., as modified parts. Due to the high degree of customization and small molding restrictions, 3D printing can produce topologically optimized parts, which often have complex geometry, lighter and better performance than the original parts.

At present, there are already many head manufacturers in the automotive industry are increasing the research and development of 3D printing technology. In order to use 3D printing technology to mass produce parts to bring better performance to the car.

Distributed 3d printing Manufacturing

Distributed Manufacturing (DM) is locally based, small-scale, rapid design and production. It stems from the engineering ability to produce a small number of parts at as close to mass production cost as possible, rather than a high-volume, centralized production model. The automotive industry is a highly concentrated industry, with large numbers of parts being shipped to factories, assembled on production lines into complete vehicles, and shipped around the world for distribution. As a result, a large amount of transportation capacity needs to be used. 3D printing, on the other hand, allows for distributed production, 3D printing chassis and various parts locally and then assembling them.

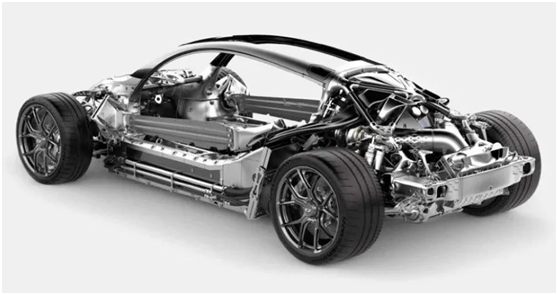

3D printing whole car

From the current point of view, printing the whole car from mass production is still some distance away, but over the years, a variety of 3D printing of cars, electric vehicles are also a lot. Current 3D printing technology, can already be used to print the whole car chassis, frame, doors, etc., and 3D printed chassis and other components can be integrated with multiple parts to achieve one piece of molding, not only to reduce assembly time, but also to enhance the solidity.

Although currently limited by the speed of printing, does not have the ability to mass production. However, when the printing speed and technology maturity is enhanced to a certain stage, 3D printing of complete vehicles will also shine into reality.