1.4021 material refers to a type of stainless steel known for its unique properties. This material plays a crucial role in various industrial applications due to its excellent mechanical strength and durability. Key properties of 1.4021 material include high resistance to wear and tear, making it suitable for demanding environments. Its versatility allows it to be utilized in a wide range of products and structures, enhancing both performance and longevity.

Key Takeaways

- 1.4021 material is a type of stainless steel known for its high strength and durability, making it ideal for demanding industrial applications.

- This material has excellent wear resistance, which enhances its performance and longevity in various products and structures.

- The mechanical properties of 1.4021 include a tensile strength of 450-650 MPa and a yield strength of up to 320 MPa, ensuring it can withstand significant stress.

- 1.4021 material has moderate corrosion resistance, particularly in low chloride environments, but may be susceptible to pitting in harsher conditions.

- The chemical composition of 1.4021 includes iron, chromium, and carbon, which contribute to its hardness and overall performance.

- Applications of 1.4021 material range from cutlery and surgical instruments to mechanical components and construction materials, showcasing its versatility.

- Cost-effectiveness is a key advantage of 1.4021 material, offering lower initial costs compared to higher-grade stainless steels without sacrificing essential properties.

- Proper heat treatment processes, such as annealing and quenching, are crucial for optimizing the hardness and toughness of 1.4021 material.

Specifications of 1.4021 Material

Mechanical Properties of 1.4021 Material

The mechanical properties of 1.4021 material are essential for its performance in various applications. This stainless steel exhibits impressive strength and durability. The following table summarizes the standard mechanical property values:

| Property | Value |

|---|---|

| Tensile Strength (MPa) | 450 – 650 |

| Yield Strength (0.2% Proof Stress) (MPa) | 280 (long), 320 (trans) |

| Elongation (%) | 20 |

In addition to these values, other notable mechanical properties include:

- Elastic (Young’s) Modulus: 190 GPa

- Fatigue Strength: 240 to 380 MPa

- Hardness: 44-50 HRC

These properties contribute to the material’s ability to withstand stress and deformation, making it suitable for demanding environments.

Physical Properties of 1.4021 Material

The physical properties of 1.4021 material further enhance its utility in industrial applications. Key characteristics include:

- Density: Approximately 7.8 g/cm³

- Melting Point: Ranges from 1400°C to 1450°C

- Thermal Conductivity: 25 W/m·K

These physical attributes ensure that 1.4021 material can perform effectively under various temperature conditions and maintain structural integrity.

Dimensional Standards for 1.4021 Material

1.4021 material adheres to specific dimensional standards, which facilitate its use in manufacturing and construction. Common product forms and sizes include:

| Specification | Details |

|---|---|

| Length | 2000 mm, 2440 mm, 2500 mm, 3000 mm, 6000 mm |

| Width | 1000 mm, 1219 mm, 1250 mm, 1500 mm, 2000 mm |

| Thickness | Ranging from 0.3 mm to 20 mm |

| Finish | Hot rolled plate (HR), Cold rolled sheet (CR), 2B, 2D, BA NO(8), SATIN (Met with Plastic Coated) |

These standards ensure that manufacturers can obtain 1.4021 material in the required dimensions for their specific applications, promoting efficiency and consistency in production.

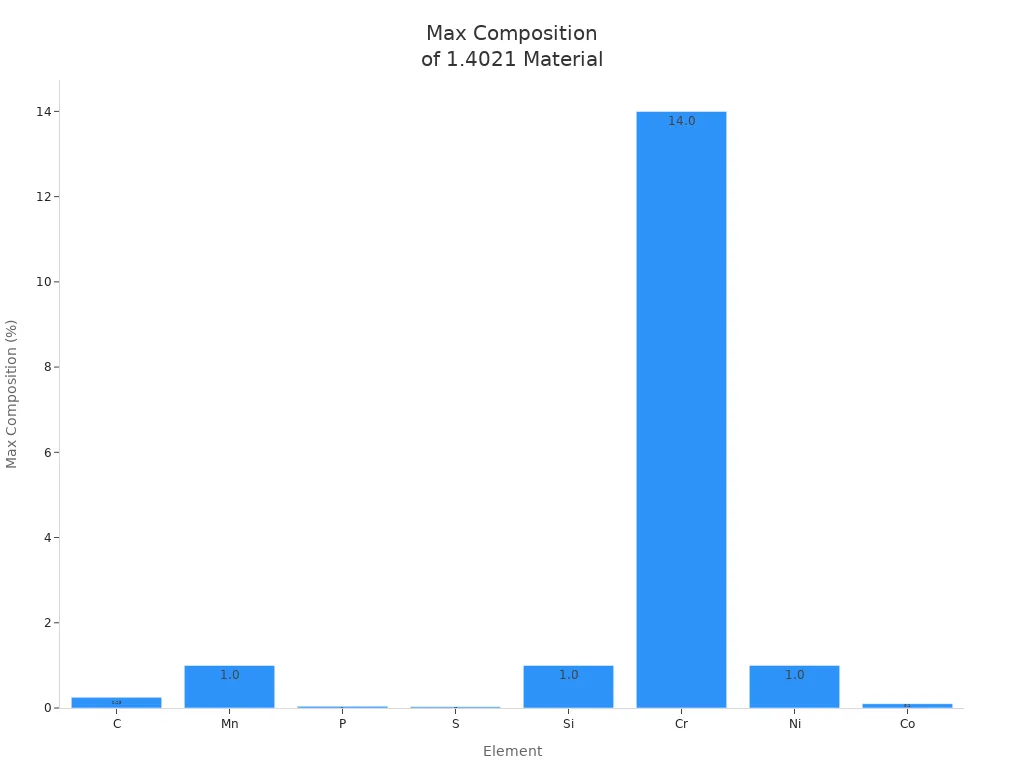

Chemical Composition of 1.4021 Material

The chemical composition of 1.4021 material significantly influences its properties and applications. This stainless steel primarily consists of iron, chromium, and carbon, among other elements. Understanding the elemental breakdown helps in assessing its performance in various environments.

Elemental Breakdown of 1.4021 Material

The typical chemical composition range for 1.4021 material according to industry standards is as follows:

| Element | Composition Range |

|---|---|

| Carbon (C) | 0.16 – 0.25 % |

| Silicon (Si) | max 1 % |

| Manganese (Mn) | max 1.5 % |

| Phosphorus (P) | max 0.04 % |

| Sulfur (S) | max 0.015 % |

| Chromium (Cr) | 12-14 % |

These elements contribute to the overall characteristics of 1.4021 material, particularly its corrosion resistance and mechanical strength. The presence of chromium, for instance, enhances its ability to resist oxidation and corrosion.

Comparison of 1.4021 Material with Other Stainless Steels

When comparing 1.4021 material with other stainless steels, such as 1.4301 and 1.4404, distinct differences in chemical composition emerge. The following table summarizes these differences:

| Material | Carbon Content | Chromium Content | Nickel Content | Molybdenum Content |

|---|---|---|---|---|

| 1.4021 | Higher | Lower | Lower | N/A |

| 1.4301 | Lower | Higher | Higher | N/A |

| 1.4404 | Lower | Higher | Higher | Present |

This comparison highlights that 1.4021 material has a higher carbon content, which can enhance its hardness but may reduce its corrosion resistance compared to the other grades. The lower chromium and nickel contents also indicate that 1.4021 material may be less resistant to certain corrosive environments.

In addition, the impurity limits for elements such as sulfur and phosphorus are critical for maintaining the quality of 1.4021 material. The maximum limits are as follows:

| Element | Maximum Limit |

|---|---|

| Phosphorus | 0.04% |

| Sulfur | 0.03% |

These limits ensure that the material maintains its integrity and performance in various applications.

Properties of 1.4021 Material

Corrosion Resistance of 1.4021 Material

Corrosion resistance is a critical property of 1.4021 material, particularly in various industrial applications. This stainless steel exhibits moderate corrosion resistance, especially in environments with low chloride concentrations. However, it is more susceptible to pitting and stress corrosion cracking in chloride-rich environments.

- In comparison to austenitic stainless steels like 1.4401 (AISI 316), which contain higher chromium and molybdenum content, 1.4021 material shows limited resistance to aggressive conditions.

- The following table summarizes the corrosion resistance characteristics of 1.4021 material compared to other martensitic stainless steels:

| Material | Carbon Content | Corrosion Resistance | Hardness and Strength |

|---|---|---|---|

| 1.4021 | Lower | Superior | Moderate |

| 1.4028 | Higher | Compromised | Higher |

This table highlights that while 1.4021 material offers superior corrosion resistance compared to some alternatives, it may not perform as well in highly corrosive environments.

Hardness and Strength of 1.4021 Material

The hardness and strength of 1.4021 material are significant factors that contribute to its suitability for various applications. This stainless steel achieves high hardness through specific heat treatment processes.

- Annealing: This process reduces hardness and enhances machinability.

- Quenching (Austenitizing and Quenching): Heating the material to high temperatures (e.g., 980–1050 °C) dissolves carbides, forming austenite. Rapid cooling transforms this into martensite, resulting in high hardness.

- Tempering: This step is crucial to reduce brittleness and internal stresses. Tempering typically occurs at temperatures between 150–700 °C, avoiding the brittle zone at 475 °C to maintain toughness.

The combination of these processes allows 1.4021 material to achieve a balance between toughness, strength, and hardness, making it suitable for demanding applications.

Thermal Conductivity of 1.4021 Material

Thermal conductivity is another important property of 1.4021 material. It influences how effectively the material can transfer heat, which is vital in various applications.

- The thermal conductivity of 1.4021 material at room temperature measures approximately 30 W/m·K.

- At elevated temperatures, this value may vary, but it remains within a range that supports effective heat transfer in industrial settings.

Understanding the thermal conductivity of 1.4021 material helps engineers and designers select appropriate materials for applications requiring efficient heat management.

Applications of 1.4021 Material

1.4021 material finds extensive use across various sectors due to its unique properties. Its mechanical strength, durability, and moderate corrosion resistance make it suitable for numerous applications.

Industrial Uses of 1.4021 Material

In industrial settings, 1.4021 material addresses specific performance requirements. The following table outlines common application areas and their respective performance needs:

| Application Area | Performance Requirements |

|---|---|

| Cutlery Manufacturing | Hardness, strength, and corrosion resistance |

| Medical Instruments | Mechanical properties and corrosion resistance |

| Mechanical Engineering | Balance of mechanical properties and durability |

These applications highlight the material’s ability to withstand demanding conditions while maintaining functionality.

Consumer Products Made from 1.4021 Material

1.4021 material is also prevalent in consumer products. Its properties make it ideal for various items used in everyday life. The table below illustrates typical consumer products and the properties that enhance their performance:

| Application Type | Properties |

|---|---|

| Kitchenware | High hardness, strength, moderate corrosion resistance |

| Cutlery | Durability, wear resistance, suitable for mild environments |

| Surgical instruments | Good balance between wear resistance and moderate corrosion resistance |

| Machine components | Suitable for gears, bolts, and nuts due to strength and hardness |

| Pumps, shafts, valves | Effective in applications needing strength and moderate corrosion resistance |

| Not suitable for seawater | Pitting corrosion occurs in seawater environments |

These products benefit from the material’s durability and resistance to wear, making them reliable choices for consumers.

Construction and Engineering Applications of 1.4021 Material

In construction and engineering, 1.4021 material plays a vital role. Its mechanical properties allow it to be used in various structural applications. Engineers often select this material for components that require strength and durability.

Applications include:

- Structural components: Used in frameworks and supports due to its strength.

- Fasteners: Ideal for bolts and screws that must endure high stress.

- Machinery parts: Commonly found in gears and shafts where wear resistance is crucial.

The versatility of 1.4021 material ensures its continued relevance in construction and engineering projects.

Advantages of 1.4021 Material

Cost-Effectiveness of 1.4021 Material

1.4021 material stands out for its cost-effectiveness compared to other stainless steels. While materials like 1.4404 may offer superior properties, they come with a higher processing cost, increasing by 20-30% due to their enhanced hardness. In contrast, 1.4021 material provides a more budget-friendly option without sacrificing essential performance characteristics.

- Initial Costs: Lower than 1.4404, making it accessible for various applications.

- Life Cycle Costs: Although 1.4404 reduces maintenance costs by 30-50% over 5-10 years, the initial investment in 1.4021 remains attractive for many users.

This balance between upfront costs and long-term performance makes 1.4021 a practical choice for industries seeking reliable materials without excessive expenditure.

Durability and Longevity of 1.4021 Material

The durability and longevity of 1.4021 material derive from several key factors:

| Factor | Description |

|---|---|

| High Hardness and Strength | The QT treatment increases hardness, making it suitable for durable and wear-resistant applications. |

| Wear Resistance | High hardness contributes to excellent wear resistance, ideal for repetitive use and friction. |

| Adequate Corrosion Resistance | Provides sufficient corrosion resistance for many applications, though not as high as austenitic steels. |

| Brittleness | Martensitic nature can lead to brittleness, affecting performance under sudden impacts. |

| Heat Treatment Sensitivity | Performance relies on proper heat treatment; incorrect methods can reduce effectiveness. |

| Limited Weldability | Complicates repairs; requires specialized techniques to maintain performance. |

| Maintenance Requirements | May need more frequent maintenance due to lower corrosion resistance. |

These factors collectively enhance the material’s performance in demanding environments, ensuring it meets the rigorous demands of industrial applications.

Versatility of 1.4021 Material in Applications

1.4021 material exhibits remarkable versatility across various sectors. Its properties allow it to excel in multiple applications, making it a preferred choice for manufacturers.

Common applications include:

- Cutlery

- Surgical instruments

- Industrial blades

- Valves and pumps

- Gears and bearings

Additionally, its adaptability extends to:

- Kitchenware

- Automotive industry

- Medical technology

- Mechanical engineering

- Petrochemical industry

- Architecture

This wide range of applications highlights the material’s ability to meet diverse performance requirements, solidifying its position as a valuable resource in both industrial and consumer markets.

In summary, 1.4021 material exhibits essential properties such as high strength, moderate corrosion resistance, and versatility. These characteristics make it valuable across various industries, including aerospace, automotive, and medical instrument production.

Looking ahead, the demand for 1.4021 material is projected to grow steadily, with an estimated compound annual growth rate (CAGR) of approximately 3-5%. By 2027, the martensitic stainless steel round bars market could reach a multi-billion dollar valuation.

Technological advancements, such as the use of environmentally friendly lubricants, will further enhance the performance of 1.4021 material in manufacturing processes. This evolution ensures that 1.4021 remains a critical resource in meeting the demands of modern applications.

FAQ

What is 1.4021 material commonly used for?

1.4021 material is widely used in cutlery, surgical instruments, and mechanical components. Its strength and durability make it suitable for applications requiring wear resistance and moderate corrosion resistance.

How does 1.4021 material compare to other stainless steels?

1.4021 material has higher carbon content than many stainless steels, enhancing hardness but potentially reducing corrosion resistance. It is less resistant to aggressive environments compared to austenitic grades like 1.4404.

Can 1.4021 material be welded?

Welding 1.4021 material can be challenging due to its martensitic structure. Specialized techniques are necessary to maintain performance and prevent brittleness. Preheating and post-weld heat treatment may be required.

What are the heat treatment options for 1.4021 material?

Heat treatment options for 1.4021 material include annealing, quenching, and tempering. These processes enhance hardness, strength, and toughness, allowing the material to meet specific application requirements.

Is 1.4021 material suitable for outdoor applications?

1.4021 material can be used outdoors but may not perform well in highly corrosive environments, such as coastal areas. Proper protective coatings can enhance its longevity in such conditions.

What are the maintenance requirements for products made from 1.4021 material?

Products made from 1.4021 material require regular cleaning to prevent corrosion. Avoid exposure to harsh chemicals and ensure proper storage to maintain their performance and appearance.

How does the cost of 1.4021 material compare to other stainless steels?

1.4021 material is generally more cost-effective than higher-grade stainless steels like 1.4404. Its lower initial costs make it an attractive option for various applications without sacrificing essential performance characteristics.

What factors influence the choice of 1.4021 material for a specific application?

Factors influencing the choice of 1.4021 material include mechanical strength, corrosion resistance, cost, and specific application requirements. Engineers assess these factors to determine the most suitable material for their needs.