The Best Worthy One-stop PM and MIM Manufacturer

JH MIM has Nearly 20 years of experience in the Metal injection molding and Powder metallurgy industry factories covers more than 18000 square meters, World class equipment and 150 skilled workers. Providing precision-engineered products to our global customers. Be your best Metal Injection Molding Manufacturer in China.

Who We Serve / Custom Metal Components

Hi-Tech MIM Manufacturing Equipment

Word Class Facilities Production

JH MIM manufacturing equipment is imported directly from Germany

- High Accurate Metal Injection Molding Machine.

- Vacuum Sintering Furnace.

- Sintering Furnace From Germany.

- Gas Hydraulic Machine.

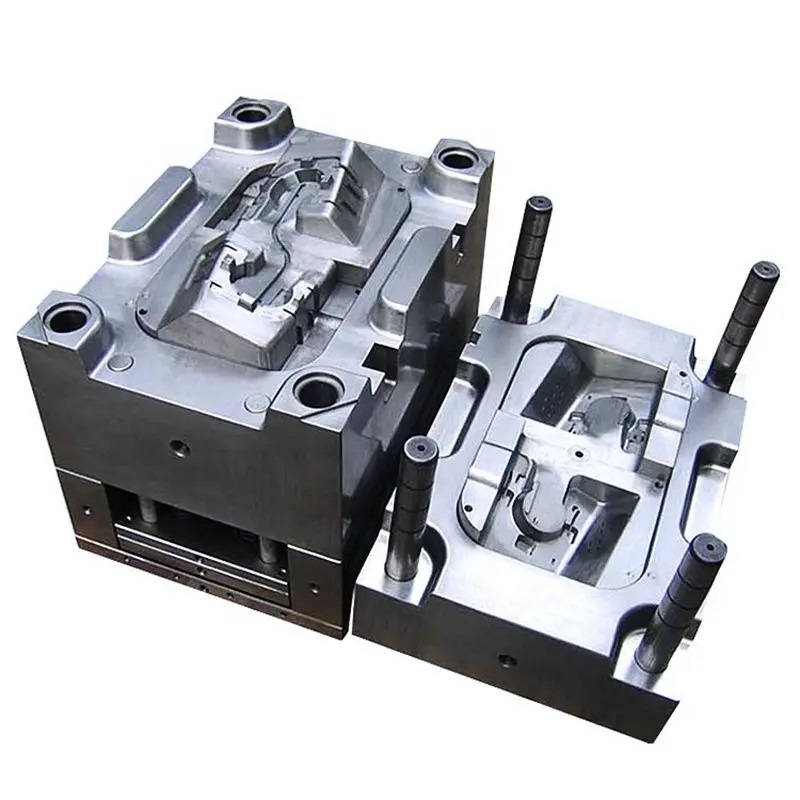

World Class Facilities Tooling

1.Swiss Agie Charmilles EDM

2.Sodick EDM

3.FANUC CNC

4.Sodick Wire Cutting Machine

5.Swiss Agie Charmilles CNC

6.Makino CNC

MIM Components

MIM parts are intricate metal components made using metal injection molding technology, a recently developed process for producing metal components. in contrast to traditional metalworking techniques like casting or forging. When producing small, intricately shaped metal parts in large quantities, metal injection molding performs better.

Similar to plastic injection molding and high-pressure die casting, metal injection molding is a procedure used to shape metal objects. Nonetheless, MIM components can achieve superior dimensional tolerance control and high mechanical qualities comparable to wrought materials.

Typically, MIM components have full density, which offers superior mechanical, corrosion-resistant, and hermetic sealing qualities. Furthermore, secondary processes like machining, heat treatment, and plating are simple to carry out.

Why JH MIM

- Nearly 20 years experience

- 18,000 square meter workshop

- World class equipment and test instruments

- 150+ workers and 10+ engineers

- 6S system ,20+ QC workers

- Reply your RFQ in 24 hours

- Offer quotations in 3 days

- Offer DFM reports in 7 days

- Molding make time 25-30 days

- Free warranty service in 1 year

Ability

- 20 years industry experience

- 10 years foreign trade export experience

- 50+ experienced engineers

- 18000+ square meters

- ISO 9001/ IATF 16949

- Faster quotations and DMF reports

- In-depth cooperation of world-renowned companies

Custom Any PM And MIM Parts for Your Project

Metal Injection Molding

An advanced metal manufacturing technique with high density, intricate geometries, and superior qualities is metal injection molding, or MIM. It is also a reasonably priced way to produce metal parts. Metal powder, injection molding, and sintering technologies are combined in this manufacturing process to ensure that MIM products can be complex, have great surfaces, and tight tolerances.

JH MIM can offer different material classifications for the metal injection molding process such as:MIM-4605, MIM-304 , MIM-316L, MIM-17-4Ph and MIM-420 ,are Widely used in the arms parts, industrial structural parts, gear parts, equipment parts and medical electronic equipment parts and so on.

What Our Customer Say

“We are a freezer manufacturer from Spain, and JH MIM provides door lock accessories for us; we have been working together for over ten years. We are confident in handing over our products to them because of good communication and consistent quality.”

“Even if there are occasional issues with products or delivery, they can find solutions quickly. They are competent. I enjoy collaborating with them!”